Round nut flat-milling device

A round nut milling and flattening technology, which is applied in the field of round nut milling and flattening devices, can solve the problems of slow fixing speed, failure to meet mass production requirements, and low efficiency, and achieve high processing efficiency, convenient and reliable workpiece clamping, and accurate positioning Effect

Inactive Publication Date: 2015-09-09

GUIZHOU HANGRUI AVIATION PRECISION PARTS MFG

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] Round nuts need to be milled and flattened during the processing process; in the traditional milling and flattening process, at the beginning of production, because the shape of the part is disc-shaped, the flat-nose pliers are used to clamp the part first, and the procedure for fixing the flat-nose pliers is complicated, and the fixed When turning the lead screw with a wrench, the movable clamp body is driven by the lead screw nut to move, and then the workpiece is clamped or loosened. After the workpiece is clamped, the end milling machine can be used for milling; On the other hand, this method is slow in clamping and low in efficiency; when milling workpieces with this method, due to the slow fixing speed, it cannot meet the requirements of mass production

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment the technical solution of the present invention is further described:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

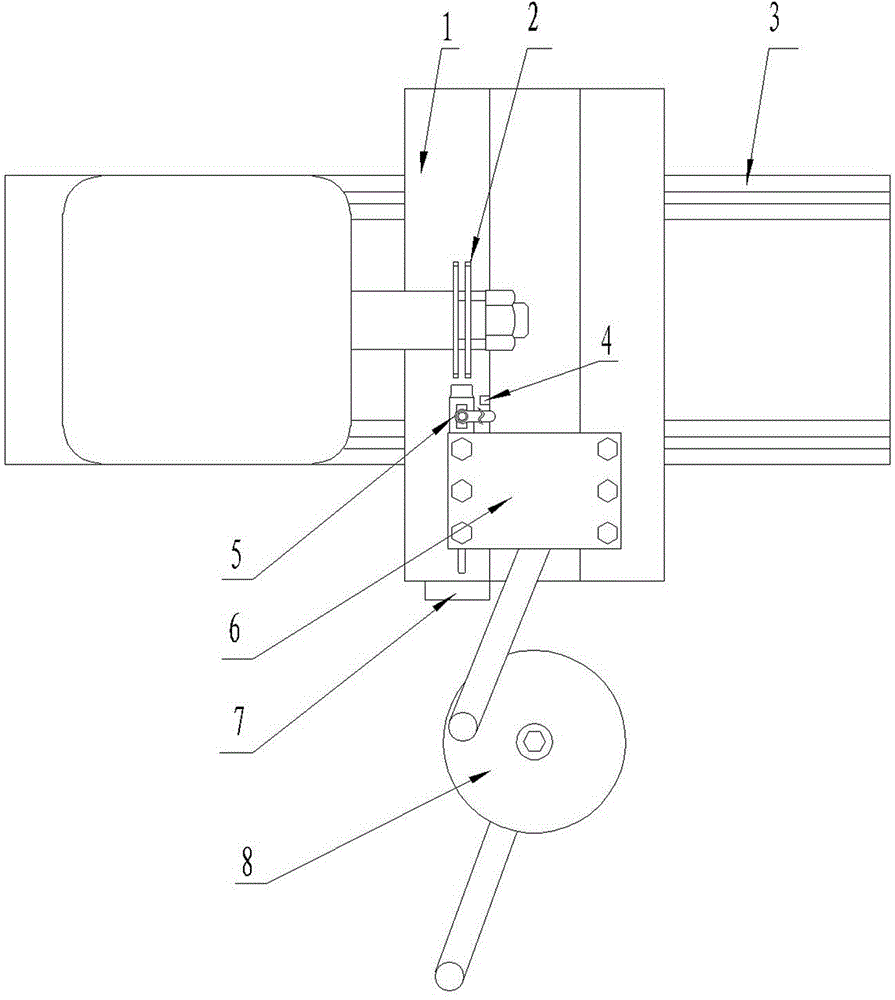

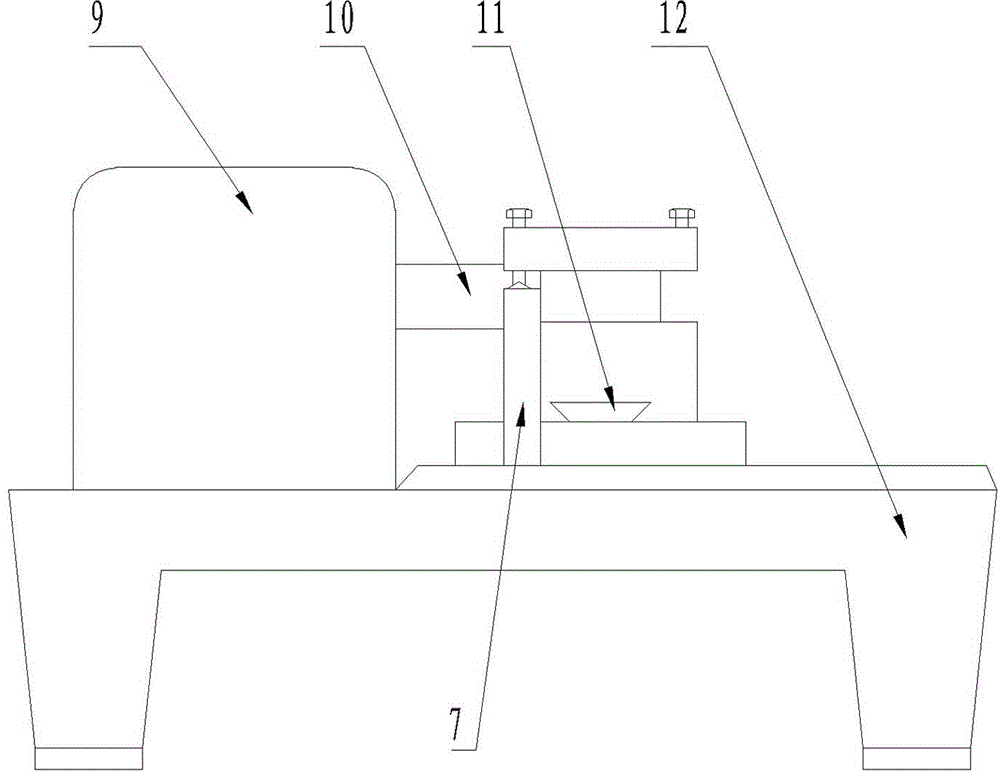

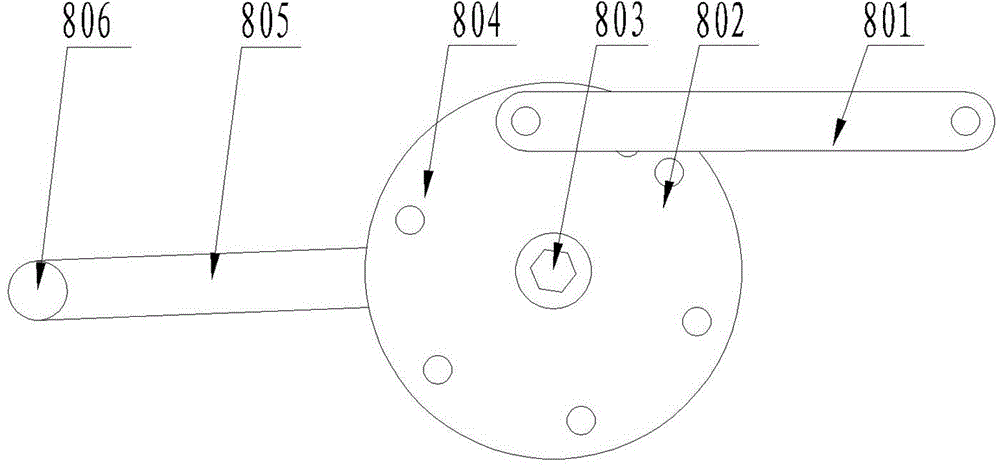

The invention discloses a round nut flat-milling device in the mechanical manufacturing field. The round nut flat-milling device comprises a machine tool which is provided with a motor, an output end of which is connected with a main shaft. A disk milling cutter blade is arranged on the circumference of the main shaft. A round nut flat-milling fixture is arranged just opposite to the disk milling cutter blade. The round nut flat-milling fixture is fixed to a knife rest, one side of which is connected with a power unit. The power unit comprises a rotating disk. A connecting rod is mounted on the upper surface of the rotating disk, and the lower surface of the rotating disk is connected with a rocking bar. A bearing is installed at the central position of the rotating disk. The machine tool is provided with a guide rail which is slidingly connected with a supporting plate. A discharging stop piece is fixed to the outer edge of the supporting plate. The discharging stop piece is directly facing the round nut flat-milling fixture. The upper surface of the supporting plate is provided with a slide rail which is slidingly connected with a chute arranged at the bottom of the knife rest. By the scheme, problems such as workpiece clamping trouble, positioning difficulty and low processing efficiency during machining process of round nuts are solved.

Description

technical field [0001] The invention belongs to the field of round nut processing, and in particular relates to a round nut milling and flattening device. Background technique [0002] Round nuts need to be milled and flattened during the processing process; in the traditional milling and flattening process, at the beginning of production, because the shape of the part is disc-shaped, the flat-nose pliers are used to clamp the part first, and the procedure for fixing the flat-nose pliers is complicated, and the fixed When turning the lead screw with a wrench, the movable clamp body is driven by the lead screw nut to move, and then the workpiece is clamped or loosened. After the workpiece is clamped, the end milling machine can be used for milling; On the other hand, this method is slow in clamping and low in efficiency; when milling workpieces with this method, due to the slow fixing speed, it cannot meet the requirements of mass production. Contents of the invention [0...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23C3/00B23Q7/00

CPCB23C3/00B23Q7/00

Inventor 王世敏

Owner GUIZHOU HANGRUI AVIATION PRECISION PARTS MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com