High-precision digital printing environment-friendly ink color matching system

A technology of digital printing and color matching, applied in the direction of mixer accessories, mixers, dissolving, etc., can solve problems such as prone to abnormalities, low ink utilization rate, and poor printing quality of products, so as to improve printing quality, increase utilization rate, and reduce waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

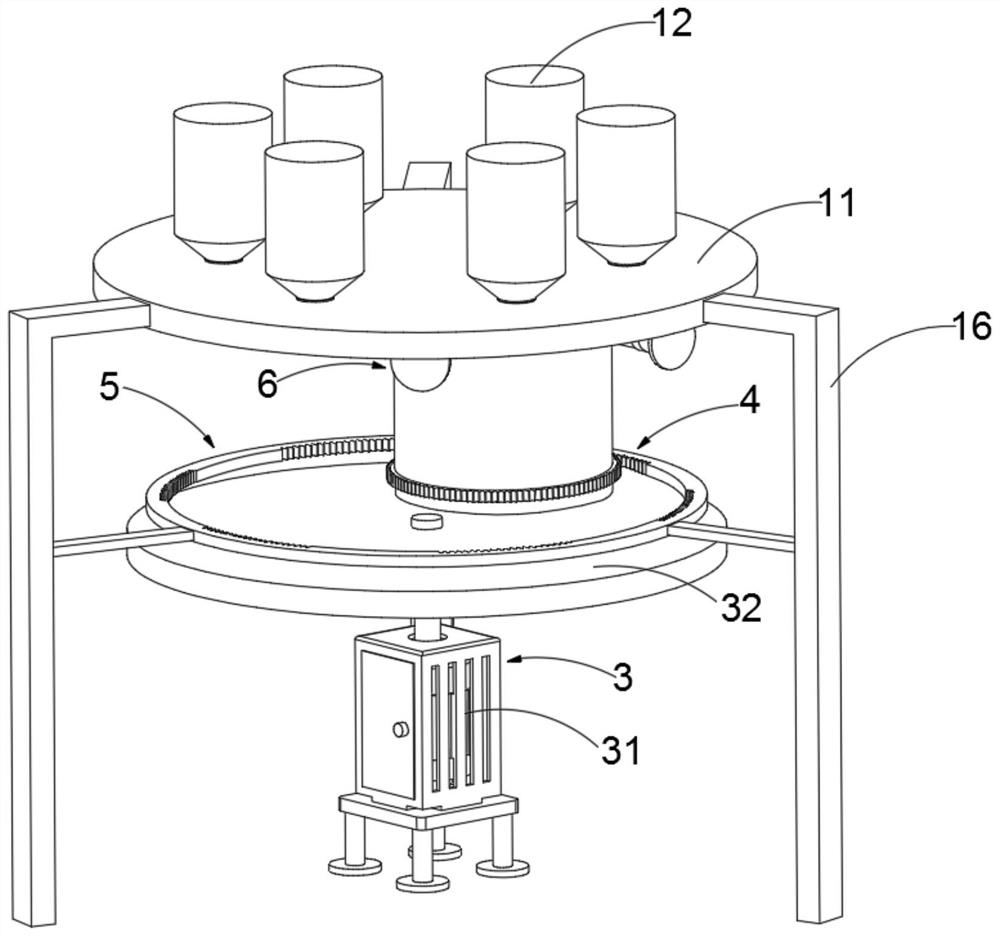

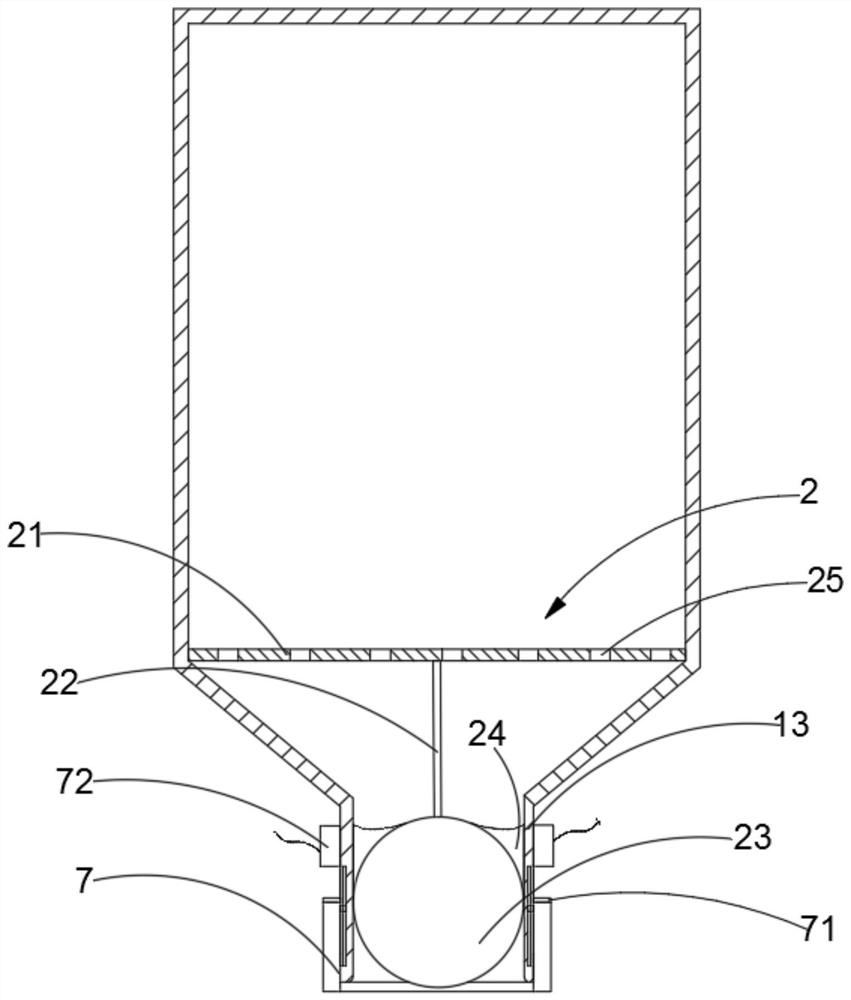

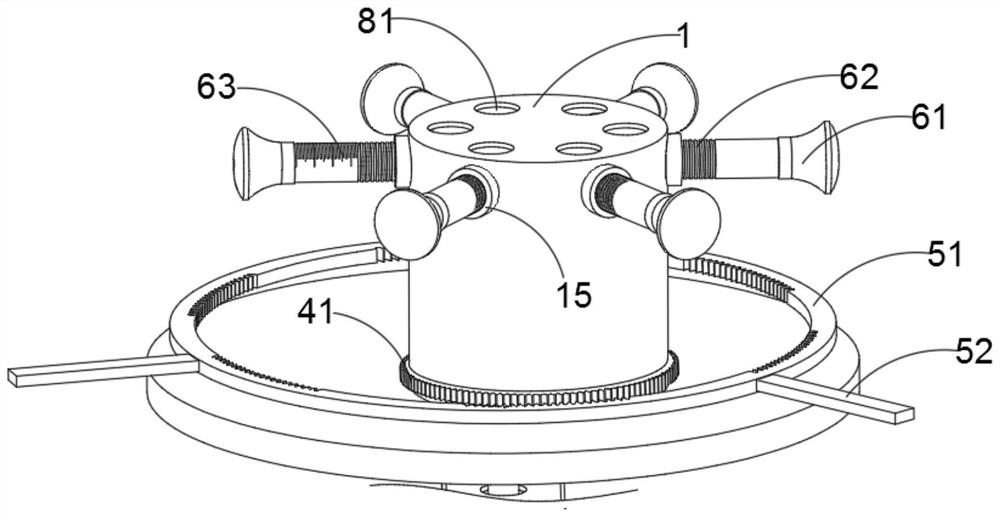

[0033] Such as Figure 1 to Figure 8 As shown, a high-precision digital printing environmentally friendly ink color matching system includes a color matching tank body 1, a fixed plate 11 is arranged above the color matching tank body 1, and several ink storage tanks 12 are arranged on the fixed plate 11 along the circumferential direction. The bottom of the storage tank 12 runs through the fixed plate 11 and is connected with a liquid outlet pipe 13. A lifting assembly 2 is arranged inside the liquid outlet pipe 13. A rotating a...

Embodiment 2

[0044] Such as Figure 4 As shown, the parts that are the same as or corresponding to those in Embodiment 1 adopt the reference numerals corresponding to Embodiment 1. For the sake of simplicity, only the differences between Embodiment 1 and Embodiment 1 are described below; the differences between Embodiment 2 and Embodiment 1 The difference is that anti-slip lines are provided on the tail end surface of the metering rod 61 .

[0045] Here, in this embodiment, anti-slip lines are provided on the tail end surface of the metering rod 61 to prevent the operator from slipping when turning the metering rod 61 , thereby affecting the accuracy of the required amount of ink 17 and affecting the final printing quality.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com