Adjustable PP centrifugal fan for waste gas treatment washing tower

A centrifugal fan and waste gas treatment technology, which is applied to the components of pumping devices for elastic fluids, mechanical equipment, machines/engines, etc., and can solve the problems of cumbersome installation process, time-consuming and laborious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

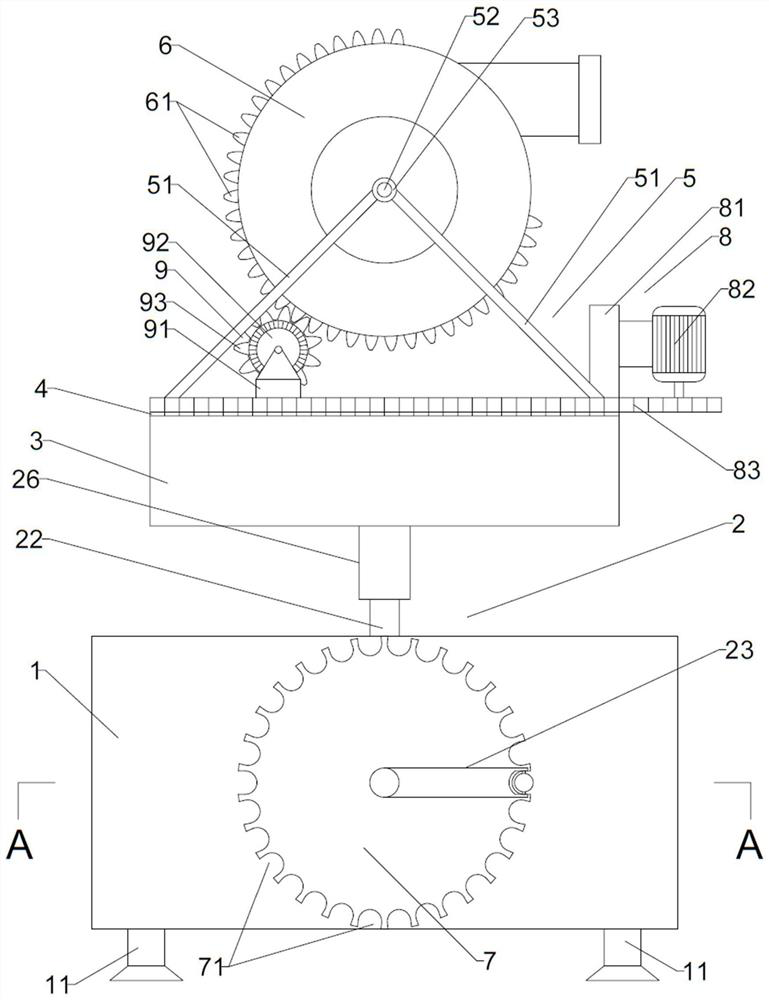

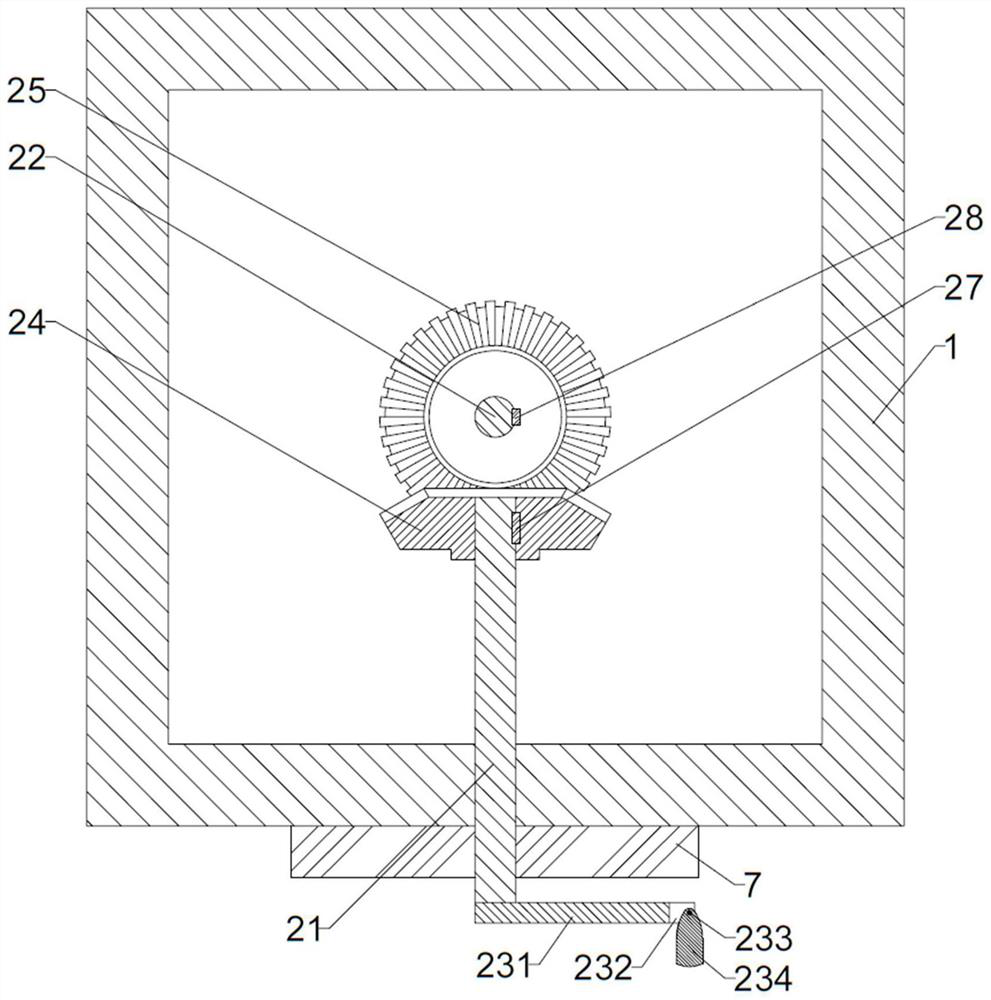

[0026] Such as Figure 1-2 The adjustable PP centrifugal fan used in the exhaust gas treatment scrubber includes a base 1, a height adjustment mechanism 2, a bottom plate 3, a gear plate 4, a fan bracket 5, and a PP centrifugal fan 6. The base 1 is a groove type, and the The height adjustment mechanism 2 is located in the base 1, the base plate 3 is located on the height adjustment mechanism 2, the gear plate 4 is rotatably located on the base plate 3, and the fan support 5 is fixed on the gear plate 4, so The PP centrifugal fan 6 is rotatably mounted on the fan bracket 5 , and a group of fan tooth blocks 61 are arranged outside the PP centrifugal fan 6 .

[0027] Wherein, the fan support 5 includes four support rods 51, two support connecting rods 52, and two bearings 52, and each two support rods 51 are fixed on the gear plate 4 in a triangular shape, and the four support rods 51 Form two symmetrical triangular brackets, the top of the triangular bracket is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com