Large and small rare metal ore separation equipment

A technology for separating equipment and rare metals, which is applied in the directions of cleaning methods, cleaning methods and utensils, chemical instruments and methods using liquids, etc., which can solve the problems of low work efficiency, consumption, and time-consuming, and achieve good results and good separation effects. , to prevent the effect of incomplete collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

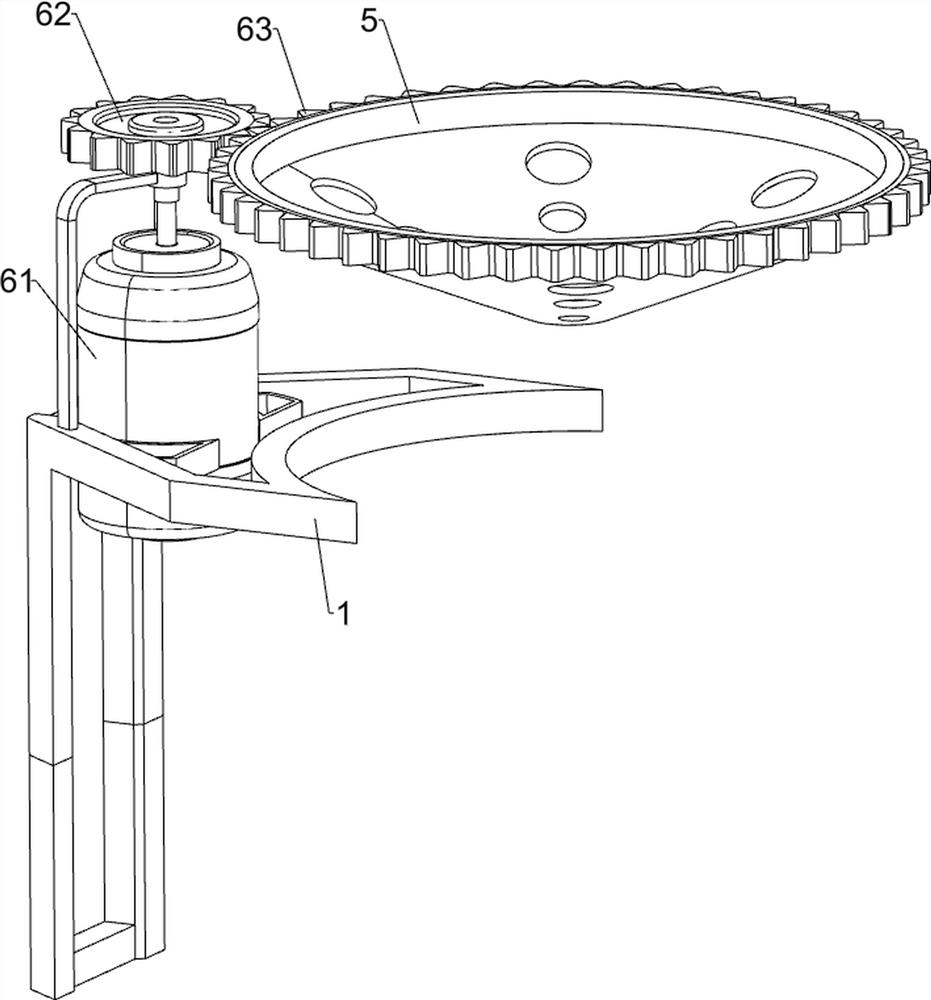

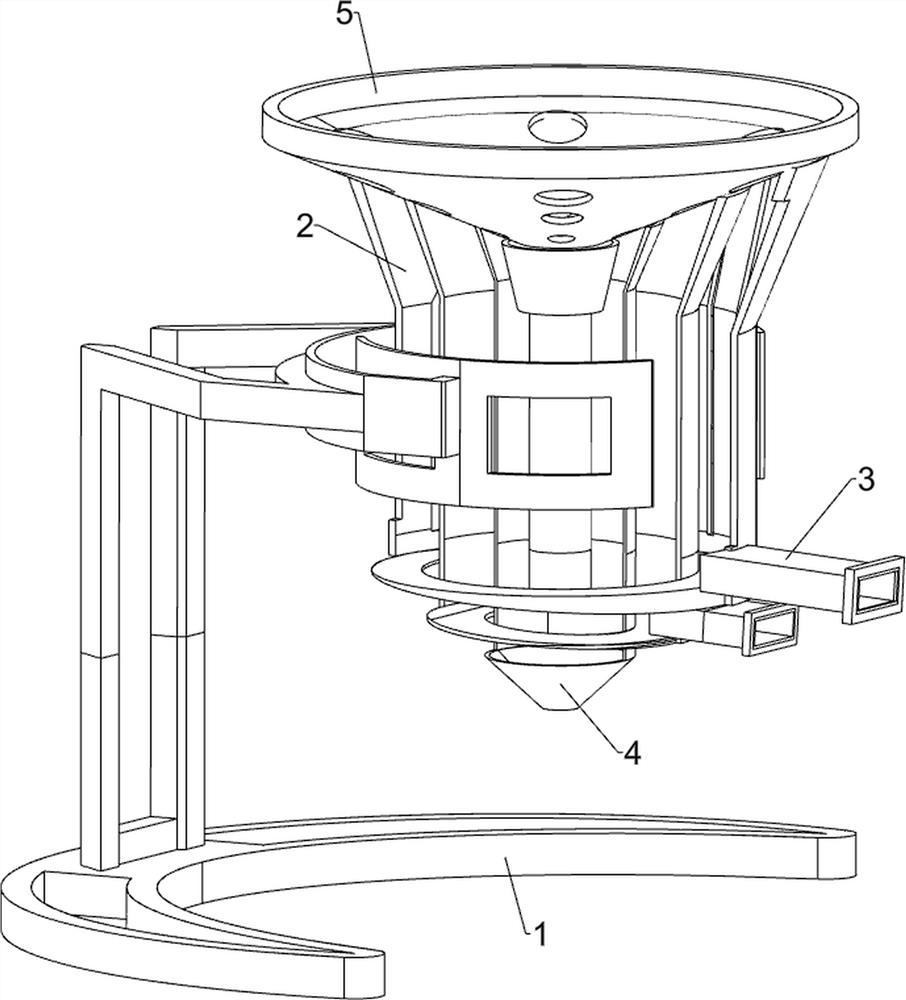

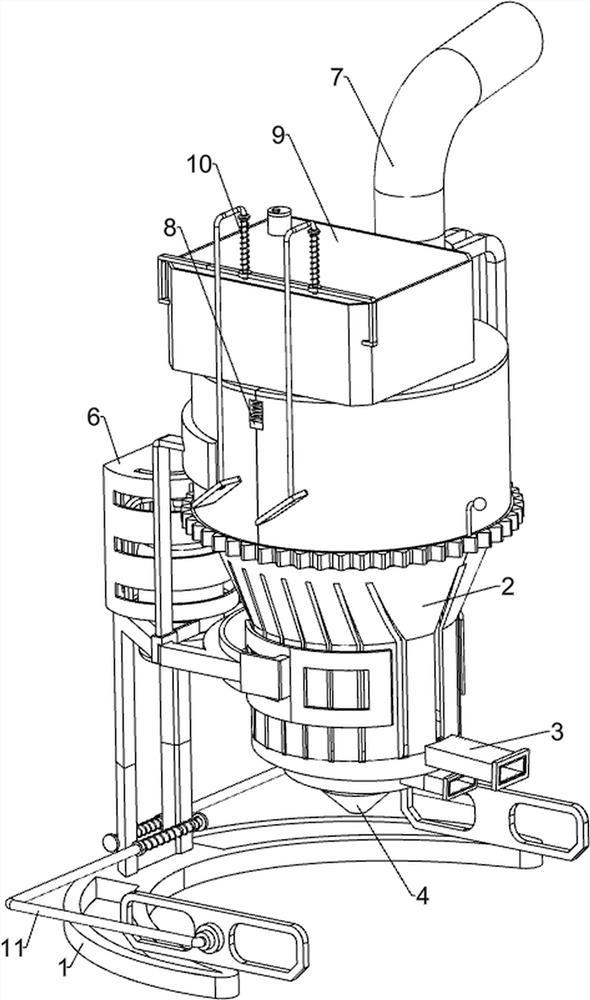

[0029] A rare metal ore size separation equipment, such as Figure 1-5 As shown, it includes a mounting frame 1, a distribution frame 2, a discharge pipe 3, a discharge pipe 4, a conical distribution plate 5, a drive assembly 6 and a guide assembly 7, and the upper side of the installation frame 1 is connected with a distribution frame 2. There are two upper and lower discharge pipes 3 connected to the lower side of the right part of the material distribution frame 2, the lower side of the material distribution frame 2 is connected to the lower material pipe 4, and the upper side of the material distribution frame 2 is rotated to provide a conical distribution plate 5. A drive assembly 6 is provided between the installation frame 1 and the conical distribution tray 5, and a guide assembly 7 is provided on the upper side of the installation frame 1.

[0030] When the rare metal ore needs to be separated in size, the rare metal ore is poured into the guide assembly 7, and the ra...

Embodiment 2

[0036] On the basis of Example 1, such as figure 2 , Figure 6 , Figure 7 , Figure 8 and Figure 9 As shown, it also includes a blanking assembly 8, the blanking assembly 8 includes a vibrating plate 83, a first spring 84, an L-shaped bar 85 and a semicircular plate 86, and the upper front side of the storage frame 71 has a word hole 82, a The word hole 82 is slidably connected with a vibrating plate 83, the vibrating plate 83 is positioned at the inner side of the material storage frame 71, the first spring 84 is connected between the material storage frame 71 and the vibrating plate 83, and the upper inner wall rear side of the conical distribution tray 5 An L-shaped rod 85 is connected, and a semicircular plate 86 is connected to the upper side of the L-shaped rod 85, and the semicircular plate 86 cooperates with the vibrating plate 83.

[0037] Pour the rare metal ore into the guide cylinder 73, the rare metal ore will fall on the semi-circular plate 86 and the vibr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com