Main shaft capable of electromagnetically adjusting pre-tightening force of bearing

A technology for adjusting the bearing and preloading force, which is applied to the parts of grinding machine tools, metal processing equipment, manufacturing tools, etc. Stable operation, reduced noise and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

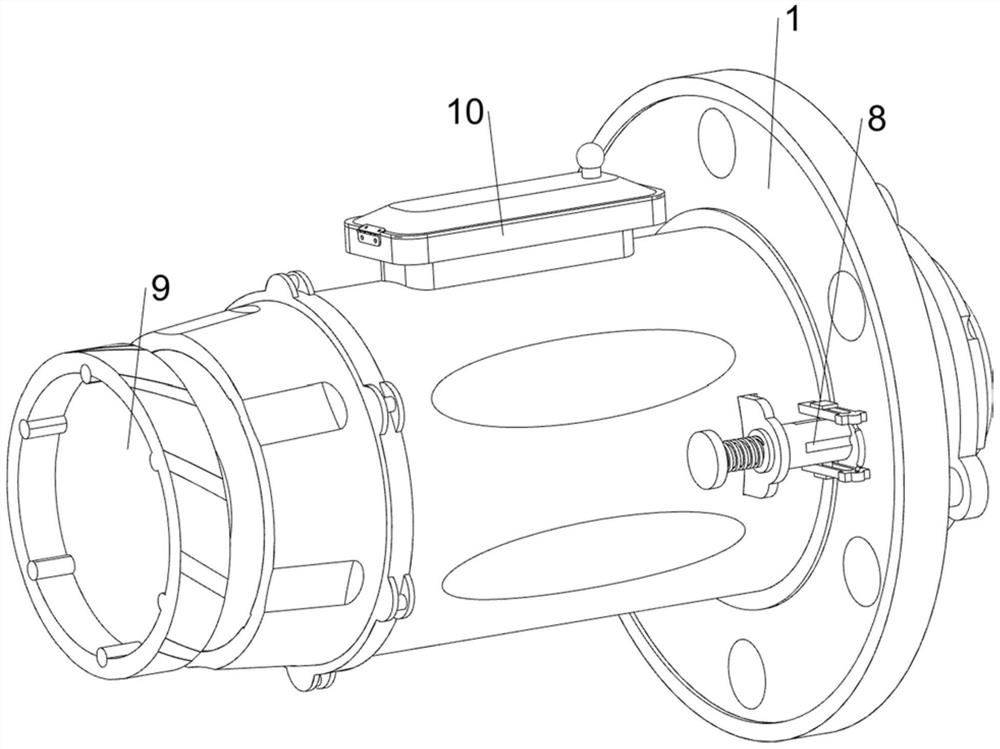

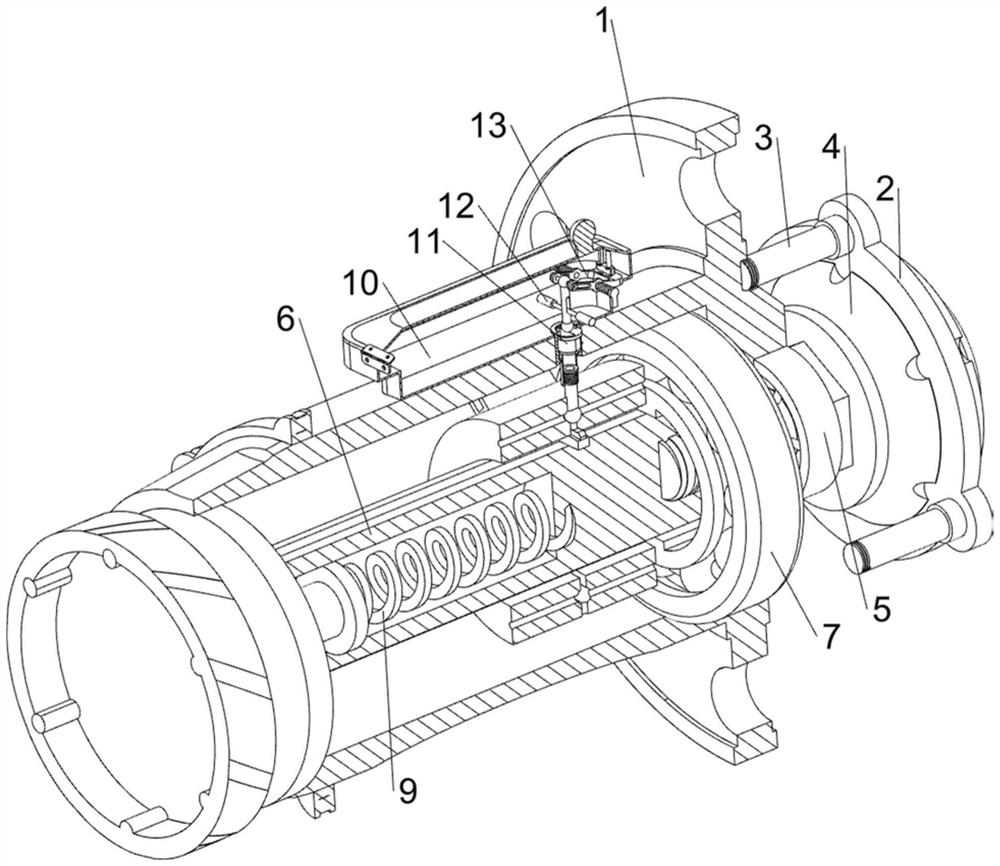

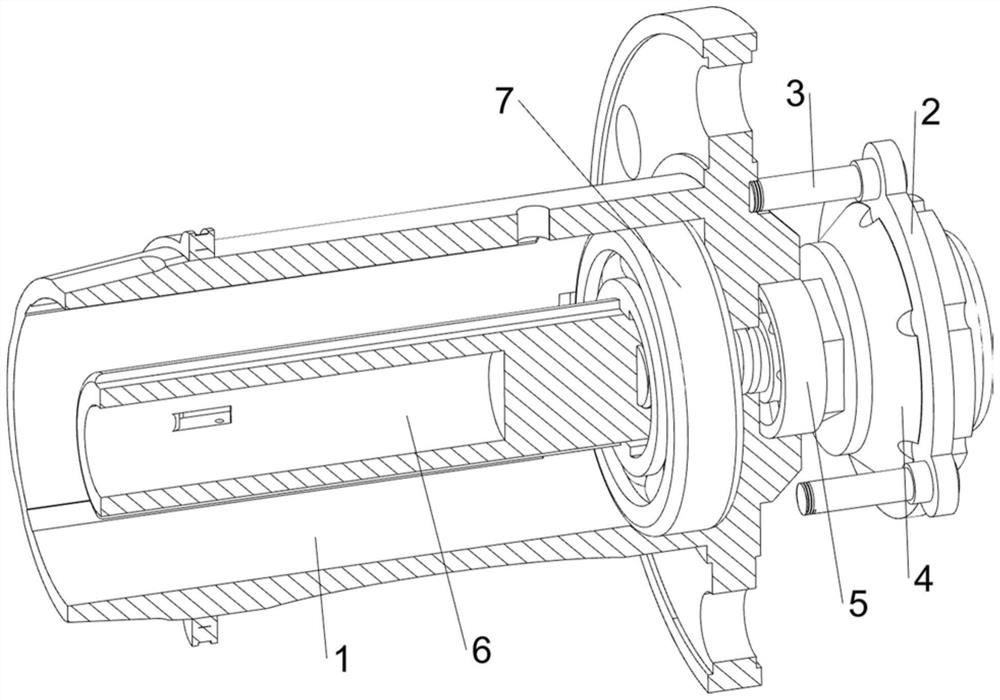

[0035] A main shaft for electromagnetically adjusting bearing pretightening force, in Figure 1-3As shown in , it includes an outer shaft 1, a first connecting block 2, a bolt 3, a servo motor 4, a threaded shaft 5, an inner shaft 6, a bearing 7, a pre-tightening mechanism 8 and a replacement mechanism 9, and the right side of the outer shaft 1 is threaded The way of connection is connected with three bolts 3 for fixing at even intervals, and the first connecting block 2 is slidingly connected between the right sides of the three bolts 3, and the servo motor 4 is installed on the first connecting block 2, and the servo motor 4 outputs A threaded shaft 5 is clamped on the shaft, and the threaded shaft 5 is slidingly connected with the right side of the outer shaft 1. The inner right side of the outer shaft 1 is slidingly connected with a bearing 7, and the inner ring of the bearing 7 is clamped with a shaft for driving the workpiece to rotate. The inner shaft 6, the right side ...

Embodiment 2

[0040] On the basis of Example 1, in figure 1 , figure 2 , Figure 7 with Figure 8 Shown in, also includes lubricating mechanism 10, and lubricating mechanism 10 includes material discharging frame 100, protective cover 101, hinge 102, annular shaft 103, rotating block 104, unloading pipe 105, lifting pipe 106, connecting pipe 107 and Return spring 108, the top right side of the outer shaft 1 is provided with a discharge frame 100 for storing lubricating oil, the left side of the discharge frame 100 is connected with a dustproof protective cover 101 through a hinge 102, the hinge 102 can rotate automatically, and the protective cover 101 is a transparent material, which is convenient to check the remaining amount of lubricating oil inside the discharge frame 100. The protective cover 101 is in contact with the top of the discharge frame 100. The inner right side of the outer shaft 1 is slidingly provided with an annular shaft 103. The inside of the annular shaft 103 is ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com