Diamond roller finished product detection device

A diamond roller, finished product inspection technology, applied in measuring devices, workpiece clamping devices, instruments, etc., can solve the problems of general tightness, inability to quickly perform multi-point inspection, etc., to facilitate directional inspection, improve accuracy, The effect of improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

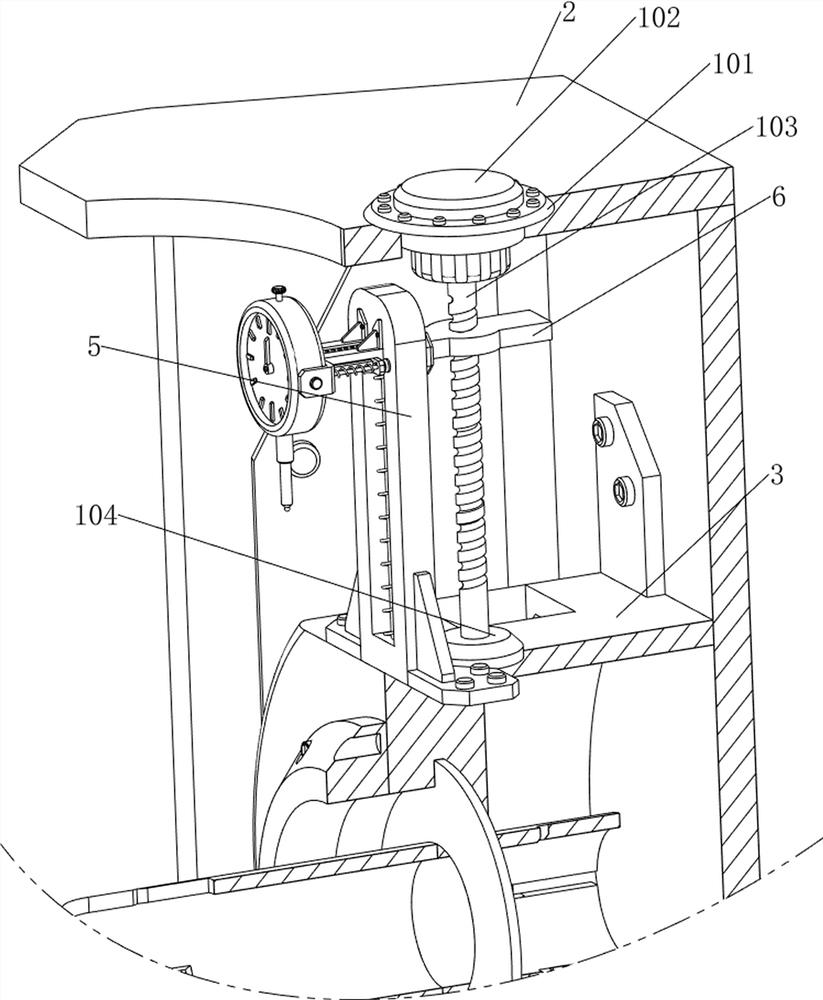

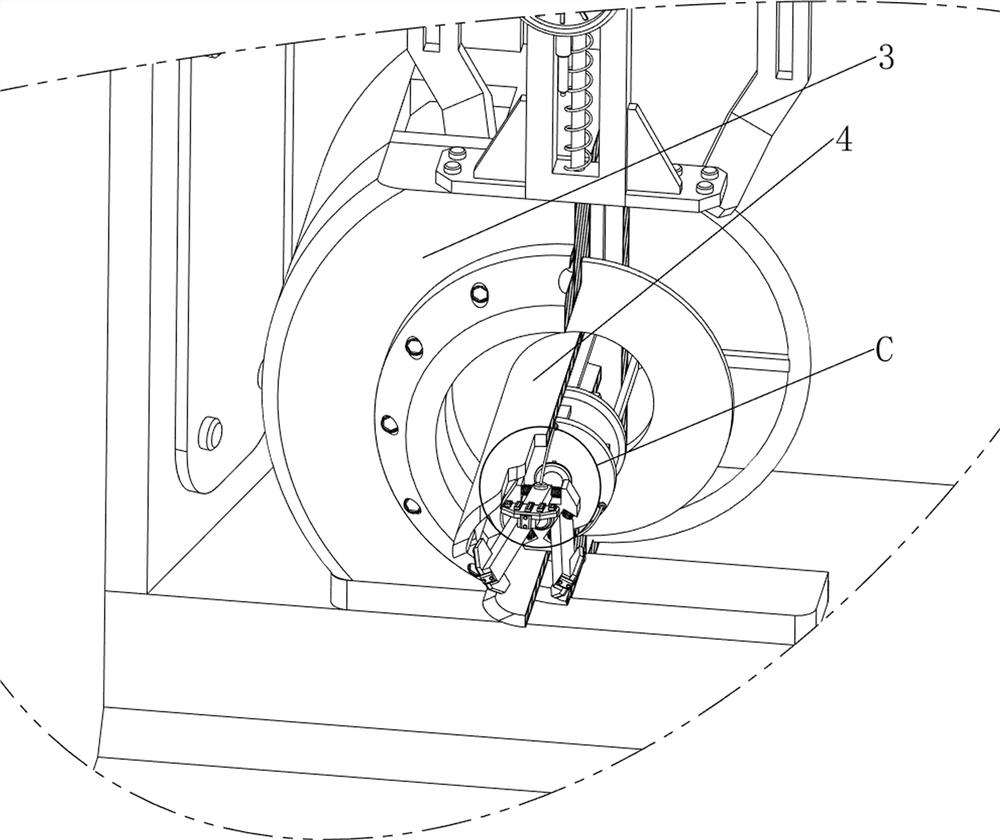

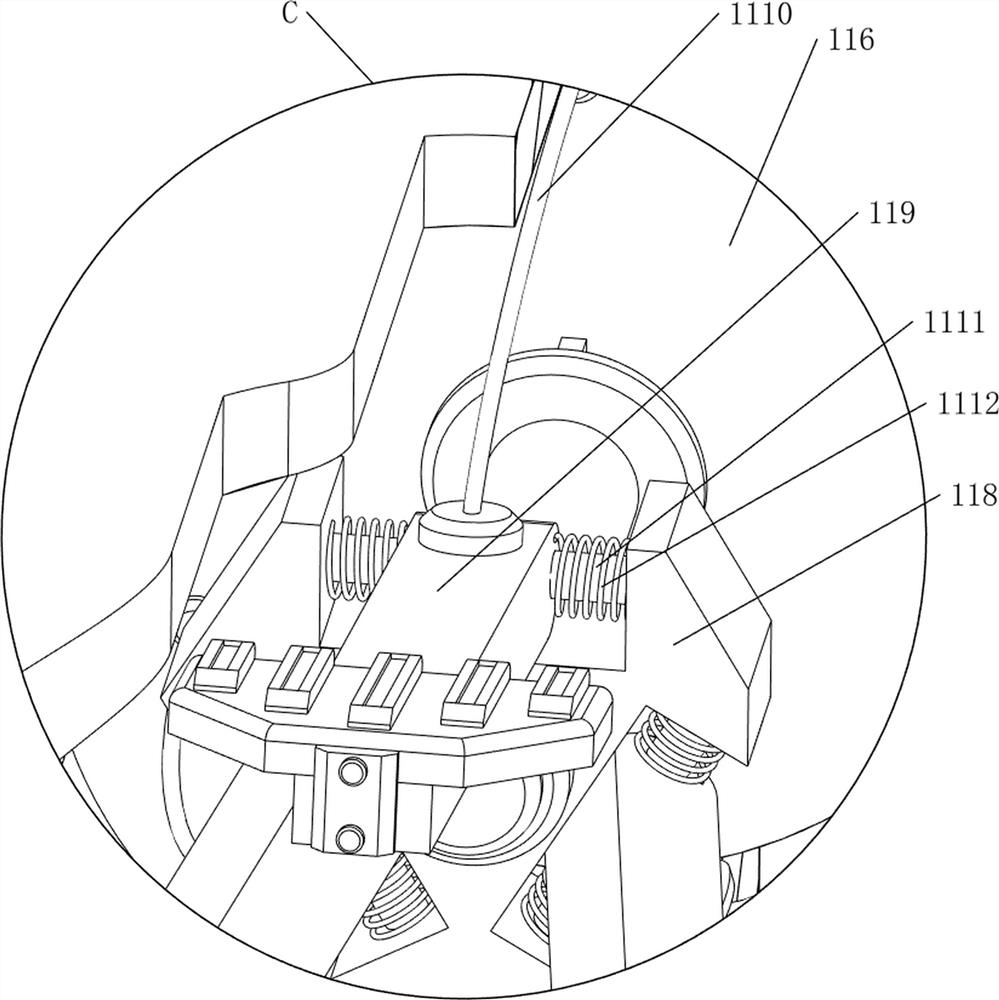

[0040] A diamond roller finished product detection device, such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown, it includes a base 1, a casing 2, a working frame 3, a rolling frame 4, a first guide frame 5, a first slider 6, a detector 7, a second slider 71, a first slider 72, and a first spring 73. The second sliding rod 8, the second spring 9, the testing mechanism 10, the fixing mechanism 11 and the rotating mechanism 12, the top of the base 1 is welded with the shell 2, and the lower part of the shell 2 is fixedly provided with the working frame 3, and the middle part of the working frame 3 passes through The way of the bearing is provided with a rolling frame 4, the front side of the top of the working frame 3 is connected with the first guide frame 5 by bolts, the second slide bar 8 is connected between the upper and lower sides of the middle part of the first guide frame 5, and the upper part of the second slide bar 8 The sliding type is prov...

Embodiment 2

[0046] On the basis of Example 1, such as Figure 4 with Figure 12 As shown, it also includes an adapter mechanism 13, and the adapter mechanism 13 includes a telescopic rod 131, a third spring 132 and a push plate 133, and eight telescopic rods 131 are evenly spaced around the middle of the rolling frame 4, and the telescopic rods 131 A push plate 133 is connected between the telescopic ends, and a third spring 132 is wound around the telescopic rod 131 .

[0047] Due to the different sizes and specifications of the finished diamond rollers to be tested, after the finished diamond rollers are placed on the rolling frame 4, the rear side of the finished diamond rollers is in contact with the connecting rod 113, and the pressure plate 119 will push the diamond rollers when blocking the front side of the finished diamond rollers. The finished product slides backwards, and the finished product of the diamond roller can be adapted according to its size and specifications, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com