Safe disinfection and sterilization method for food production and sterilization device thereof

A disinfection and food technology, applied in the direction of food science, etc., can solve the problems of insufficient contact of raw materials, increased energy waste, burns of staff, etc., achieve comprehensive disinfection and sterilization, improve contact comprehensiveness, and ensure disinfection and sterilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

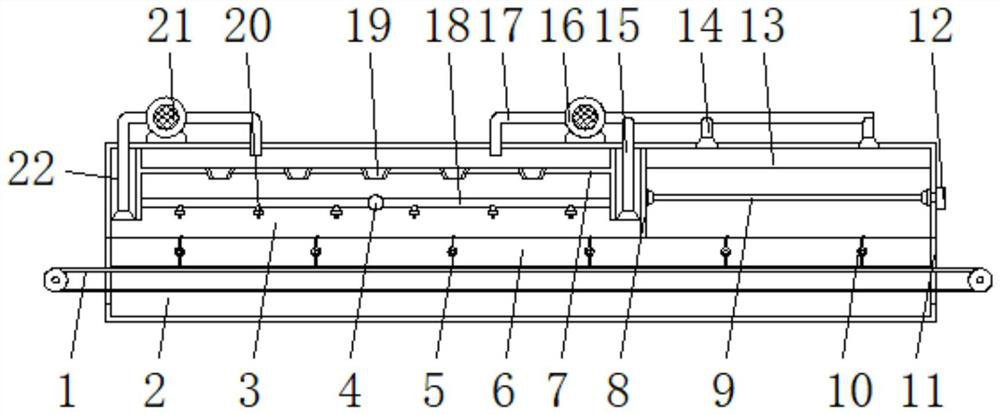

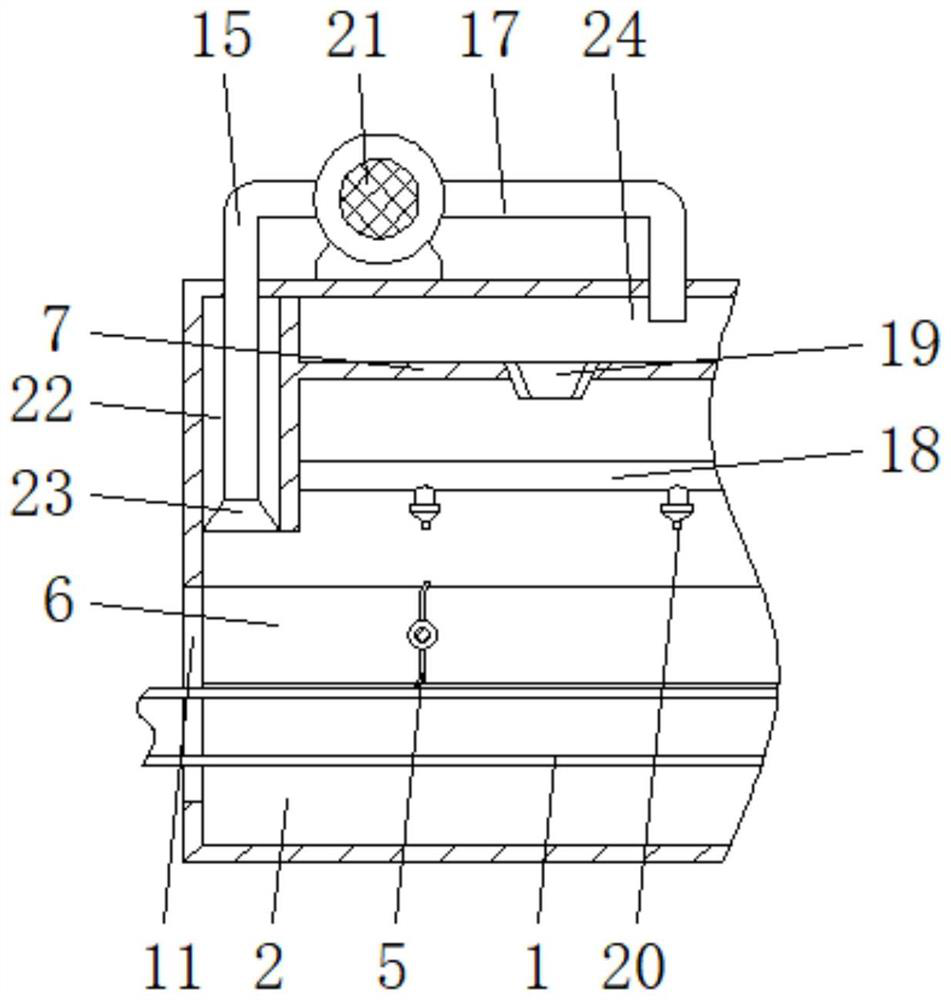

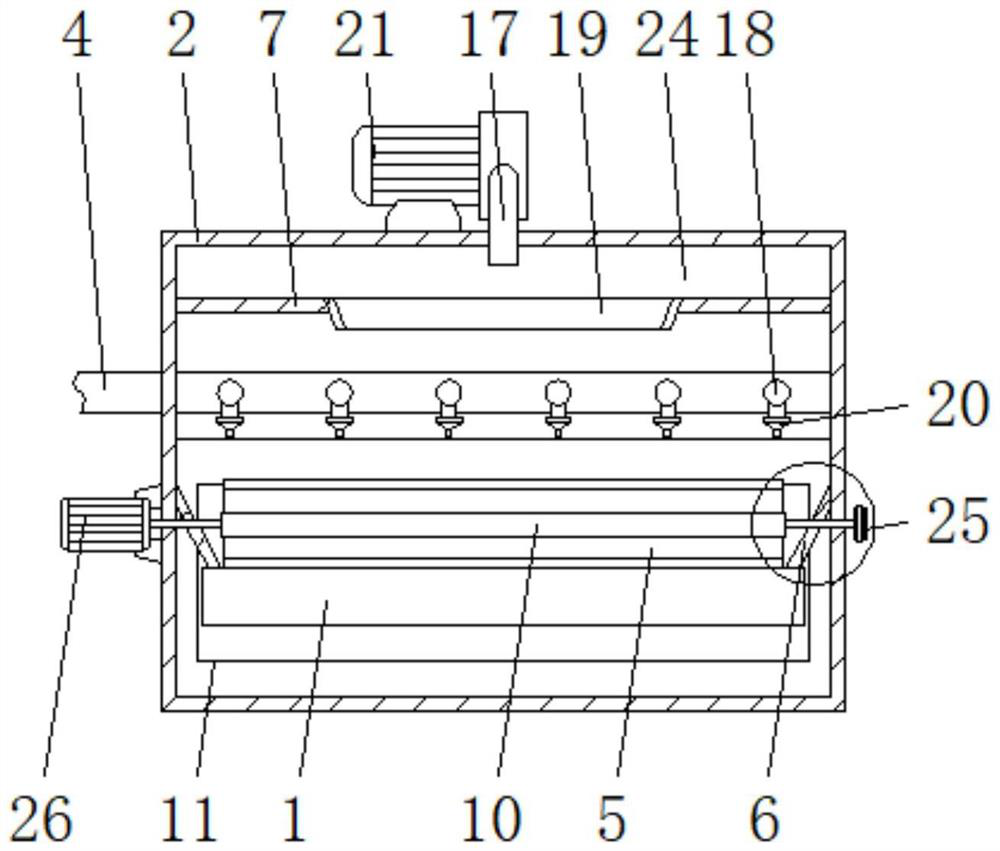

[0032] A safe disinfection and sterilization method for food production and a sterilization device thereof, comprising a conveyor belt 1, a sterilization box 2, a steam chamber 3, a top plate 7, a partition 8, an ultraviolet lamp 9, a rotating rod 10, a collection pipe 15 and a drive shaft 27, The interior of the sterilization box 2 is provided with a partition 8, and one side of the partition 8 forms a steam chamber 3 inside, and a top plate 7 is arranged inside the upper end of the steam chamber 3. The upper surface of the top plate 7 and the inner wall of the steam chamber 3 form a recovery chamber 24. Equidistantly distributed air ports 19 are provided, and the two sides of the top plate 7 form a return chamber 22. The top plate 7 is inserted with an air intake pipe 4, and the two sides of the air intake pipe 4 are inserted with distribution pipes 18 distributed equidistantly. The lower surface of the flow pipe 18 is All are embedded with nozzles 20 distributed equidistantl...

Embodiment 2

[0034] Both sides of the sterilization box 2 are provided with slots 11 inside, and the inside of the slot 11 is provided with a conveyor belt 1. The inner walls of both sides of the sterilization box 2 are symmetrically welded with a limiting plate 6, and the lower end of the limiting plate 6 is attached to both sides of the upper surface of the conveyor belt 1. close, and the distance between the lower ends of the limiting plates 6 is less than the width of the conveyor belt 1. The limiting plate 6 can block the food raw materials conveyed on the surface of the conveyor belt 1 to prevent the food raw materials from falling from the surface of the conveyor belt 1 .

[0035] On the top of the conveyor belt 1, there are equidistantly distributed rotating rollers 10. The surface of the rotating rollers 10 is welded with symmetrically distributed flaps 5, and the inside of the rotating rollers 10 is inserted with a transmission shaft that penetrates through the limit plate 6 and t...

Embodiment 3

[0037] A first air pump 16 and a second air pump 21 are installed on one side of the upper surface of the sterilization box 2, and both ends of the first air pump 16 and the second air pump 21 are connected with a collection pipe 15 and a circulation pipe 17, and the collection pipe 15 is inserted into the backflow Inside the warehouse 22, the lower end of the collection pipe 15 is provided with an air collecting cover 23 that fits with the bottom end of the return warehouse 22, and the circulation pipe 17 is inserted into the interior of the recovery warehouse 24, and the first air pump 16 and the second air pump 21 are running, which can Negative pressure is generated, and the high-temperature steam overflowing from both sides of the steam chamber 3 can be sucked into the collection pipe 15 through the gas collecting hood 23, and injected into the recovery chamber 24 through the circulation pipe 17, which can effectively prevent the high-temperature steam from overflowing thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com