Novel error-proofing rapid measuring mechanism and groove width measuring method

A measuring mechanism and fast technology, applied in the direction of measuring devices, mechanical measuring devices, mechanical devices, etc., can solve the problems of insufficient precision and large errors, and achieve the effects of high accuracy, easy operation, and reduced errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Further set forth by the following specific examples;

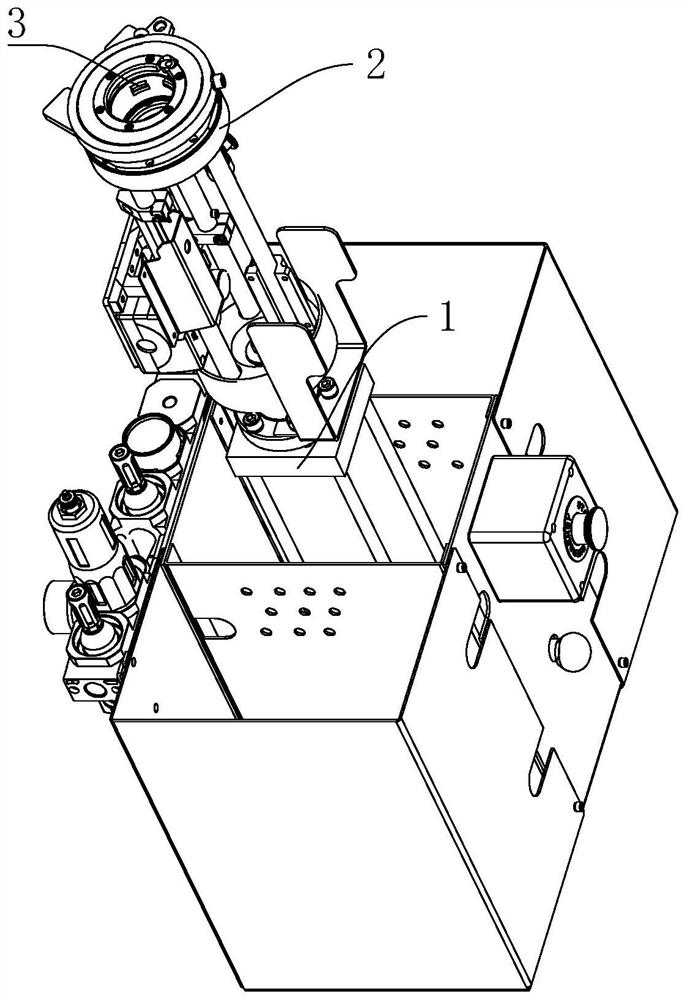

[0047] Such as figure 1 As shown, a new type of error-proof fast measuring mechanism includes a driving mechanism 1 , a measuring component 2 and a locking component 3 .

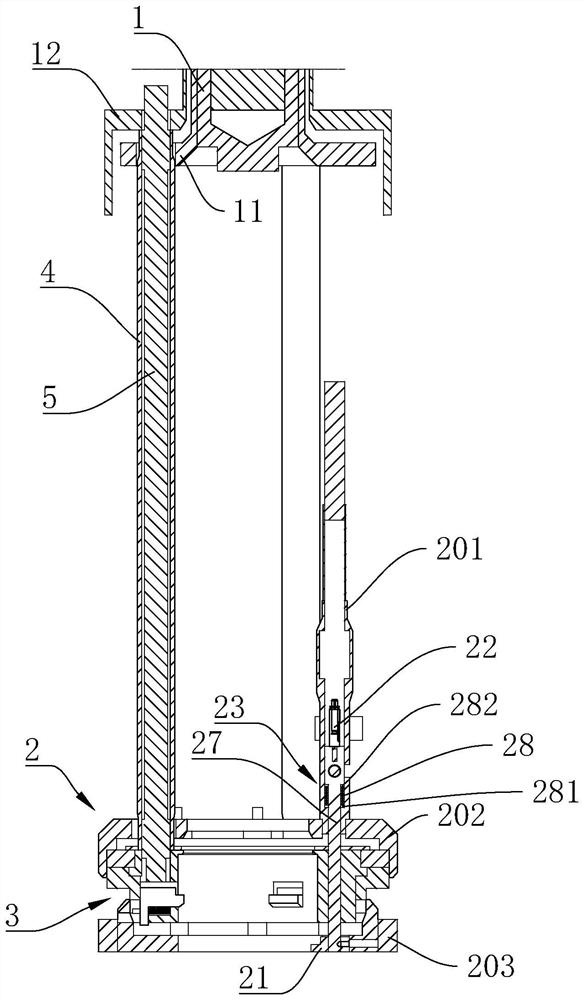

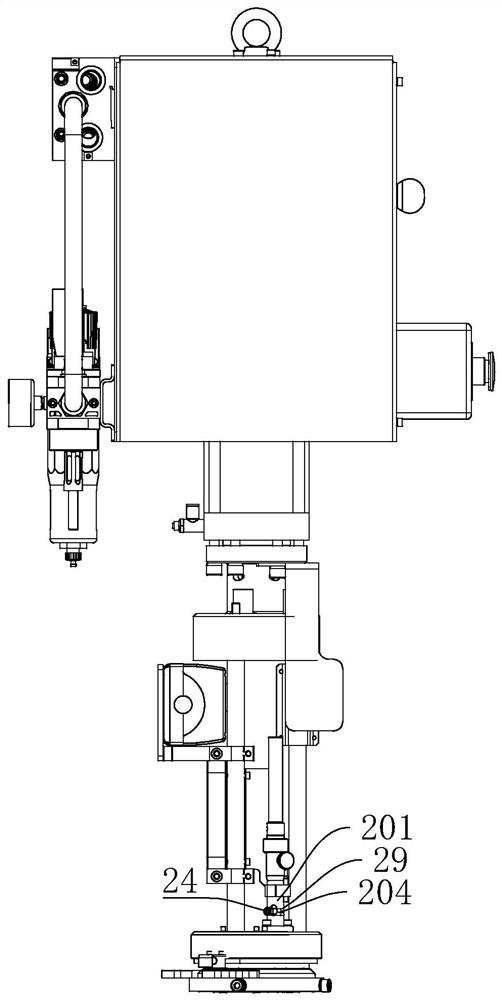

[0048] Such as figure 1 and figure 2 As shown, the linear drive mechanism 1 has a fixed end 11 and a movable end 12 capable of relative displacement with the fixed end 11 in the axial direction.

[0049] Specifically, the linear drive mechanism 1 may be an air cylinder, an oil cylinder or a gas-hydraulic booster cylinder.

[0050] Taking the gas-liquid pressurized cylinder as an example, the fixed end 11 is a cylinder body, and the movable end 12 is a piston.

[0051] The measuring assembly 2 is connected to the fixed end 11 through several sleeves 4 arranged in the axial direction, and the locking assembly 3 is connected to the movable end 12 through a central rod 5 movably sleeved in the sleeves 4 .

[0052] The measuring component 2 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com