Anti-bacterial coating smearing device and method capable of achieving rapid drying and used for sterile instrument processing

An antibacterial coating and fast drying technology, which is applied to the surface coating device, coating, spraying device, etc., can solve the problems of labor-intensive, low processing efficiency, troublesome operation, etc., and achieve the effect of convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

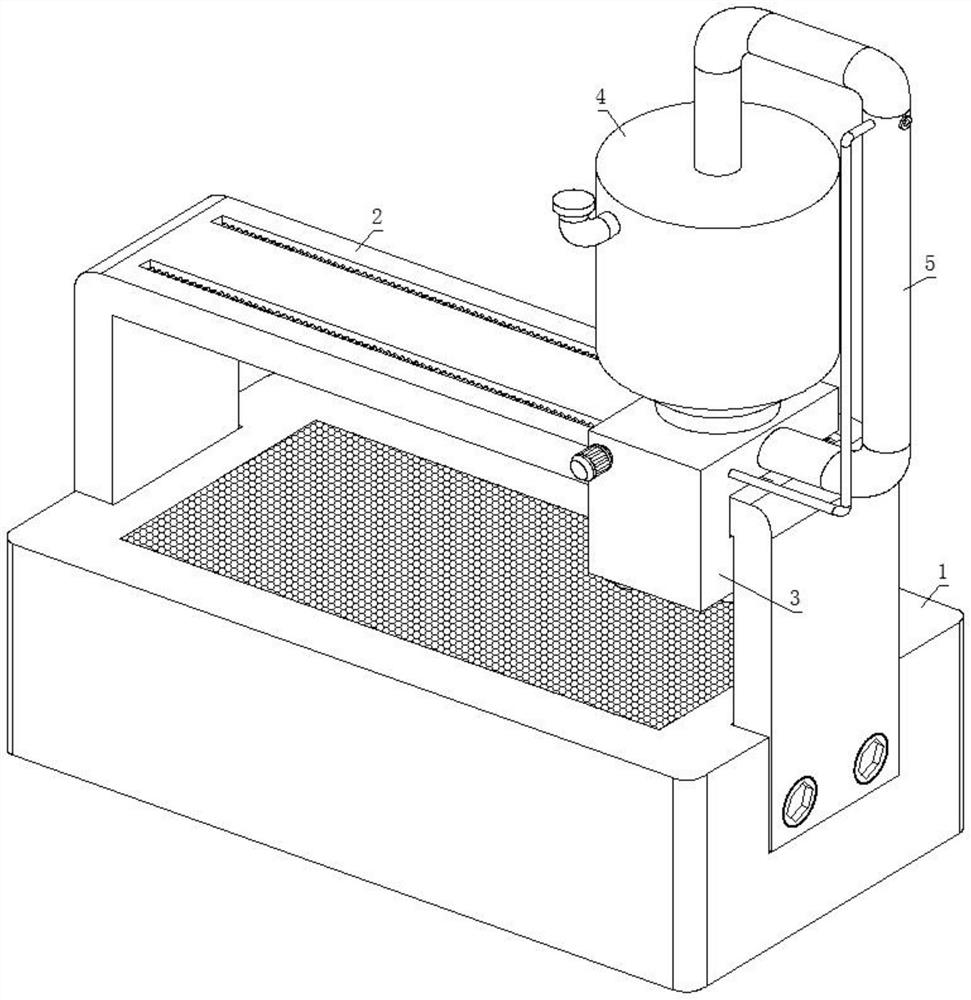

[0051] In order to further better explain the above-mentioned embodiments, the present invention also provides an embodiment, a method for implementing a fast-drying antibacterial coating application device for aseptic instrument processing, comprising the following steps:

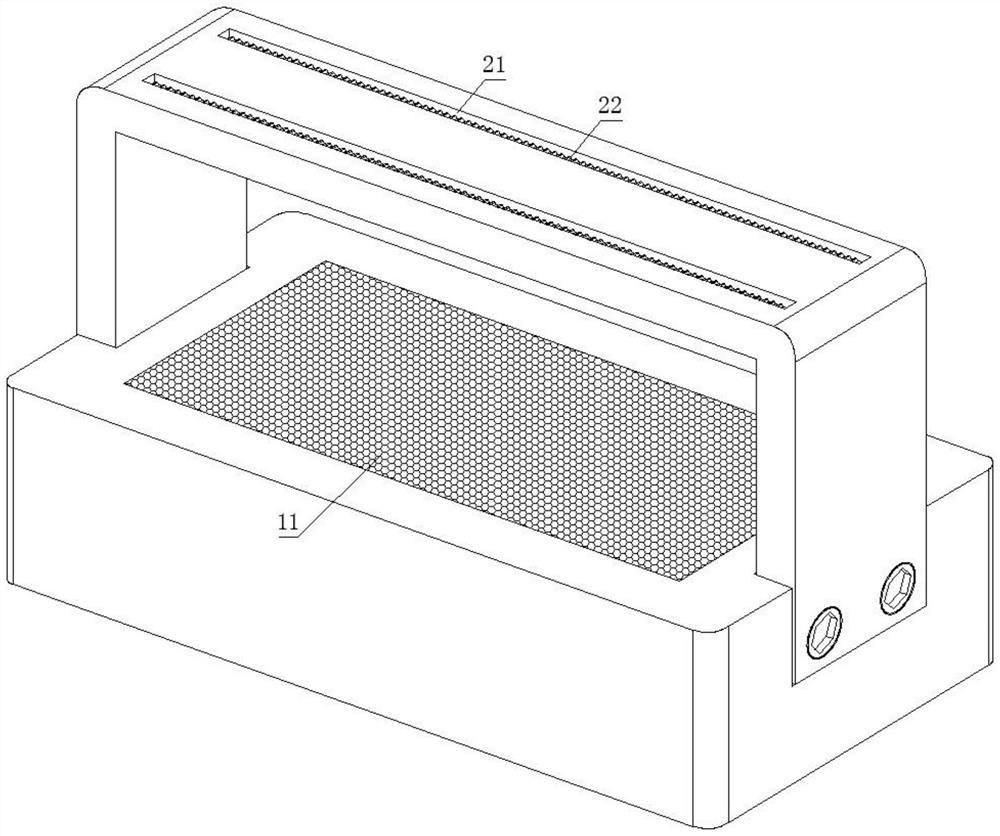

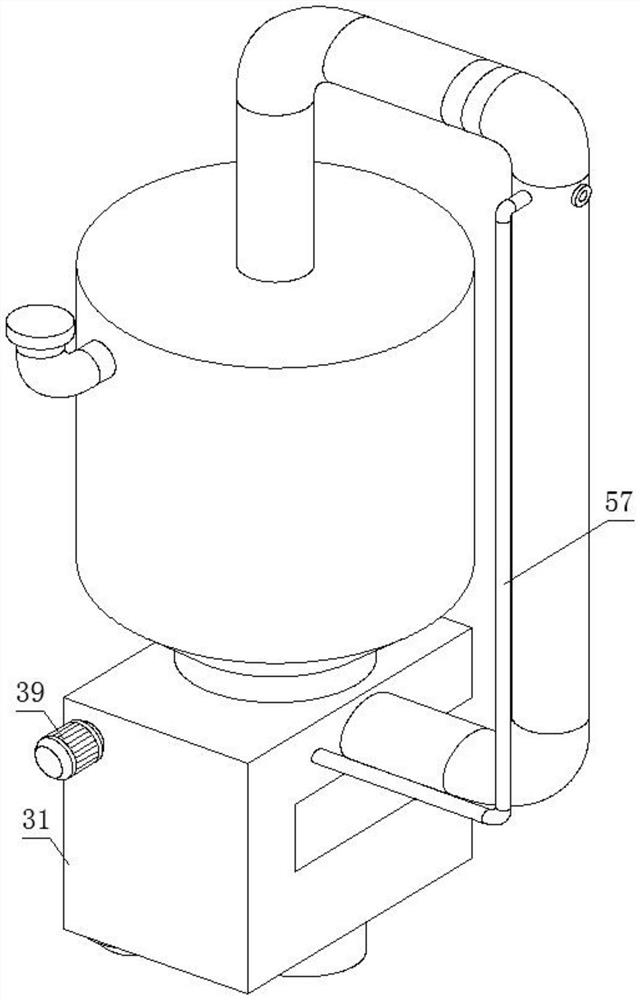

[0052] Step 1: After adding the liquid coating raw material from the feeding port of the storage barrel 4, after placing the sterile instrument on the drain screen 11, start the drive motor 391, and the drive motor 391 will drive the drive gear 392 to rotate, and the Under the action of the block 22, the spraying and drying assembly 3 is moved forward as a whole;

[0053]Step 2: When the first driven gear 323 and the second driven gear 324 move forward, they will rotate counterclockwise under the action of the tooth block 22, so as to drive the second gear 341 Rotating counterclockwise, the second gear 341 can drive the one-way gear 343 to rotate clockwise;

[0054] Step 3: After the triangular clamping b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com