Closed centrifugal pump channel impeller for liquids with abrasive or aggressive mixtures

An erosive, mixture technology, used in parts of pumping devices for elastic fluids, pumps for special fluids, non-variable-capacity pumps, etc., can solve problems such as impeller failure, delay wear, minimize wear, The effect of reducing sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

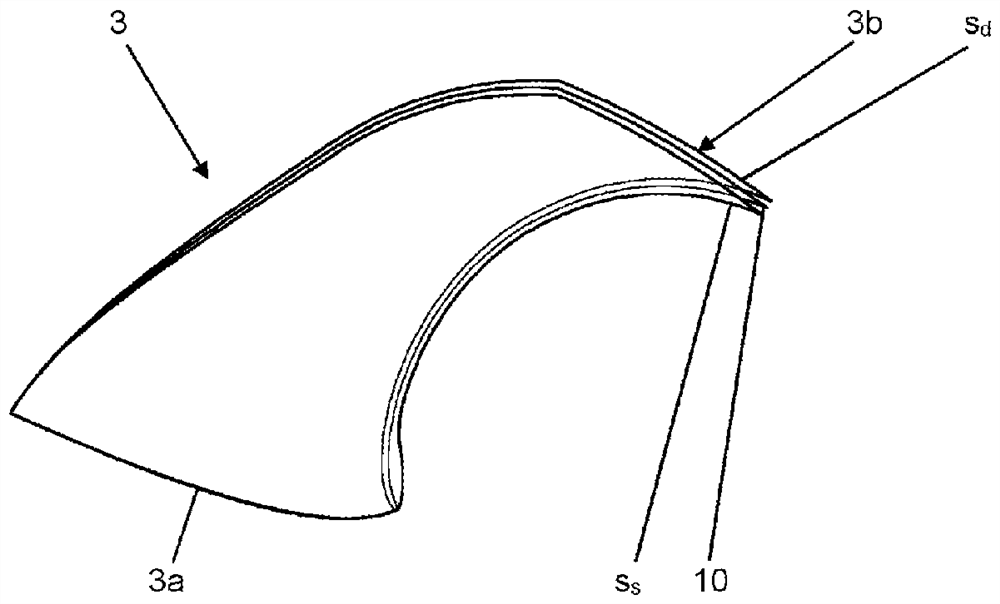

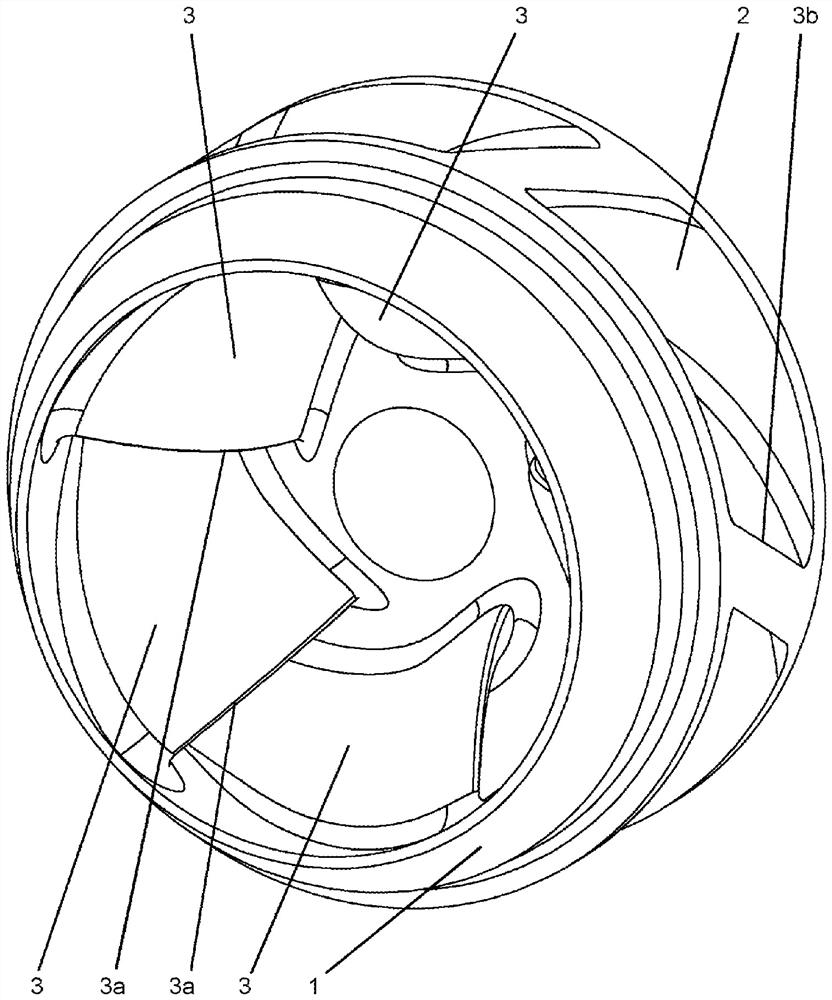

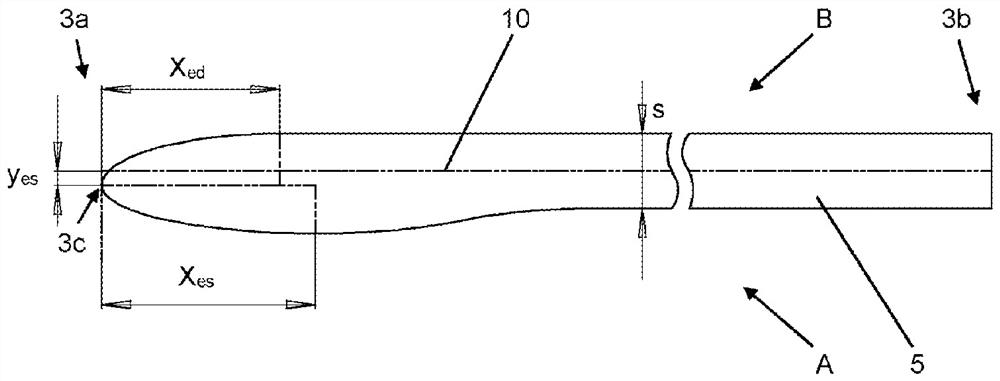

[0027] figure 1 A perspective view of a channel impeller of a centrifugal pump according to the invention is shown. The impeller is embodied as a closed channel impeller with a cover disk 1 and a carrier disk 2 . A plurality of vanes 3 extend between the carrier and cover pans. The blade 3 is delimited in the flow direction by its inlet edge (suction edge) 3 a and its outlet edge (extrusion edge) 3 b. It is delimited transversely to the direction of flow by the cover and carrier plates 1 , 2 . The channel wheel is produced from a castable or otherwise formable material, such as steel or cast mineral. The impeller can likewise be produced from a polymer with wear-resistant embedded particles, for example fine-grained silicon carbide (SiC). Impellers are mainly used for transporting liquids with abrasive or aggressive mixtures.

[0028] According to the invention, the wear resistance of the impeller and thus its achievable operating performance are optimized by means of a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com