Polishing equipment for computer hardware production

A computer hardware and equipment technology, applied in the field of computer hardware production, can solve problems such as potential safety hazards, hand injuries of operators, inconvenient replacement of polishing wheels for polishing equipment, etc., and achieve the effect of preventing breakage and increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

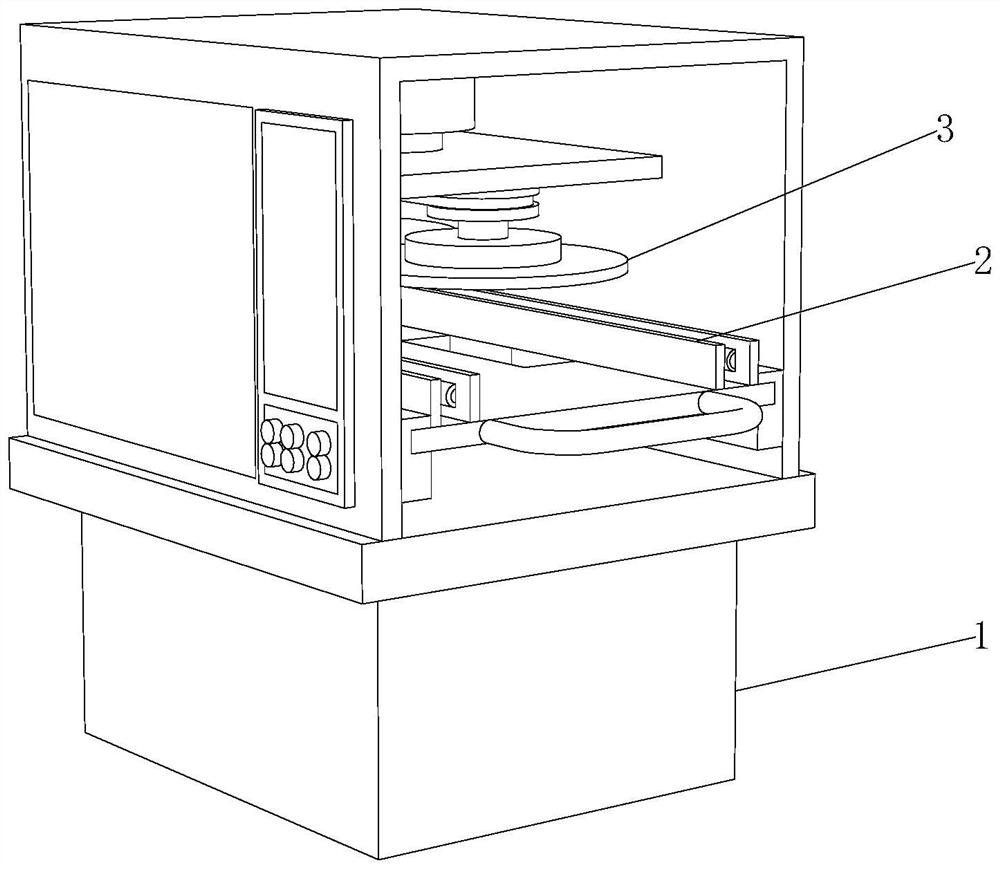

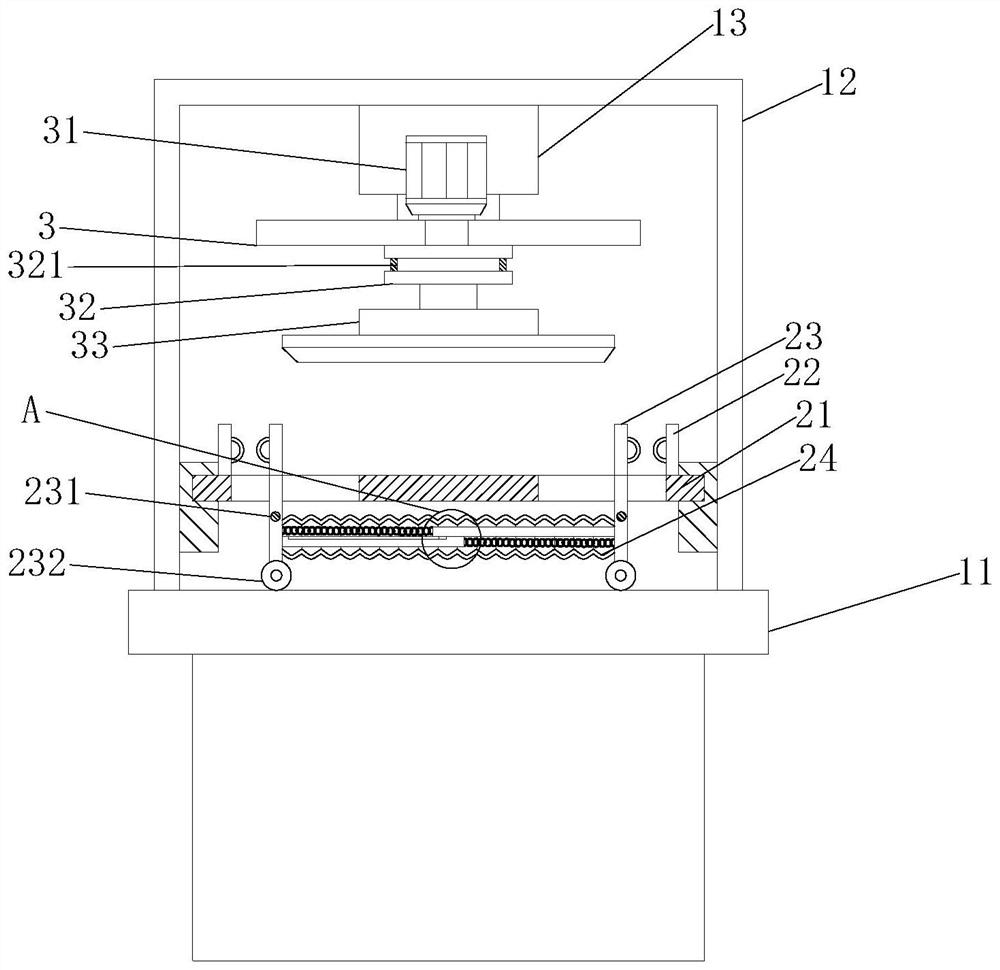

[0031] Such as Figure 1-6 As shown, the present invention provides a kind of polishing equipment that is used for computer hardware production, comprises polishing equipment main body 1, and polishing equipment main body 1 comprises polishing grinding table 11, and the upper surface of polishing grinding table 11 is fixedly installed with dustproof cover 12, prevents The top of the inner surface of the dust cover 12 is fixedly equipped with a lifting device 13, the upper surface of the polishing table 11 is provided with a mobile clamping device 2, and the lower end of the lifting device 13 is provided with a polishing wheel clamping device 3, and the mobile clamping device 2 includes Pull the moving plate 21, the fixed plate 22, the moving clamping plate 23, the elastic limit tube 24 and the soft clamping sleeve 25, the side surface of the pulling moving plate 21 is slidably connected with the inner surface of the dust cover 12, and the polishing wheel The clamping device 3 ...

Embodiment 2

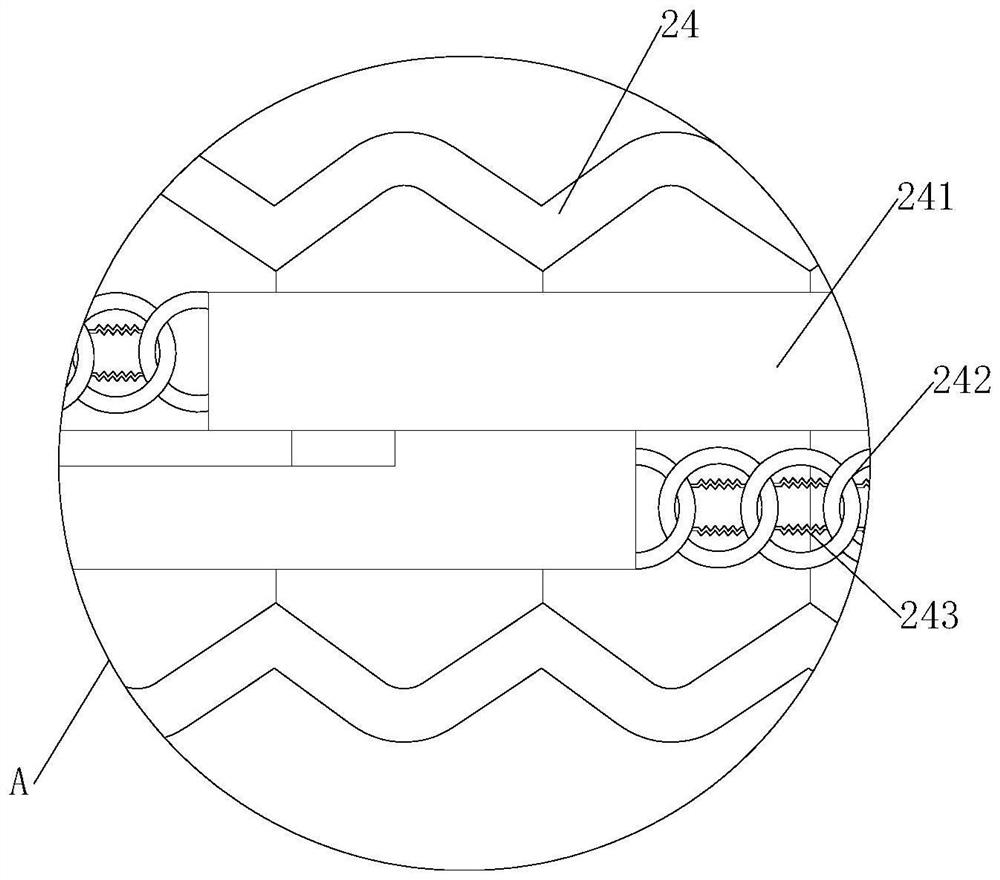

[0034] Such as Figure 1-6 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: the two ends of the elastic force limiting tube 24 are respectively fixedly connected with the outer surface of the movable clamping plate 23, and the inside of the elastic force limiting tube 24 is provided with a sliding plate 241, the two ends of the sliding plate 241 are fixedly connected with the outer surface of the movable clamping plate 23 respectively, the two ends of the sliding plate 241 are fixedly equipped with an elastic connecting ring 242, and one end of the elastic connecting ring 242 is connected with the outer surface of the movable clamping plate 23. Fixedly connected, a spring chain 243 is fixedly installed in the middle of the elastic connection ring 242 .

[0035] In this embodiment, after the computer hardware shell is placed between the movable clamping plate 23 and the fixed plate 22 to complete the replacement, the loose armrest 231...

Embodiment 3

[0037] Such as Figure 1-6 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: the two ends of the soft clamping sleeve 25 are hinged to the inner wall of the fixed plate 22, and the inner side of the soft clamping sleeve 25 is provided with an elastic extrusion ball 251, the outer surface of the elastic extrusion ball 251 is in contact with the inner surface of the soft clamping sleeve 25, and one end of the elastic extrusion ball 251 is fixedly equipped with a rubber column fixing device 252, and one end of the rubber column fixing device 252 is connected to the fixed plate 22 The inner wall surface of the rubber column fixing device 252 is fixedly connected, and a reinforcing spring rope 253 is fixedly installed in the middle of the rubber column fixing device 252 .

[0038] In this embodiment, the soft clamping sleeve 25 cooperates with the movable clamping plate 23 and the fixed plate 22 to clamp the computer hardware shell, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com