Assembling type express intelligent sorting equipment

An assembled and intelligent technology, applied in sorting, mechanical equipment, vibration suppression adjustment, etc., can solve the problems of inconvenient replacement and maintenance of cushion pads, low sorting efficiency, affecting express delivery efficiency and user experience, etc., to reduce labor costs. investment, high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

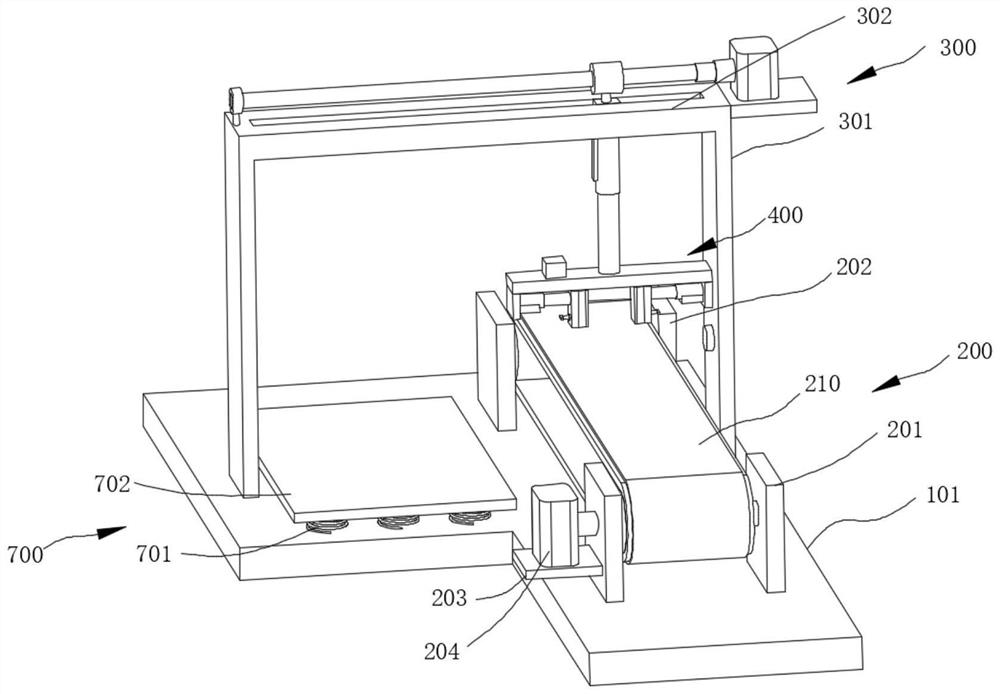

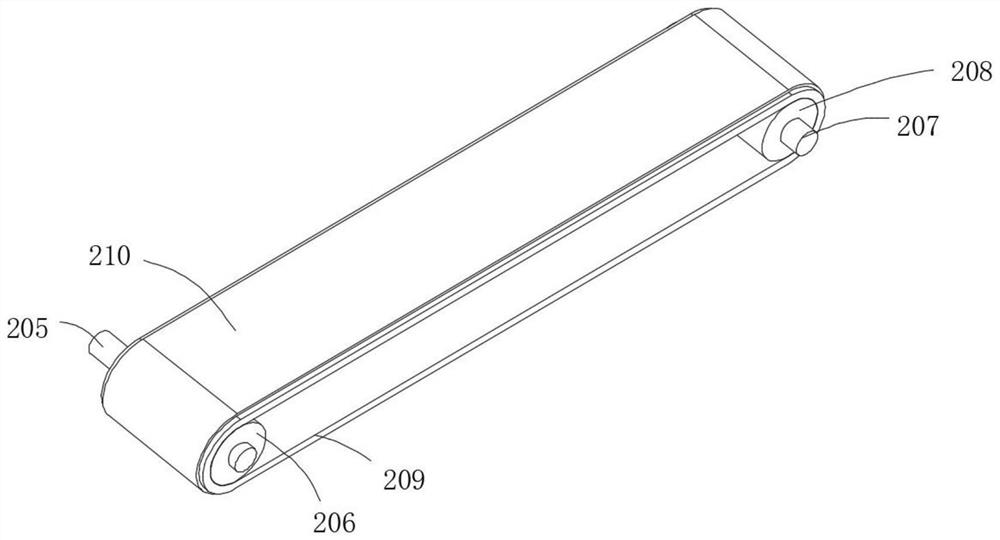

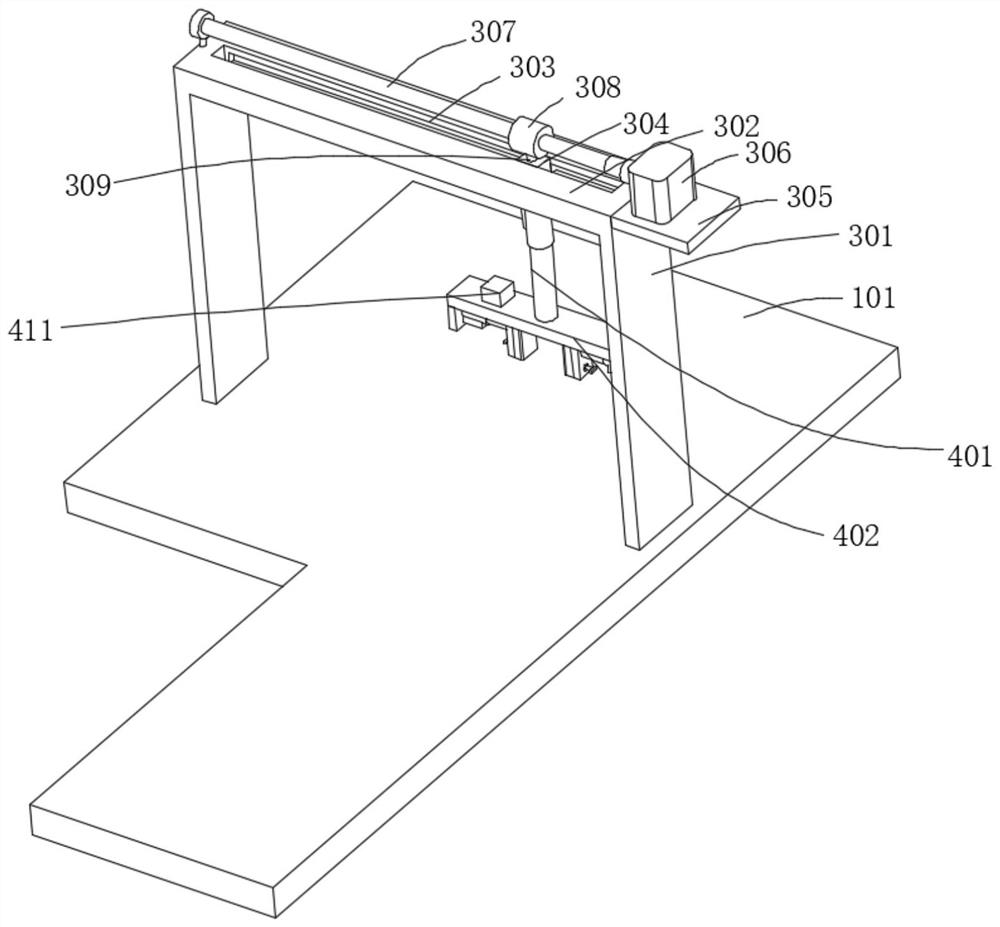

[0065] see Figure 1-4 , the present invention provides a technical solution: an assembled express intelligent sorting equipment, an equipment platform 101, a transmission mechanism 200 and a moving mechanism 300 are arranged on the equipment platform 101; the transmission mechanism 200 includes two first mounting plates 201, two A second mounting plate 202, two first mounting plates 201, and two second mounting plates 202 are symmetrically fixedly connected to the upper surface of the equipment platform 101; a first mounting plate 201 is fixedly connected to a first mounting seat on the outer wall of one side 203, a first motor 204 is installed on the upper surface of the first mounting base 203, and the output end of the first motor 204 is fixedly connected with a drive rod 205 that runs through a first mounting plate 201 and is rotatably connected with another first mounting plate 201; The driving roller 206 is installed on the outer wall of the rod 205; the driven roller 2...

Embodiment 2

[0074] see figure 1 , the present invention provides a technical solution: an assembled express intelligent sorting equipment, which also includes a buffer mechanism 700, and the buffer mechanism 700 includes a compression spring 701; the compression spring 701 is fixedly connected to the upper surface of the equipment platform 101; the compression spring 701 is far away from the equipment One end of the platform 101 is fixedly connected with a buffer plate 702 .

[0075] Specifically, please refer to Embodiment 1. When the courier moves to the designated area, the user starts the second electric telescopic rod 404 again at this time. The clamping plate 405, the auxiliary plate 406, and the buffer pad 407 shrink, and when the clamping plate 405, the auxiliary plate 406, and the buffer pad 407 are not in contact with the express, the express will fall to the designated area;

[0076] By providing the compression spring 701 and the buffer plate 702, it can be ensured that the c...

Embodiment 3

[0078] see Figure 1-9 , the present invention provides a technical solution: an assembled express intelligent sorting device, the installation mechanism 500 includes a connecting hole 501, and the connecting hole 501 is opened on the side wall of the clamping plate 405; the connecting holes 501 respectively penetrate the left side of the clamping plate 405 , the outer walls on both sides of the right side; the auxiliary plate 406 is provided with a circular connection cavity 503, and the end of the auxiliary plate 406 close to the clamping plate 405 is provided with a groove 502; the groove 502 communicates with the connection cavity 503, and the connection cavity 503 is clamped A clamping block 504 is fixed, and the clamping block 504 and the groove 502 are vertically arranged; the thickness of the clamping block 504 is adapted to the depth of the connecting cavity 503, and the diameter of the connecting cavity 503 is greater than the length of the clamping block 504; the siz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com