Wrap angle taking and placing device for packaging

An angle wrapping and angle wrapping technology is applied in the field of pick-and-place wrapping angle devices, which can solve the problems of poor applicability and reliability, influence of product packaging, poor applicability, etc., and achieve the effects of improving applicability, reliability and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples, but the protection scope of the present invention is not limited to the following specific examples.

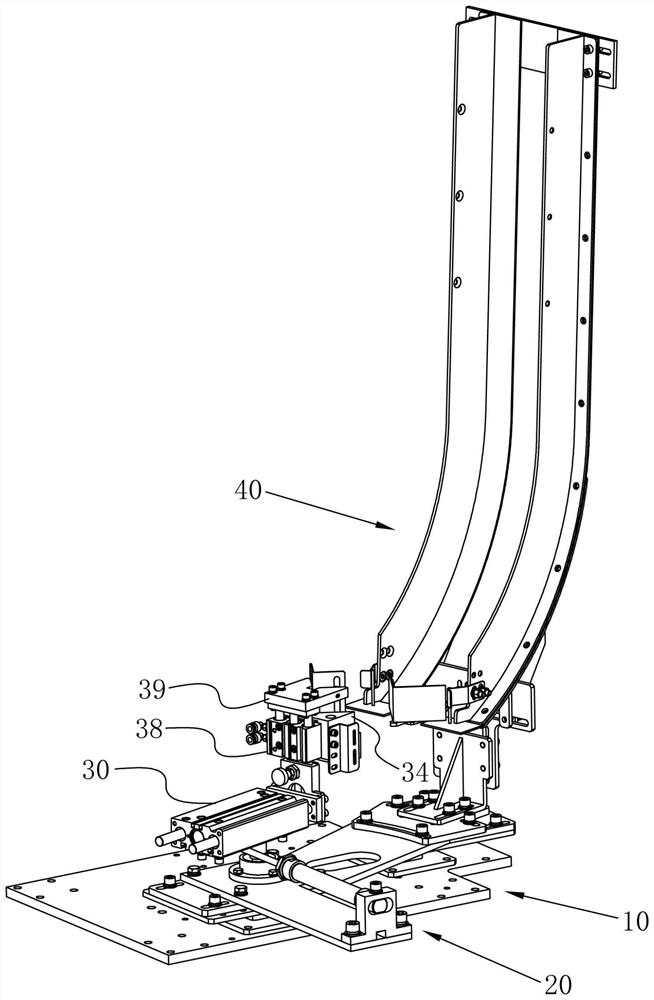

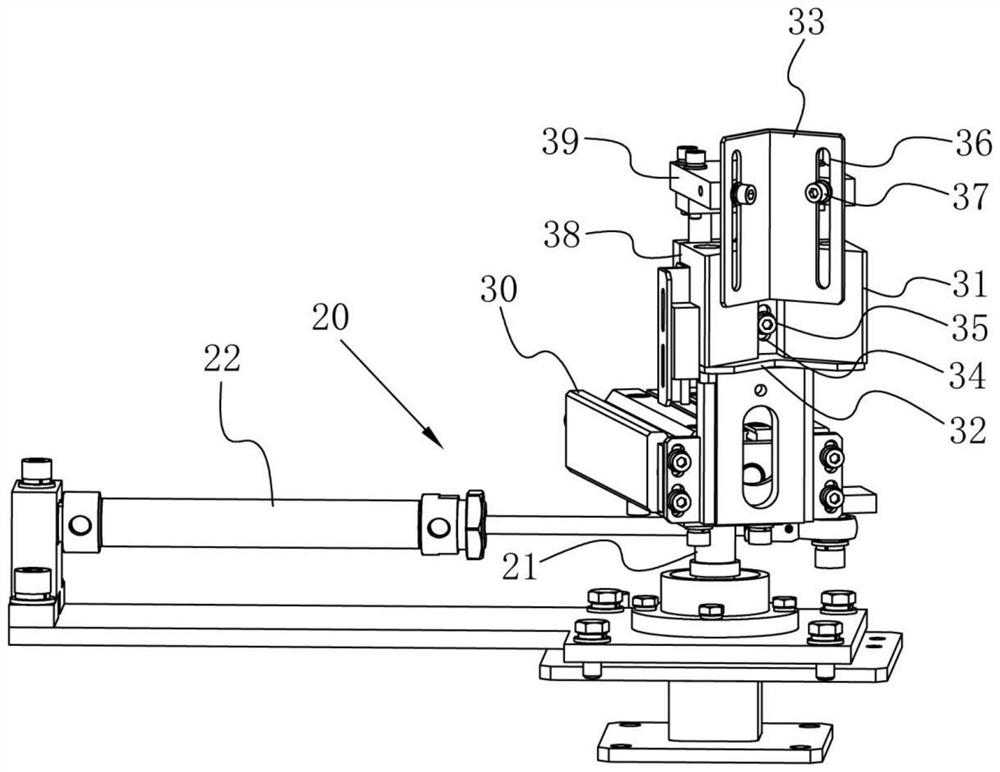

[0030] refer to figure 1 , a pick-and-place wrapping device for packaging, including a base 10, a rotating mechanism 20, a pick-and-place driver 30, a wrapping bin 40, a wrapping limit block 31, a first included angle plate 32 and a second included angle plate 33. Both the rotating mechanism 20 and the corner wrapping bin 40 are installed on the base 10 , and the pick-and-place driving part 30 is installed on the rotating mechanism 20 and the rotating mechanism 20 drives the picking-and-place driving part 30 to rotate.

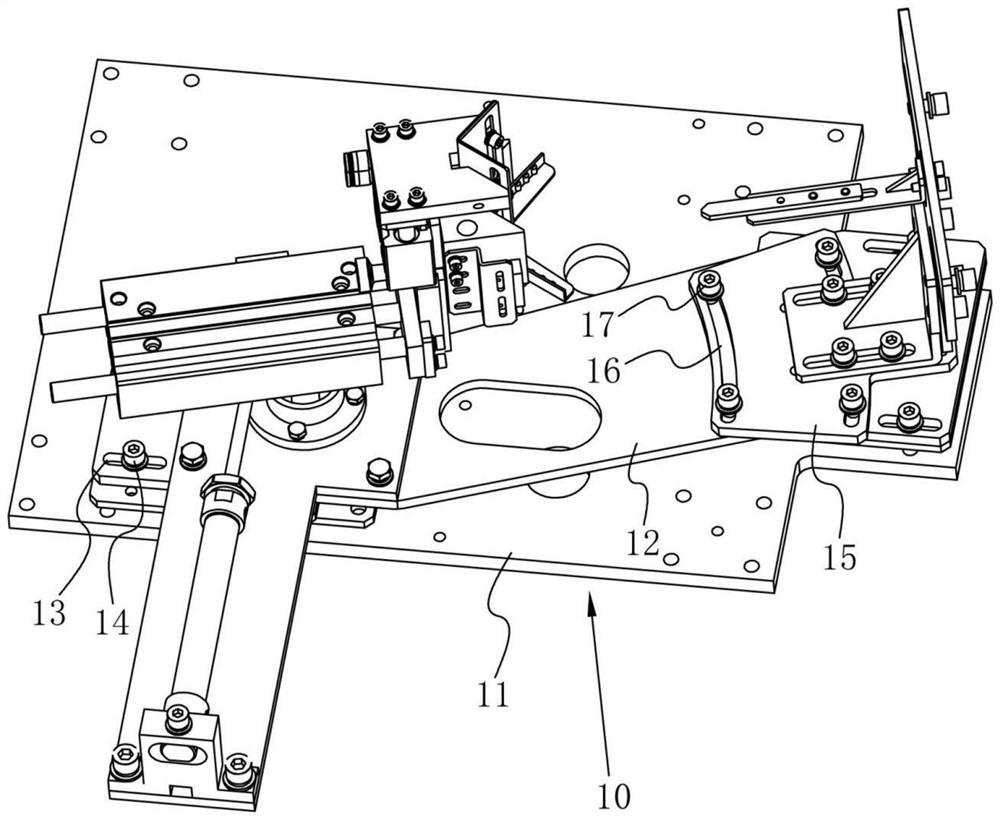

[0031] refer to figure 2 , the base 10 includes a fixed frame 11, a translation adjustment frame 12 and an angle adjustment frame 15, the translation adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com