Corner flattening mechanism for framing machine

A framing machine and corner technology, which is applied in sustainable manufacturing/processing, electrical components, climate sustainability, etc., can solve the problems of damage to the corners of solar modules, bulky machine appearance, and not beautiful enough to achieve beautiful appearance and high durability. Even force, better effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

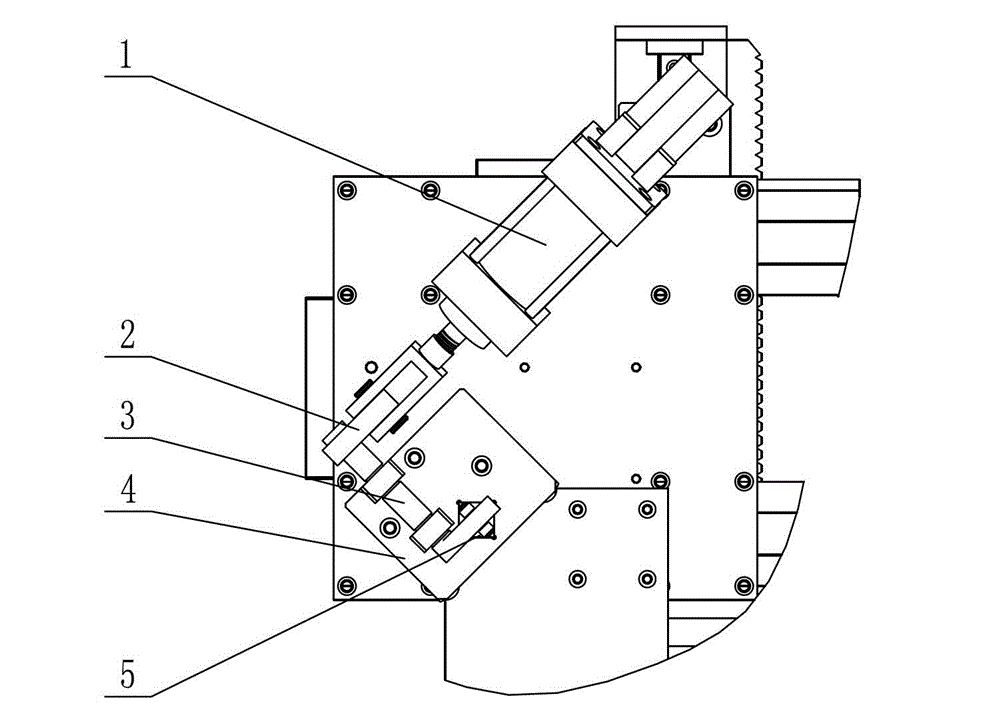

[0011] The present invention will be further described below in conjunction with specific drawings.

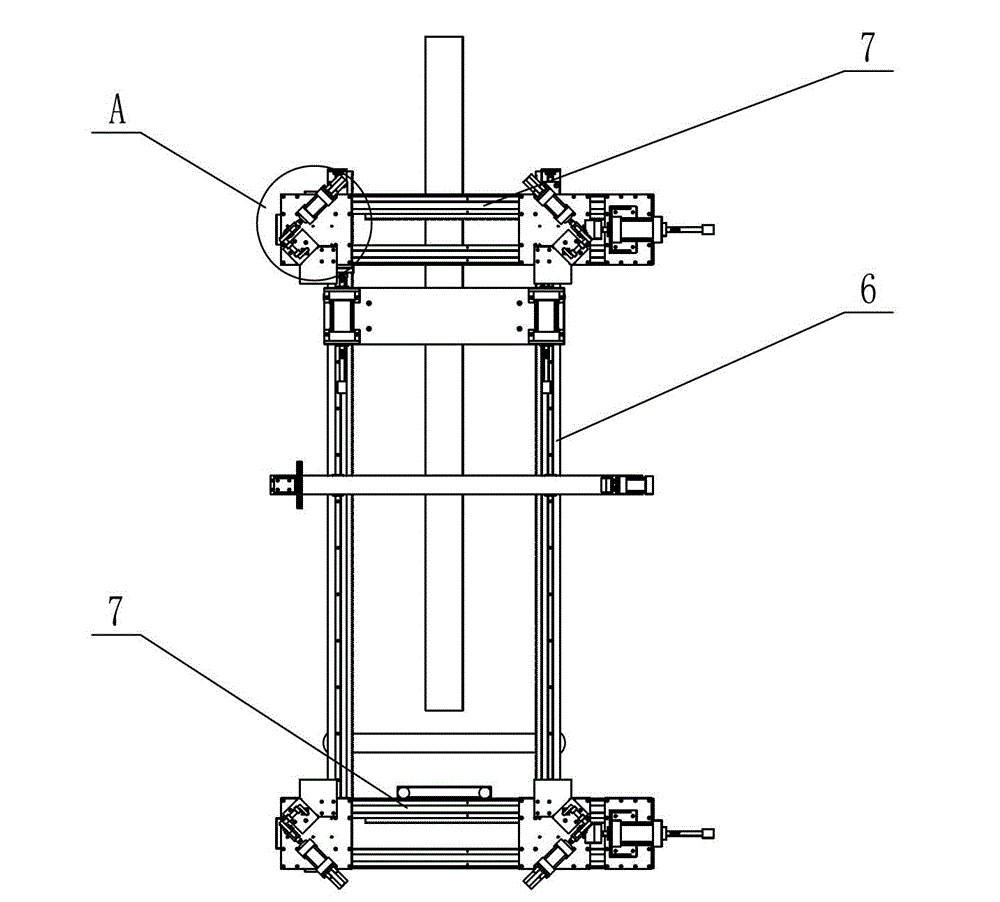

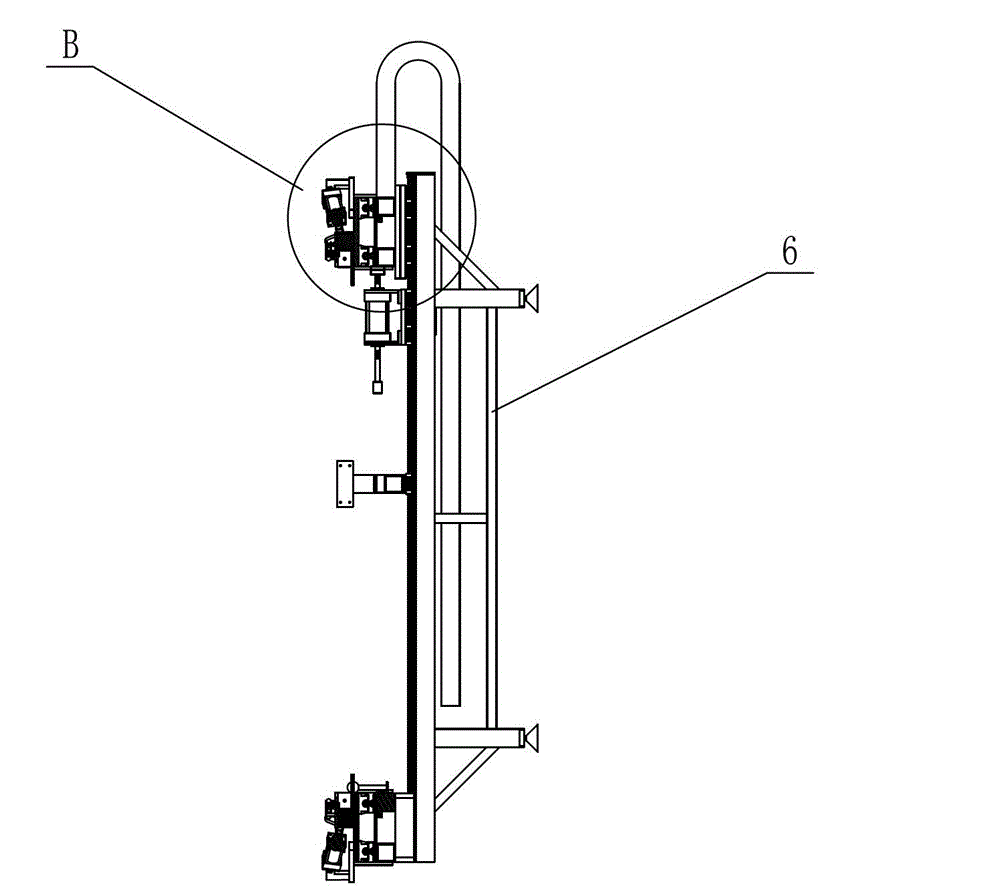

[0012] Such as Figure 1 ~ Figure 4 As shown: the corner flattening mechanism of the framing machine includes a pressing cylinder 1, a connecting arm 2, a rotating lever 3, a rotating pressing block 4, a connecting seat 5, a framing machine 6, and the like.

[0013] Such as image 3 , Figure 4 As shown, the present invention includes a compression cylinder 1 installed at the four corners of the framing machine 6, the piston rod of the compression cylinder 1 is rotatably connected to one end of the connection arm 2, and the other end of the connection arm 2 is connected to the rotary lever 3 One end of the rotary lever 3 is connected with the connecting seat 5, and the connecting seat 5 is rotationally connected with the rotary briquetting block 4, and the bottom of the connecting seat 5 is slidably matched with the rotary briquetting block 4.

[0014] Such as figure 1 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com