Fastener batch assembly process device and assembly process method

An assembly process and fastener technology, applied in workpiece clamping devices, assembly machines, metal processing, etc., can solve problems such as affecting production progress, time-consuming and labor-intensive, and affecting production efficiency, saving labor costs and reducing assembly. Time, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

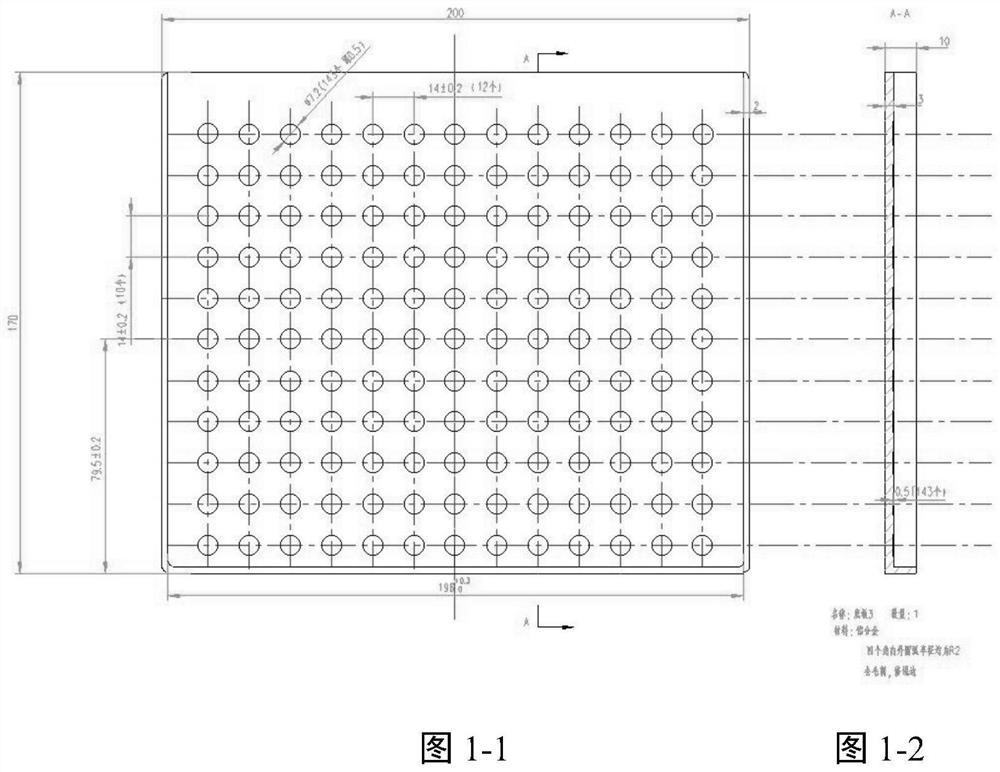

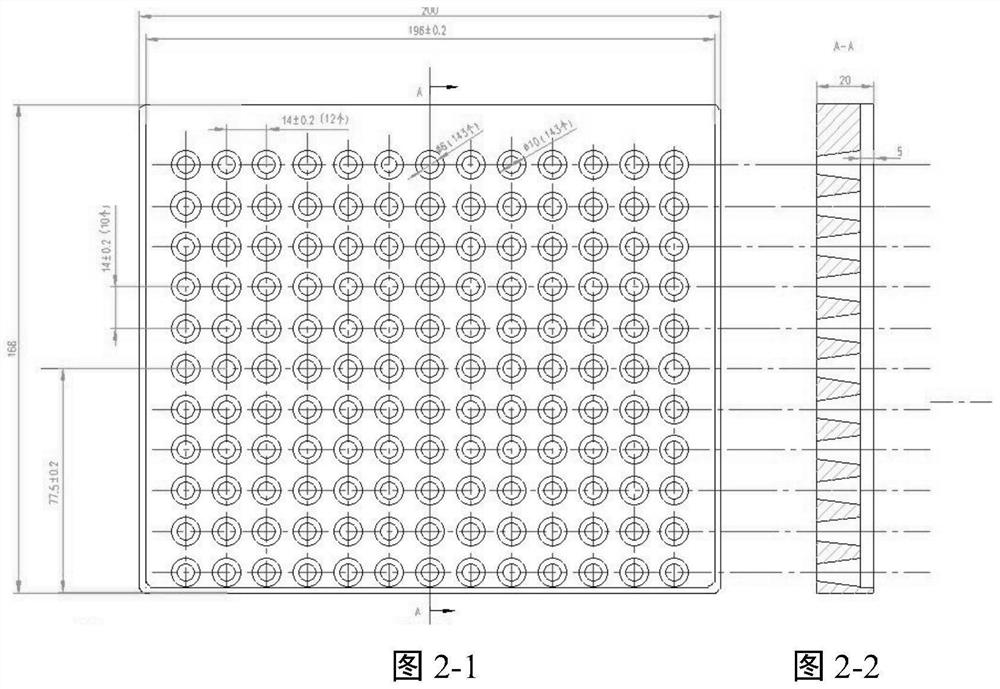

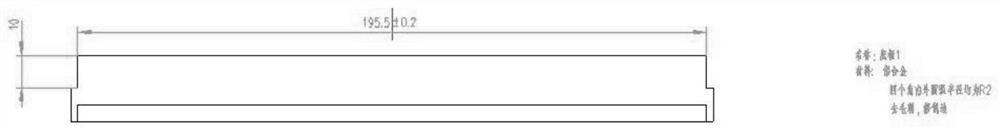

[0030] The batch assembly process device for fasteners in this embodiment is used to realize the batch assembly of screws, flat washers, and spring washers, and solve the problem of quickly assembling multiple screws, flat washers, and spring washers at one time when assembling a large number of fasteners, improving assembly efficiency and The method of quality, using this technological device invention example, can realize the assembly of 139 groups of screws, flat washers and spring washers with the same specification at most at one time. Specifically, by designing a set of pallets with screws, flat washers and spring washers, the screws, flat washers and spring washers are placed on these adsorption boards and pallet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com