Submarine cable laying device for ocean engineering construction

A technology for marine engineering and laying devices, which is applied in construction, earth movers/excavators, etc., can solve the problems that laying devices cannot be realized, affect the effect of cable laying, and the unevenness of the seabed ground, so as to ensure the efficiency of laying and laying. quality, reduce the overall tilt, improve the quality of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

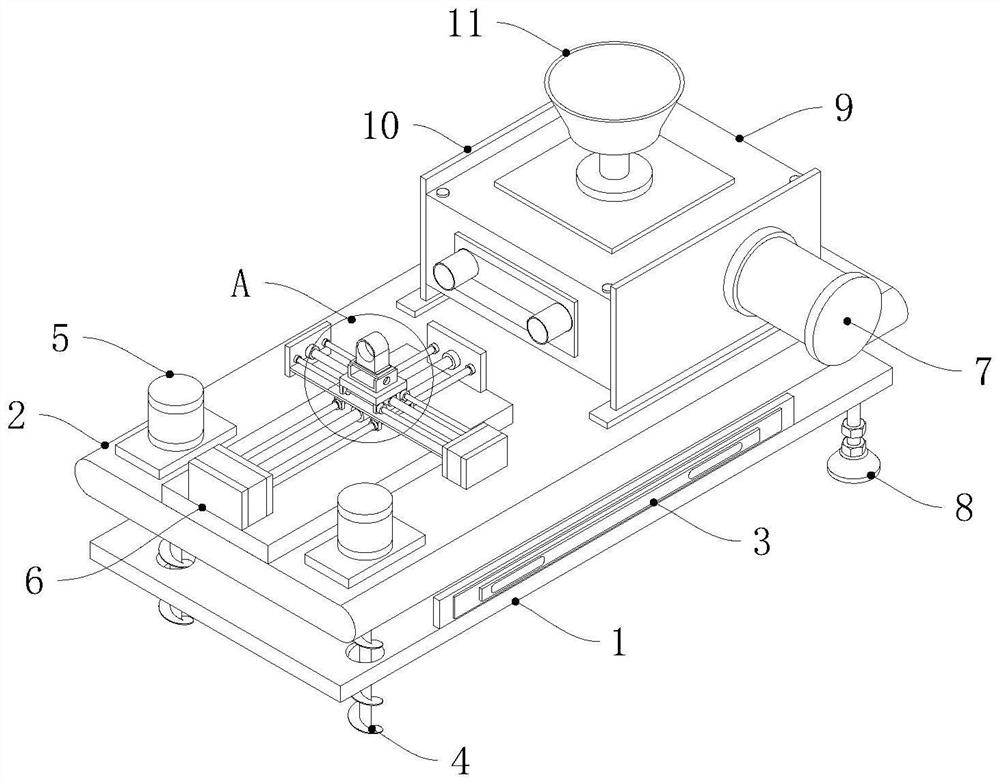

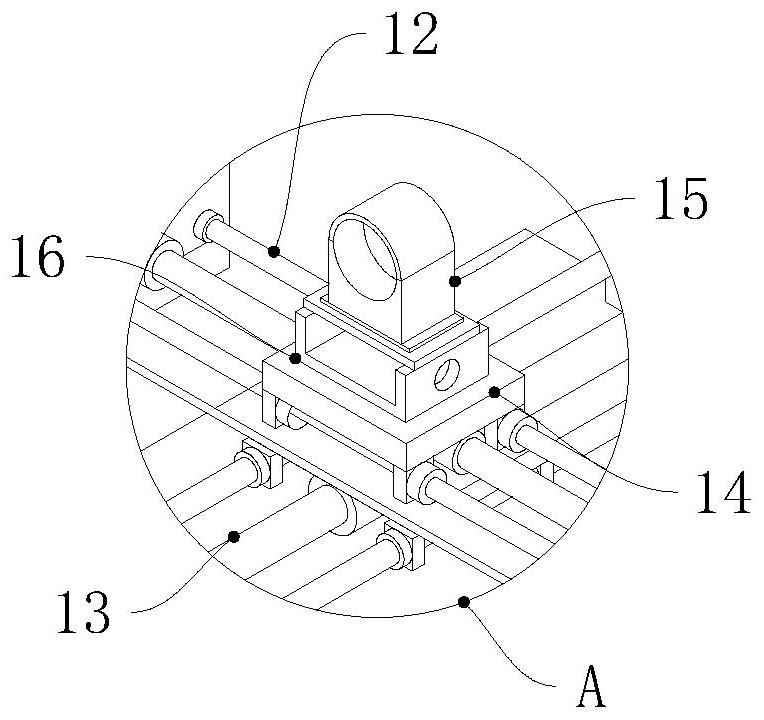

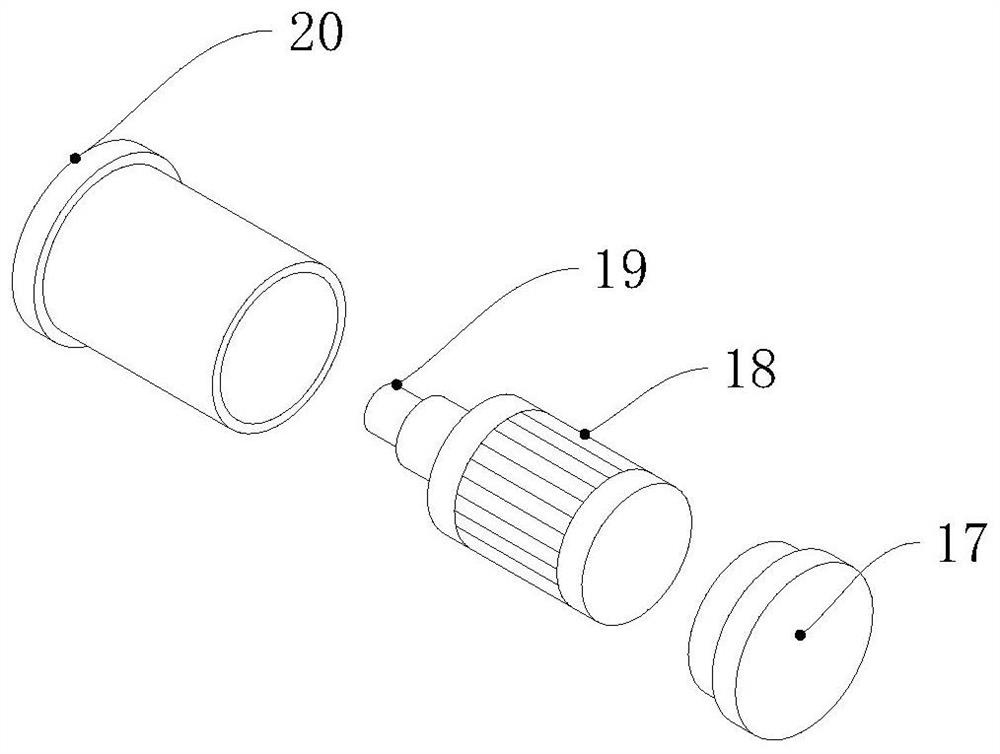

[0026] Example: such as figure 1 As shown, a submarine cable laying device for marine engineering construction of the present invention includes a base plate 1 and a laying plate 2, the top of the base plate 1 is provided with a laying plate 2, and the front middle part of the base plate 1 and the laying plate 2 is horizontally provided with a spirit level 3, An installation box 9 and a moving mechanism 6 are respectively arranged on the top lateral sides of the laying board 2, and one end of the laying board 2 is fixedly provided with a first motor 5, and the output end of the first motor 5 is connected with a helical roller 4 through transmission. On the base plate 1, and extend to the bottom of the base plate 1; after the overall equipment enters the sea, the two sides of the end of the base plate 1 are provided with feet 8, which are set horizontally, and the drilling depth of the helical roller 4 is completed according to the horizontal distance displayed by the spirit lev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com