High-performance compact type direction-changing weft insertion device

A weft insertion device, a compact technology, is used in textiles and papermaking, looms, textiles, etc., and can solve the difficulty of adjusting the movement law of the space four-bar linkage mechanism, the low screw transmission efficiency of the variable-lead screw mechanism, and the differential gear train. The problems such as the long transmission line of the connecting rod mechanism can achieve the effect of reducing structural parts, reducing the structural size and expanding the weft insertion stroke.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

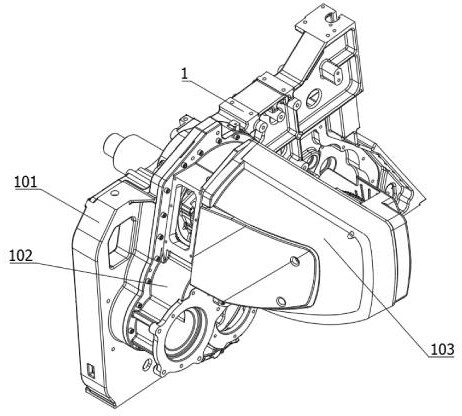

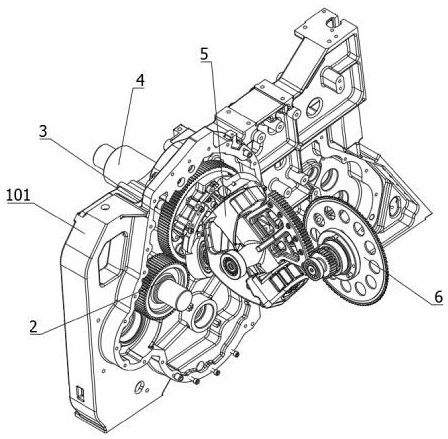

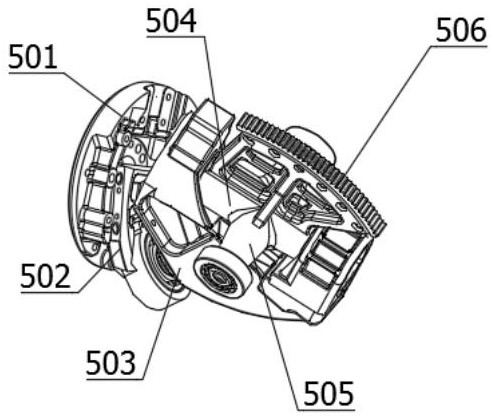

[0030] see Figure 1-4 As shown, a high-performance compact weft insertion device includes a weft insertion mechanism box 1. The weft insertion mechanism box 1 includes a base plate 101, a transmission mechanism installation cavity 102 and a sword transmission mechanism installation cavity 103. The transmission mechanism installation cavity 102 is fixedly connected to the front side of the base plate 101, the sword transmission mechanism installation chamber 103 is fixedly connected to the front side of the transmission mechanism installation chamber 102, the left side of the weft insertion mechanism box body 1 is connected to the drive gear shaft 2 for rotation, and the middle part of the drive gear shaft 2 is fixedly connected There is a driving gear, the middle position of the weft insertion mechanism box body 1 is rotationally connected with a driven gear shaft 4, the front end of the driven gear shaft 4 is fixedly connected with a driven gear 3, the driven gear 3 meshes wi...

Embodiment 2

[0034] see figure 1 , 3 as well as Figure 5-6 As shown, a high-performance compact weft insertion device includes a weft insertion mechanism box 1. The weft insertion mechanism box 1 includes a base plate 101, a transmission mechanism installation cavity 102 and a sword transmission mechanism installation cavity 103. The transmission mechanism installation cavity 102 is fixedly connected to the front side of the base plate 101, the sword transmission mechanism installation chamber 103 is fixedly connected to the front side of the transmission mechanism installation chamber 102, the left side of the weft insertion mechanism box body 1 is connected to the drive gear shaft 2 for rotation, and the middle part of the drive gear shaft 2 is fixedly connected There is a driving gear, the middle position of the weft insertion mechanism box body 1 is rotationally connected with a driven gear shaft 4, the front end of the driven gear shaft 4 is fixedly connected with a driven gear 3, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com