Rolling device for road construction

A rolling device and road construction technology, applied in the field of rolling devices, can solve the problems of unsatisfactory rolling effect and easy residual small potholes on the road surface, and achieve the effect of good flattening effect, sufficient rolling, and flexible adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

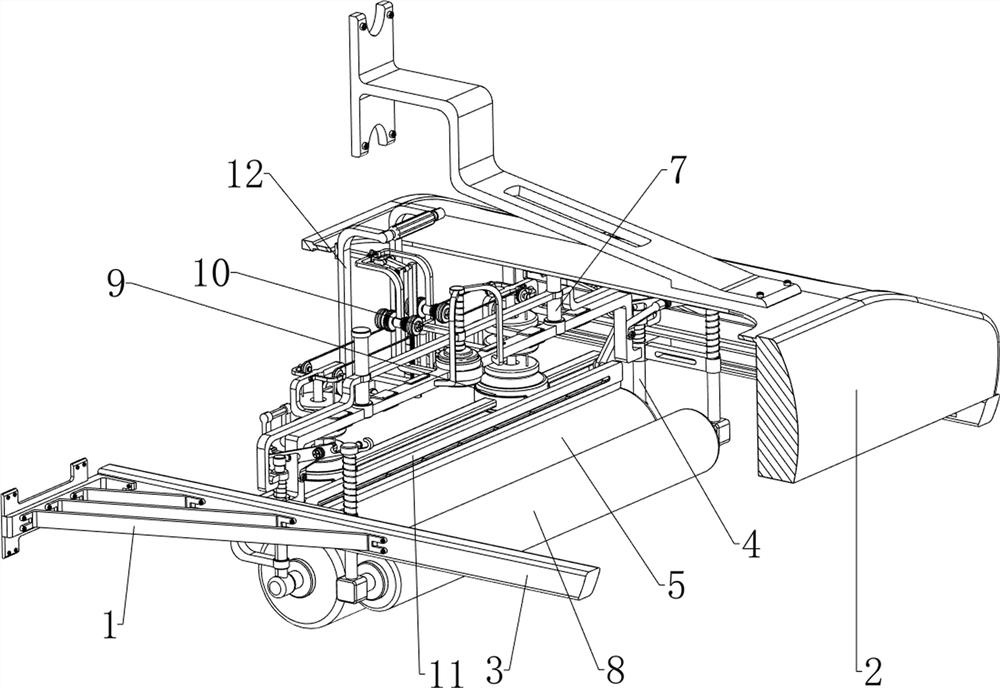

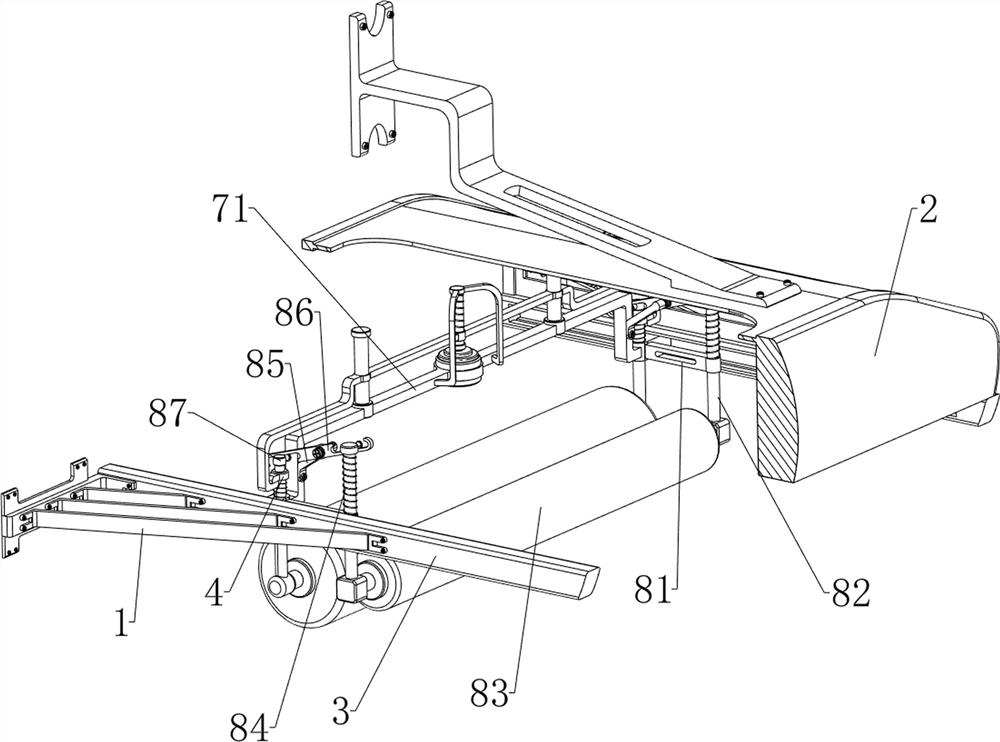

[0036] A rolling device for road construction, in Figure 1-3 As shown in , it includes a first bracket 1, a frame body 2, a rodless cylinder 3, a sliding rod 4, a first roller 5, a first spring 6, a lifting mechanism 7 and a flattening mechanism 8, and the bottom of the frame body 2 is symmetrical front and rear Rodless cylinder 3 is installed, and the first support 1 is all connected with the mode of bolt connection on the left side front and back side walls of two rodless cylinders 3, and the all sliding connection on the moving parts of two rodless cylinders 3 Sliding rods 4, between the lower sides of the two sliding rods 4, there is a first roller 5 that can flatten road potholes and bumps, and the upper side of the two sliding rods 4 and the rodless cylinder 3 on the same side The first spring 6 which acts as a buffer is connected between the tops of the moving parts, and the lifting mechanism 7 which is convenient for switching the rolling mode is connected between the...

Embodiment 2

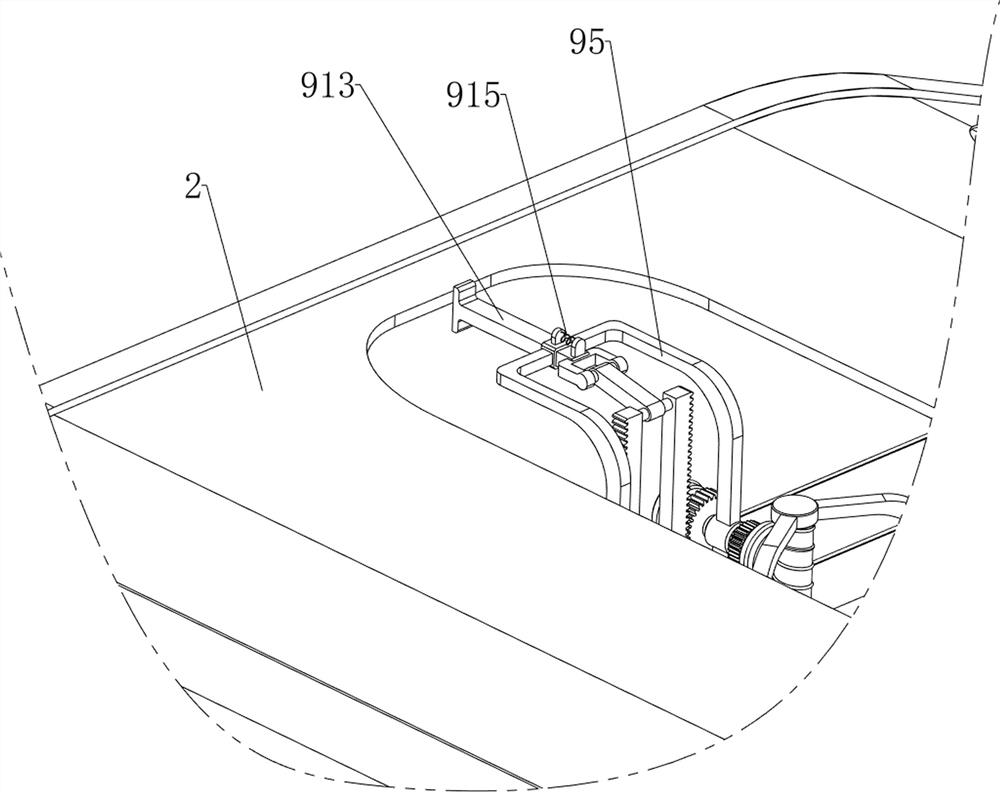

[0041] On the basis of Example 1, in image 3 , Figure 7 , Figure 8 with 9 As shown in the figure, it also includes a weighting mechanism 9, and the weighting mechanism 9 includes a material receiving frame 91, a third support 92, a fourth support 93, a first winding wheel 94, a fifth support 95, a second winding wheel 96, Stay cord 97, iron block 98, the third slide bar 99, the first rack 910, the third spring 911, the first gear 912, push block 913, the second fork 914 and the fourth spring 915, two slide bars 4 The lower part of the frame is connected with a receiving frame 91, and the front and rear sides of the connecting frame 71 are connected with a third bracket 92 by means of bolt connection, and the left and right sides of the two third brackets 92 are welded with a fourth bracket 93 for supporting , the four fourth brackets 93 are all rotatably provided with a first reel 94, the left side wall in the middle of the connecting frame 71 is provided with a fifth br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com