Outer conductor slotting device and slotting method of leaky coaxial cable

A technology of leaky coaxial cable and slotting method, applied in the direction of stripping device, metal processing equipment, manufacturing tools, etc., can solve the problems of leaky coaxial cable, low production efficiency, high mold cost, etc., achieve less debugging personnel, improve cutting effect, the effect of low slotting defect rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

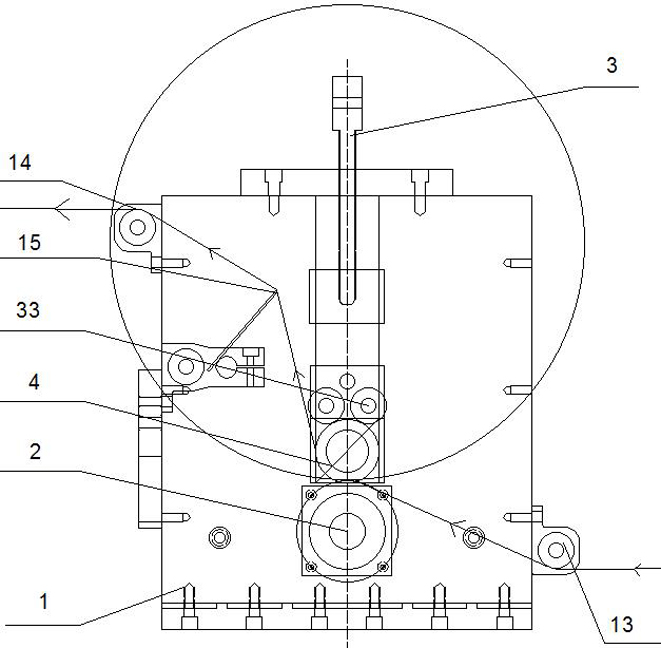

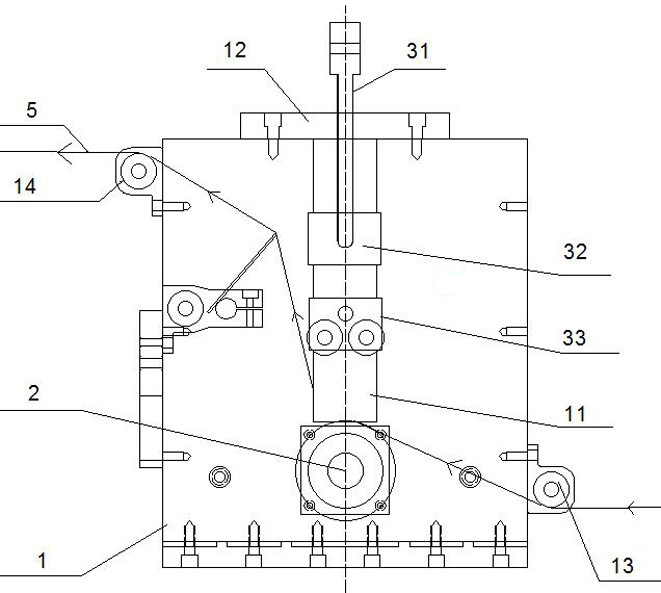

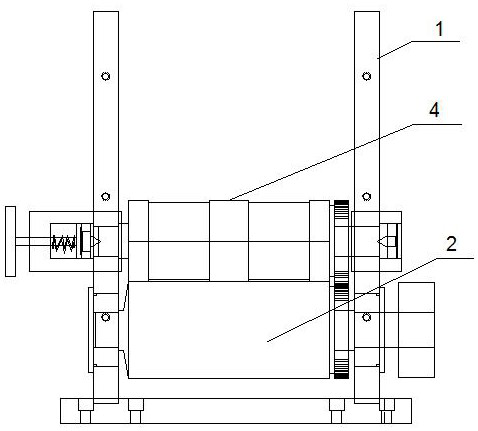

[0037] The invention provides a slotting device and a slotting method for an outer conductor of a leaky coaxial cable, such as Figure 1 to Figure 5 shown.

[0038] A slotting device for an outer conductor of a leaky coaxial cable, comprising a station frame 1, a bottom roller 2 installed on the station frame 1, a knife roller 4, and a pressing device 3, and on both side walls of the station frame 1 Correspondingly, there is a vertically arranged chute 11;

[0039] The pressurizing device 3 comprises a pressurizing rod 31 arranged from top to bottom, a pressurizing slider 32 and a pressurizing wheel 33. The outer end surface of the pressurizing rod 31 is provided with a vertically arranged external thread and passe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com