Isolation switch with arc extinguishing structure and moving contact assembly of isolation switch

An isolating switch and moving contact technology, which is applied to air switch parts, electrical switches, electrical components, etc., can solve the problems of insufficient arc extinguishing ability of the isolating switch, lack of high-parameter bus switching current switching ability, etc. Blocking effect, solving the lack of arc extinguishing ability, and promoting the effect of rapid extinguishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

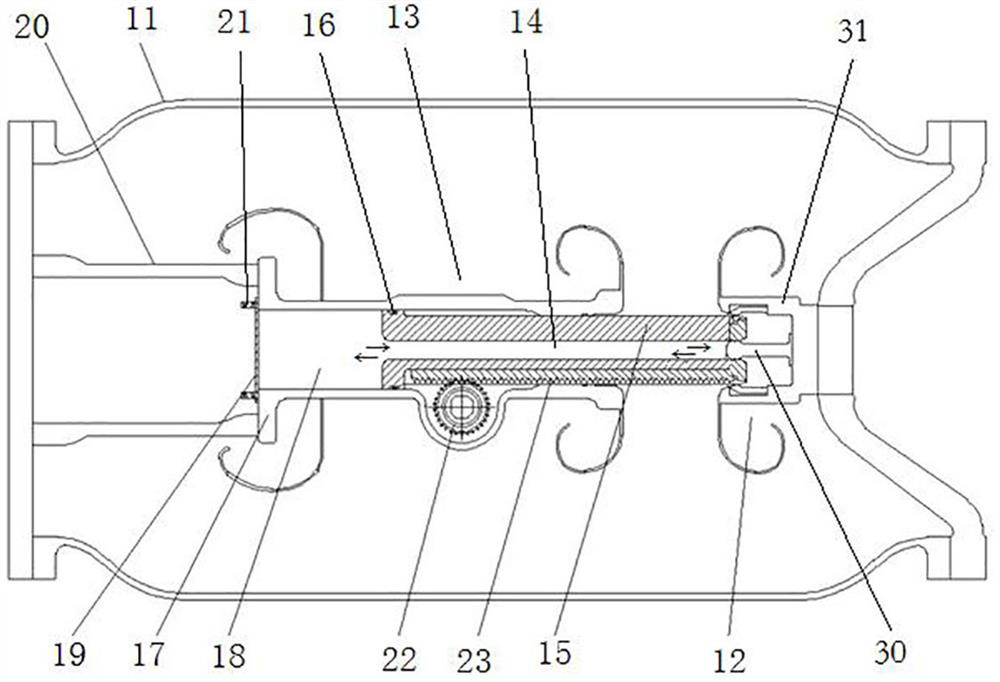

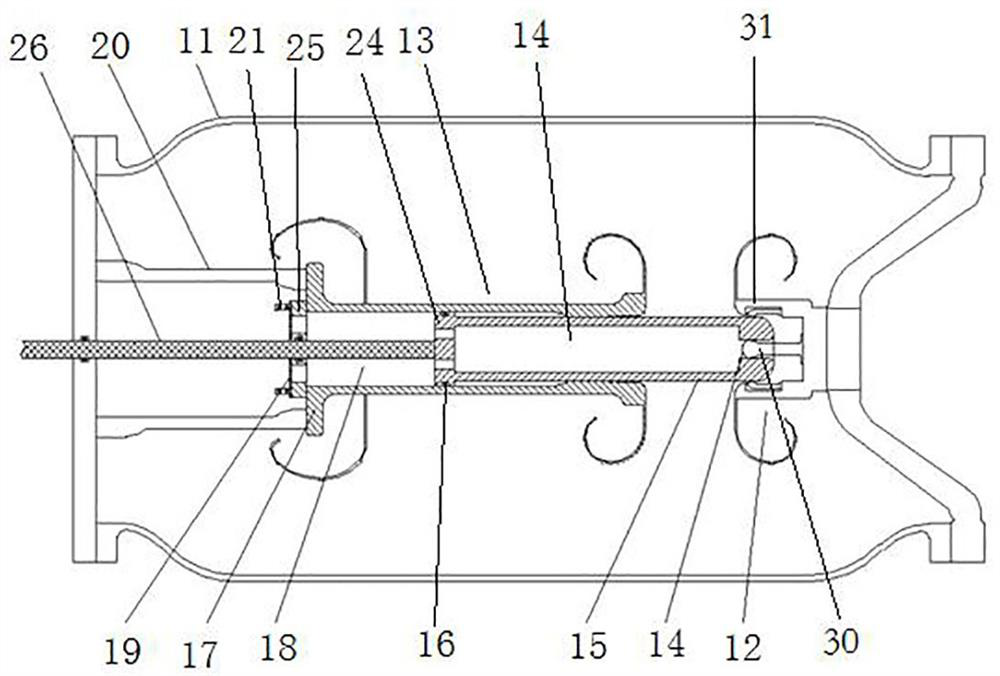

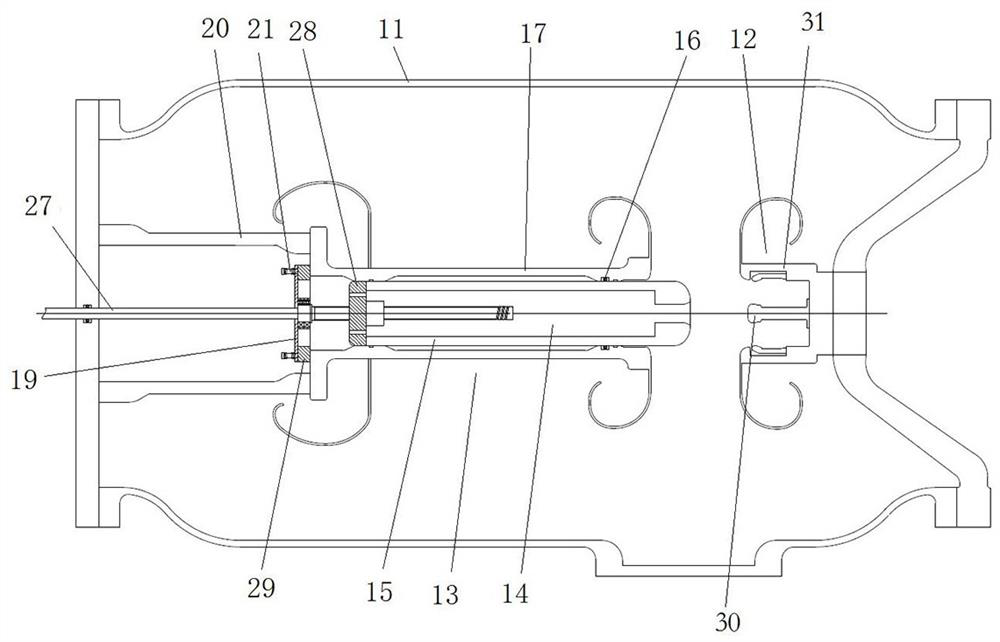

[0068] In this embodiment, the isolating switch with arc extinguishing structure is used as a bypass isolating switch for UHV series compensation, such as figure 1 As shown, the isolating switch with arc extinguishing structure includes a housing 11, a transmission mechanism, a moving contact assembly 13 arranged in the housing 11, and a static end assembly 12 located in front of the moving direction of the moving contact assembly 13, and the moving contact assembly The front of the moving direction of 13 is the direction in which the moving contact assembly 13 faces the static end assembly 12 .

[0069] In this example, if figure 1 As shown, the moving contact assembly 13 includes a moving end support 17 with a guide hole 18 and a moving contact 15, an insulating support seat 20 is provided between the rear end of the moving end support 17 and the housing 11, and the moving end support 17 is fixed on the housing 11 through an insulating support base 20 . The rear end of the...

Embodiment 2

[0079] The difference between this embodiment and Embodiment 1 is that in this embodiment, the guide hole section is a blind hole, and the bottom of the blind hole forms a plugging structure.

Embodiment 3

[0081] The difference between this embodiment and Embodiment 1 is that in this embodiment, the baffle is provided with a pressure relief structure, the pressure relief structure includes a pressure relief hole arranged on the baffle, and the rear side of the baffle is provided with The cover is equipped with a guide post, and the rear of the cover is provided with a spring for elastically pressing the cover on the baffle. When the air pressure in the piston chamber overcomes the pressing force of the spring, the cover and the discharge A gap is created between the pressure holes, through which the piston chamber is depressurized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com