Preparation method of boiled bamboo shoots and boiled bamboo shoots prepared by the method

A water-boiled and fruit technology, applied in the functions of food ingredients, food ingredients containing natural extracts, food science, etc., can solve the problems such as the quality decline of bamboo shoots, difficulty in preserving the fragrance of bamboo shoots, and microbial contamination, and avoid irritating and sour tastes. , good taste, ensure the effect of sterilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

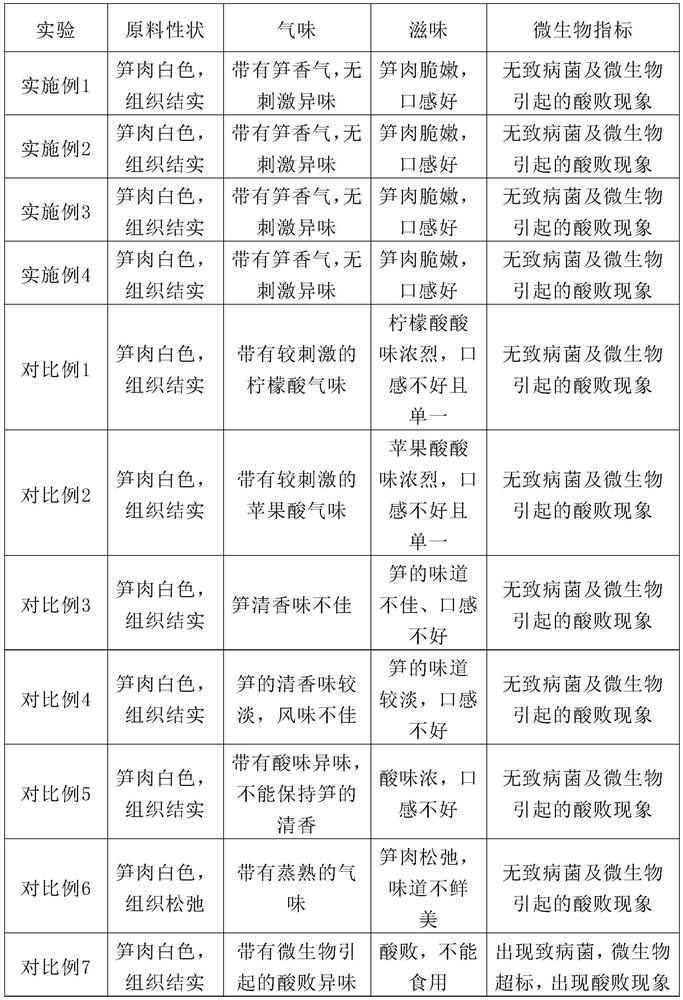

Embodiment 1

[0081] The acid regulator is a mixture of licorice water extract and orange water extract, wherein the weight ratio of licorice water extract and orange water extract is 1:10.

[0082] (1) Provide fresh spring bamboo shoots of moso bamboo that are good, free of deformities, free of sand, free of diseases and insect pests, rust spots and pre-washed.

[0083] (2) Get fresh bamboo shoots, add 5 times the aqueous solution of weight containing gluconic acid and vitamin C (in the aqueous solution, the content of gluconic acid is 0.5wt%, the content of vitamins is 0.2wt%), pressure cooker is heated to 105 ℃, 45min Finally, cool to 30°C, take out the raw bamboo shoots, peel off the skins, and cut the raw bamboo shoots into bamboo shoots of uniform size and thickness with a sterile stainless steel knife.

[0084] (3) Add the acid regulator into the water, and when the pH is 6.3, stop adding the acid regulator to obtain the acid solution, add 4 times the weight of the acid solution into...

Embodiment 2

[0090] Compared with Example 1, the preparation method of boiled bamboo shoots in Example 2 differs in that in step (3) of Example 2, the acid regulator is a mixture of honeysuckle water extract and lemonade extract, wherein Honeysuckle The weight ratio of the water extract and the lemonade extract is 1:8.

Embodiment 3

[0092] Compared with Example 1, the preparation method of boiled bamboo shoots in Example 3 differs in that in the step (3) of Example 3, the acid-adjusting agent used is a mixture of dandelion water extract and yellow peach water extract, Wherein, the weight ratio of the water extract of dandelion and the water extract of yellow peach is 1:12.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com