Preparation of 2,5-Dimethylfuran by Electrocatalytic Reduction of 5-Hydroxymethylfurfural Using Doped ZrO2 Graphite Electrode

A technology of hydroxymethyl furfural and dimethyl furan is applied in the field of biomass energy chemical industry and achieves the effects of good application prospect, good selectivity and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Accurately weigh 18.80g of fructose and 3.43g of NH with an electronic balance 4 Br, 0.12gZnCl 2 Put it into a 250ml round bottom flask, accurately measure 150.0ml of N,N-dimethylacetamide with a pipette, put it into the round bottom flask, add magnets, reflux and stir in an oil bath at 120°C for 55min. After the reaction is over, remove the ground glass plug on the round bottom flask cover and cool to room temperature with running water, and the concentration of the prepared 5-hydroxyfurfural stock solution is 100g.L -1 , with a brown bottle for equipment.

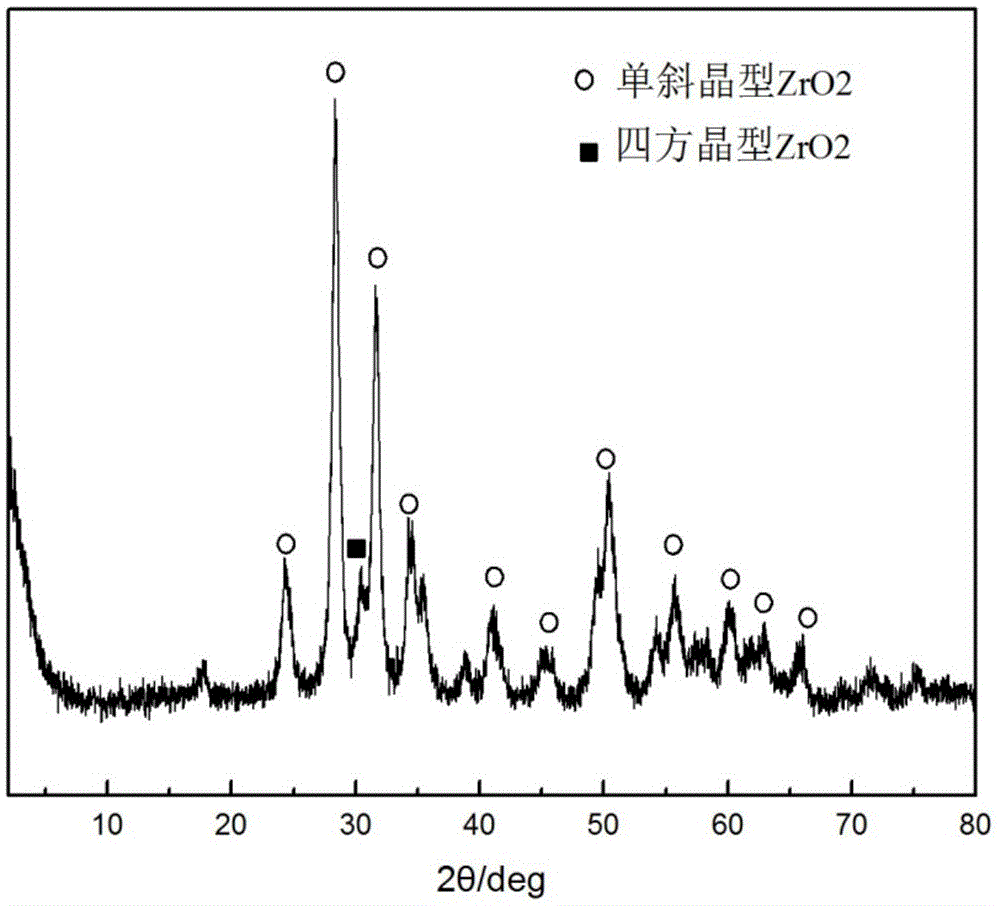

[0038] (2) Weigh 4.00g of graphite, 4.00g of polytetrafluoroethylene emulsion with a mass fraction of 60%, 0.12g of ZrO 2 (The relative graphite mass percentage is 3%) into the reactor, add 20mL of absolute ethanol and magnetically stir for 10min; the obtained ZrO 2- Heat the graphite mixture with stirring to evaporate the ethanol, stop heating when the mixture becomes a paste solid, pour the paste solid int...

Embodiment 2

[0044] Embodiment 2 Change doping ZrO 2 The relative graphite mass percentage is 8% to prepare ZrO 2 Graphite electrode, other conditions and operation steps are identical with embodiment 1. The calculated concentration of 2,5-dimethylfuran is 6.15g.L -1 , and the yield was 30.75%.

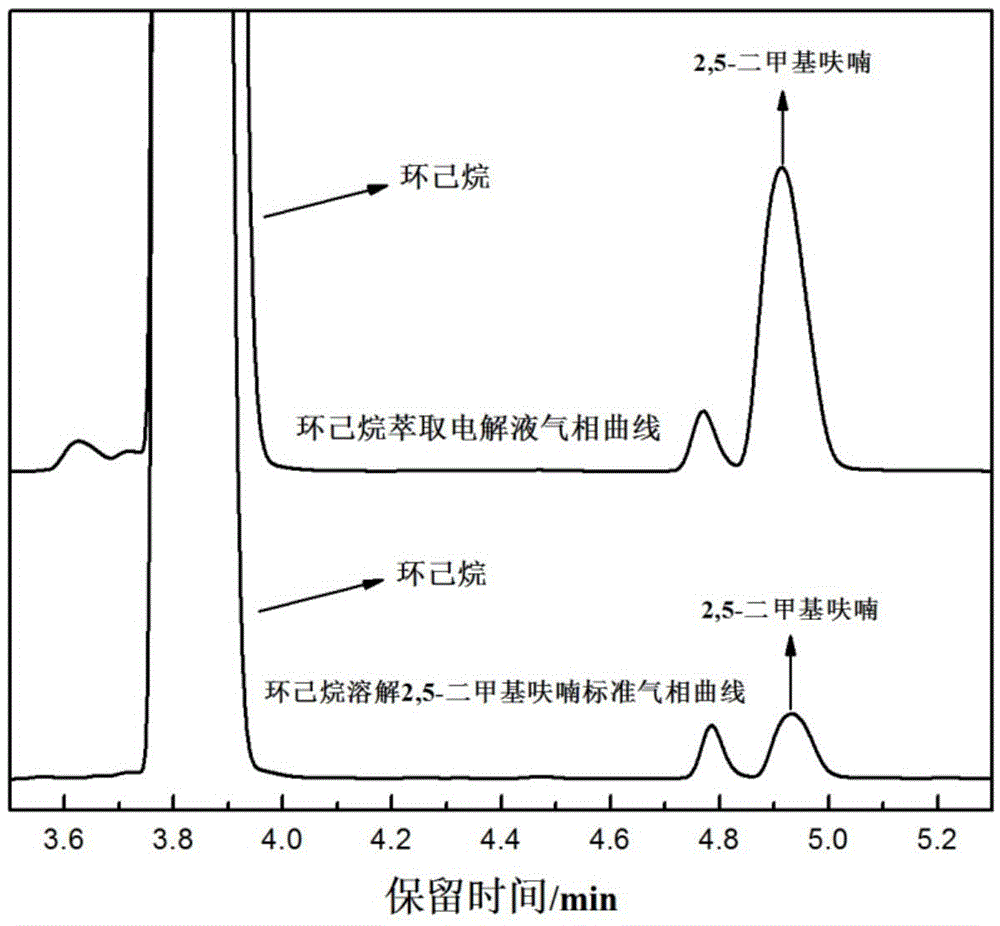

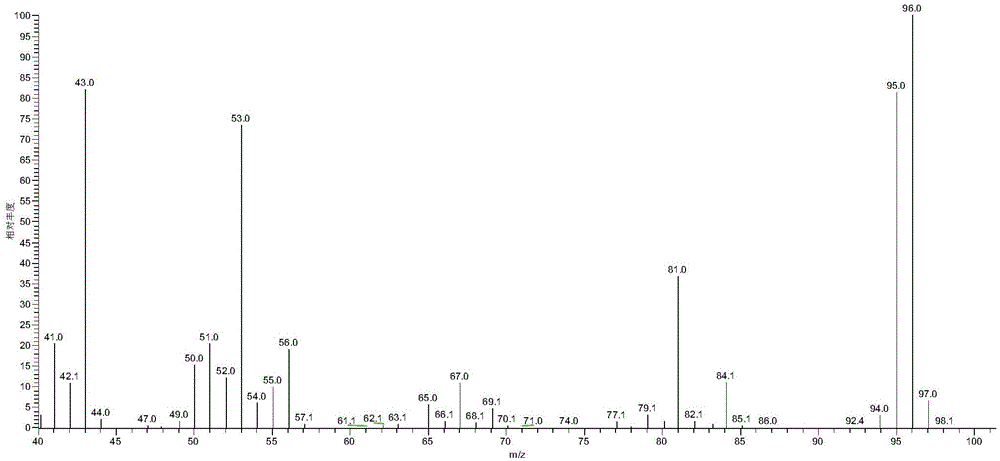

[0045] As can be seen from the foregoing examples, the present invention has investigated ZrO 2 The effect of doping amount on the yield of 2,5-dimethylfuran prepared by catalytic hydrogenation reduction of 5-hydroxyfurfural, the concentration of the obtained 2,5-dimethylfuran is 0.55~6.15g.L -1 . The preparation of 2,5-dimethylfuran by electrochemical catalytic hydrogenation reduction of 5-hydroxyfurfural has mild reaction conditions, simple equipment, low cost and novel method. 5-Hydroxyfurfural in the electrolyte diffuses from the solution and adsorbs to ZrO under the action of the solution potential during electrocatalytic reduction 2 - graphite electrode surface, in ZrO 2 Under the acti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com