Projection welding nut with annularly distributed welding legs

A technology of projection welding nuts and welding legs, applied in nuts, welding equipment, threaded fasteners, etc., can solve the problems of high cost, long time, low efficiency, etc., and achieve the effect of solving high cost and improving bonding force and strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

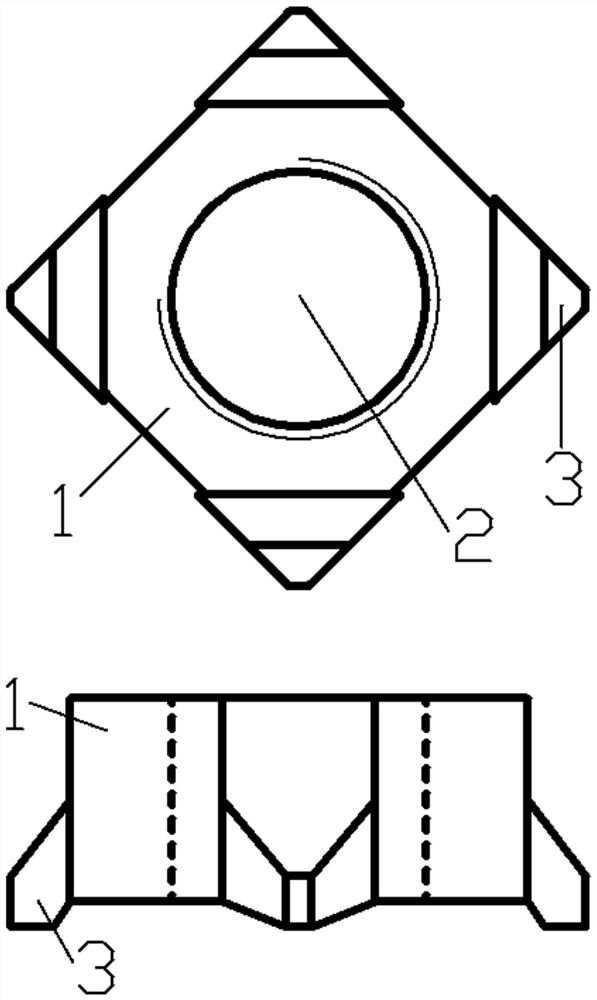

Image

Examples

Embodiment 1

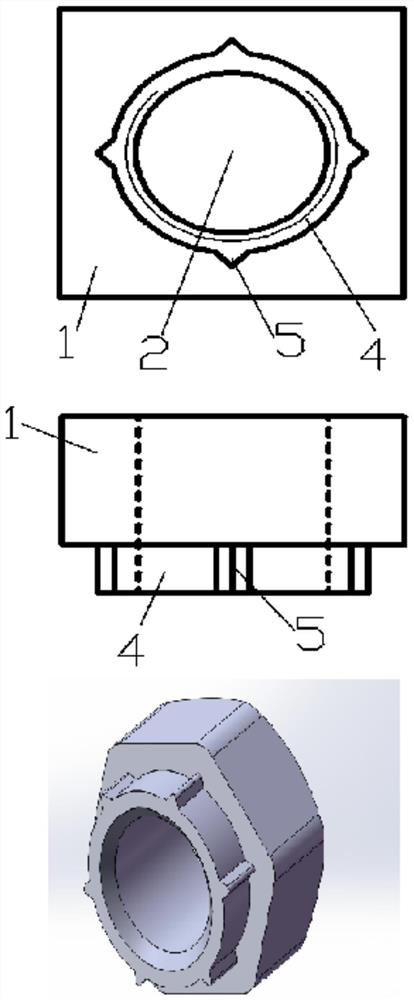

[0028] A projection welding nut with circular distribution of welding feet, such as figure 2 As shown, it includes a head plate 1 and a columnar portion 4. The middle part of the head plate 1 and the columnar portion 4 forms a through portion 2; the columnar portion 4 is provided with four circularly distributed longitudinal welding feet 5 that are separated from each other.

Embodiment 2

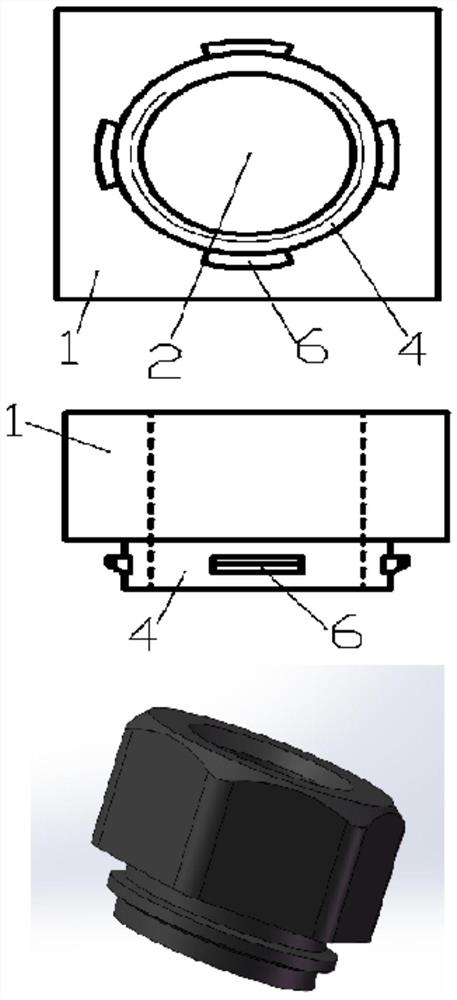

[0030] A projection welding nut with circular distribution of welding feet, such as image 3 As shown, it includes a head plate 1 and a columnar portion 4. The middle part of the head plate 1 and the columnar portion 4 forms a through portion 2; the columnar portion 4 is provided with four circularly distributed transverse welding feet 6 that are separated from each other.

Embodiment 3

[0032] A projection welding nut with circular distribution of welding feet, on which the base surface of the longitudinal welding feet 5 is gradually enlarged, as shown in Figure 4 As shown, the farther the distance from the head plate 1 is, the larger the base surface of the longitudinal welding leg 5 is, and the rest are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com