Automatic tensioning device for spinning thread winding

An automatic tensioning device and textile thread technology, applied in the direction of transportation and packaging, thin material handling, and conveying filamentous materials, etc., can solve the problems of inconvenient adjustment and inability to meet different occasions, so as to facilitate positioning and stretching, prevent Inclined misalignment, the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments.

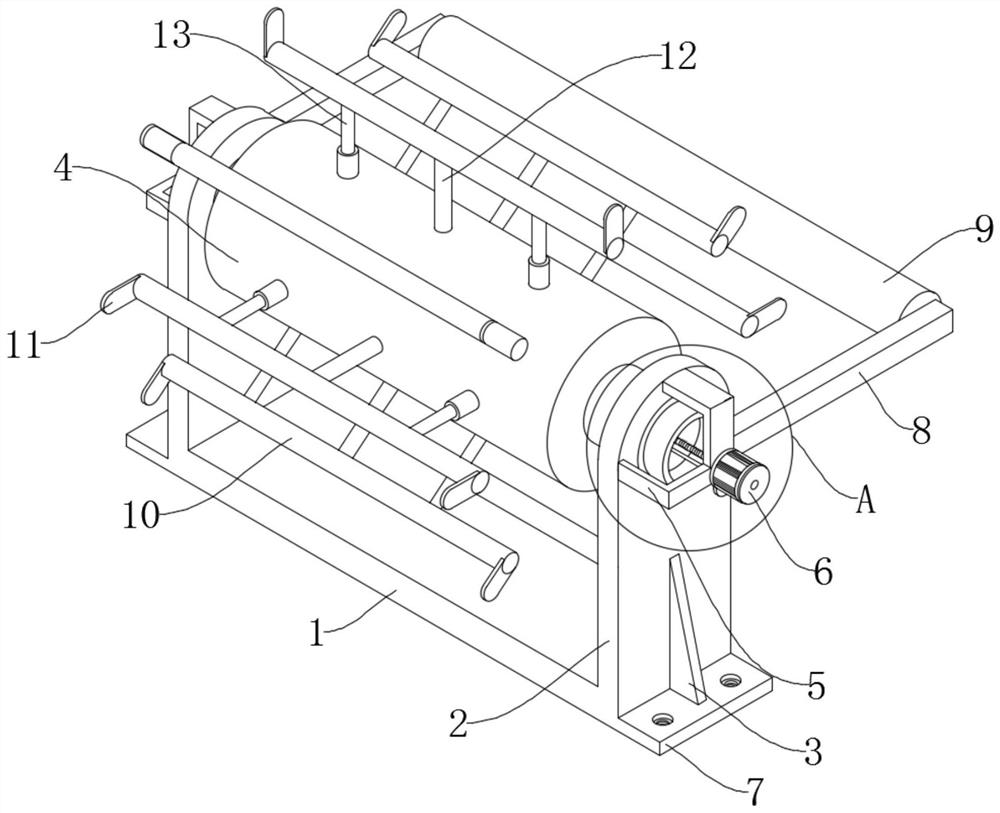

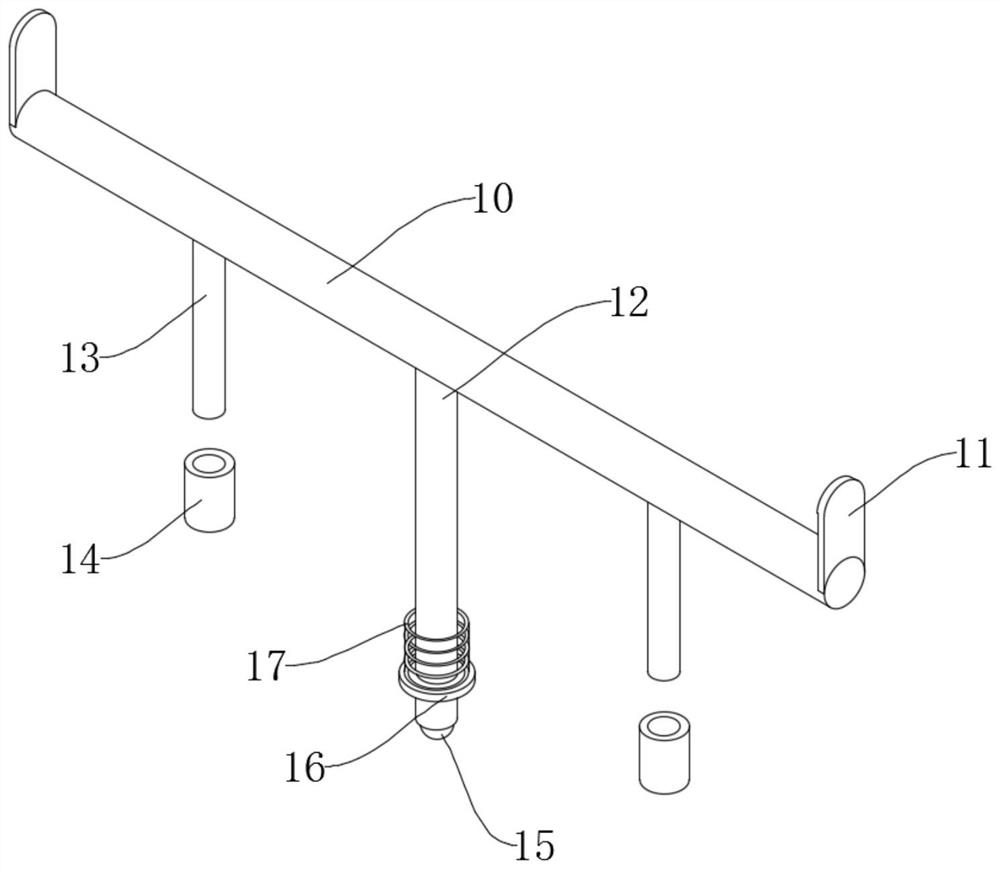

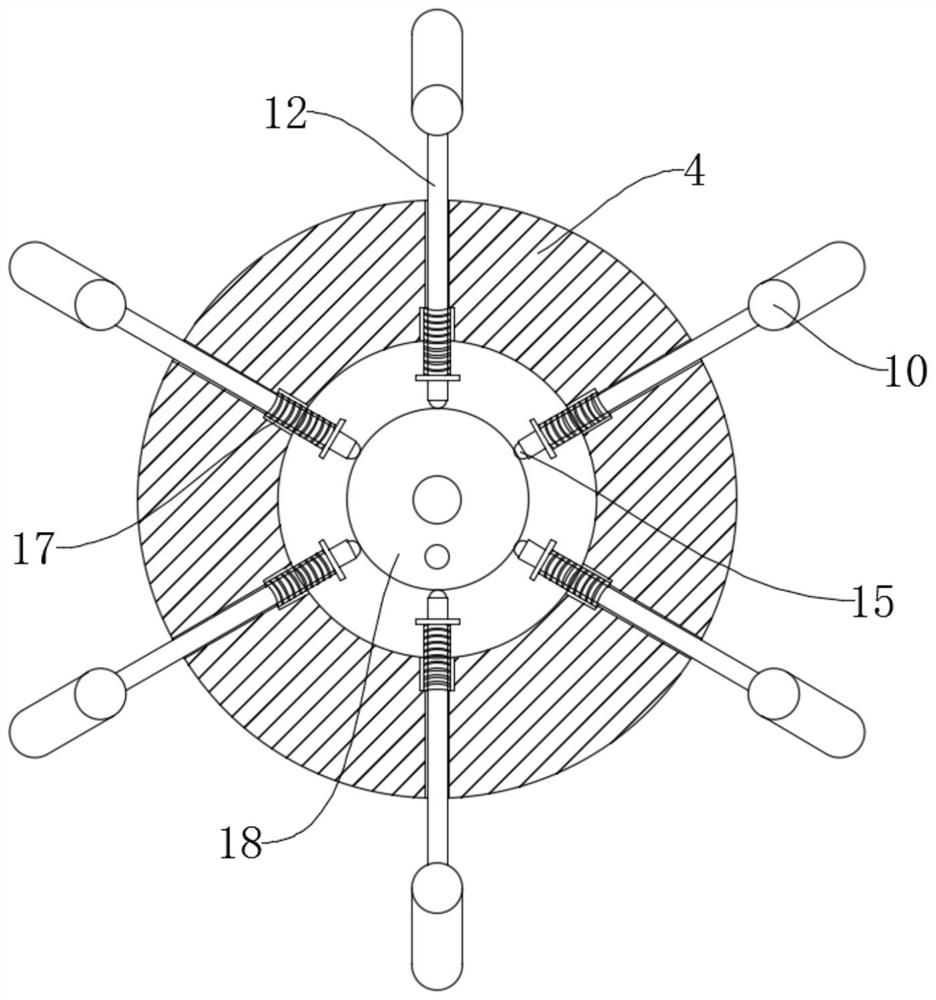

[0031] Please see attached figure 1 and attached Figure 5 , a textile thread winding automatic tensioning device, comprising a support base 1 and a fixed vertical plate member 2 installed on both sides of the top surface of the support base 1 and a winding drum 4 installed between the two fixed vertical plate members 2. , both ends of the winding drum 4 are connected with hollow drums 26, the two hollow drums 26 are respectively rotatably installed in the two fixed vertical plates 2, one of the hollow drums 26 extends to the outer wall of the fixed vertical plate 2 and A first pulley is sleeved, the adjacent side wall of the fixed vertica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com