Main arch supporting device for hoisting large-span steel structure roof

A technology of supporting device and steel structure, applied in building construction, building material processing, construction and other directions, can solve the problems of increasing the amount of tire frame, increasing the construction cost, slow construction progress, etc., to improve the installation efficiency and installation accuracy, Easy to install quickly and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

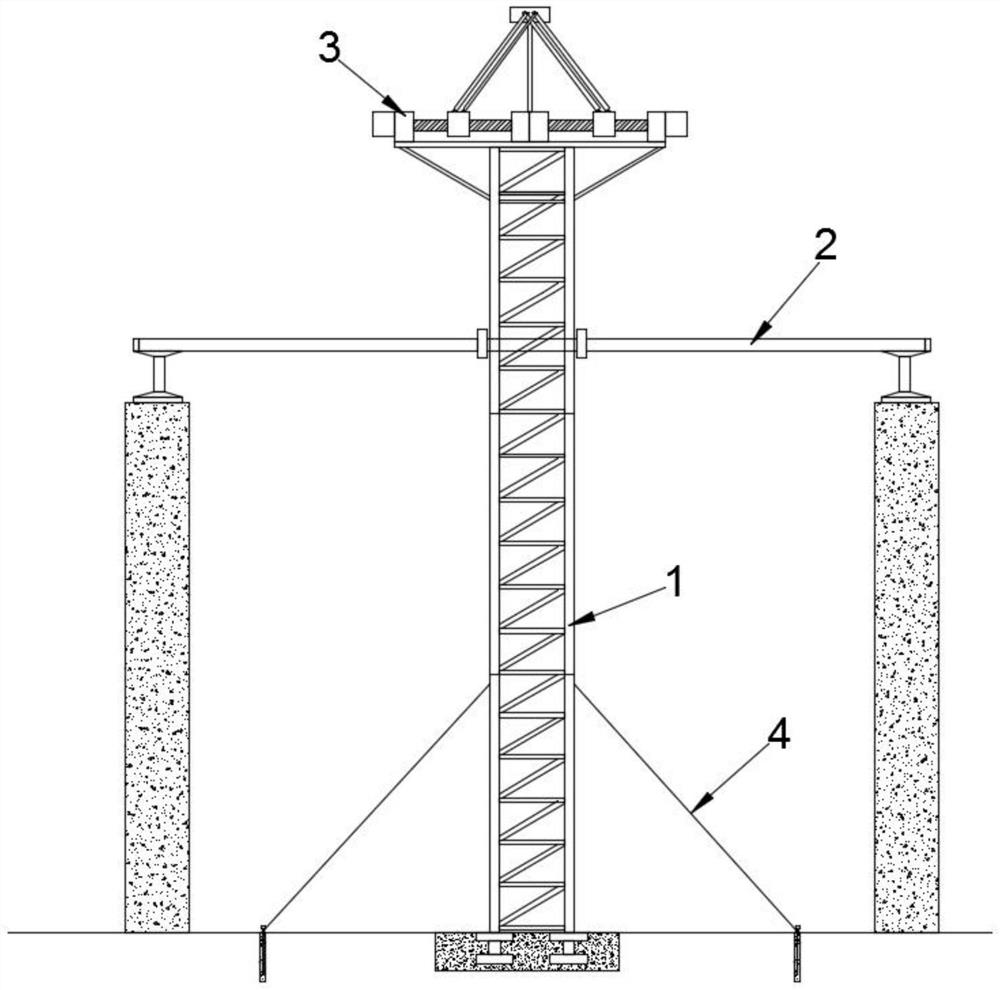

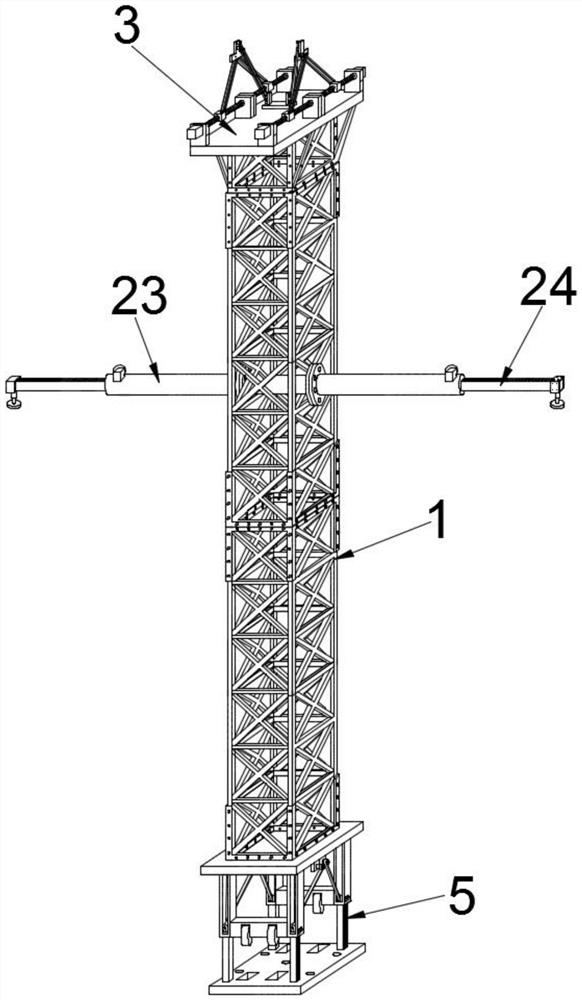

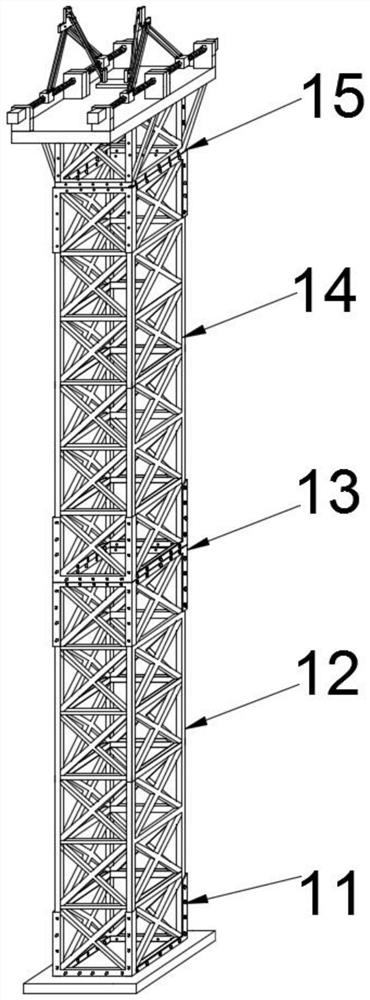

[0042] Embodiment 1: with reference to attached Figure 1-15 A main arch support device for the hoisting of a large-span steel structure roof is shown, including a steel arch support frame 1 and a horizontal auxiliary frame 2;

[0043] The steel arch support frame 1 is vertically installed between the two side walls, including a base 11, a bottom support 12, several standard supports 14 and a top support 15, and the lower end of the base 11 is provided with a The mobile mechanism 5, and in order to fix the device, the mobile mechanism 5 is installed on the bottom load-bearing support between the two side walls through the connecting bolt, the bottom support 12 is installed on the upper side of the base 11, and the bottom support 12. The standard support 14 and the top support 15 are connected by the support connector 13 and bolts to form a steel arch support frame for supporting the steel arch beam, and after installation, the position of the steel arch beam is adjusted. Fine...

Embodiment 2

[0055] Embodiment 2: Different from Embodiment 1, in order to facilitate the installation of the steel arch, the device is used to fine-tune the steel arch to facilitate installation and docking. The support mechanism 3 includes four degrees of freedom An adjustment unit and a load unit, the four-degree-of-freedom adjustment unit is symmetrically arranged, and the load-bearing unit is arranged between two symmetrically arranged four-degree-of-freedom adjustment units to carry the load on the steel arch; the load unit includes a transfer connector 33, a first The connecting rod 34 and the load plate 35, the transfer connector 33 is a T-shaped connector arranged above the support platform 152, and first hinge supports 334 are respectively arranged on the inner and outer sides of the transfer connector 33 And the hinge rod 331, the hinge rod 331 is used in conjunction with the four-degree-of-freedom adjustment unit, the first hinge support 334 is hingedly connected to one end of t...

Embodiment 3

[0059] Embodiment 3: Different from Embodiment 1, in order to facilitate the movement of the device during use, that is, after one span is hoisted, the device can be moved to install the next span, saving disassembly and installation process to improve work efficiency, the moving mechanism 5 includes an installation connecting plate 51, a first vertical rod 52, a second vertical rod 53, a roller 55 and an adjustment assembly, and the second vertical rod 53 is arranged under the bottom steel plate 111 side, and two adjacent second poles 53 are provided with connecting crossarms 54, the rollers 55 are installed on the connecting crossarms 54, and an adjustment groove 531 is provided on the second poles 53, so The adjustment groove 531 is used in conjunction with the movable end of one end of the first vertical rod 52, and the other fixed end of the first vertical rod 52 is arranged on the installation connecting plate 51, and a bolt connection is provided on the installation conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com