Printing equipment for printing along peripheral side surface and control method

A technique for printing equipment and a control method, which is applied to printing devices, printing, typewriters, etc., can solve the problems of poor applicability of printing equipment, and achieve the effect of convenient printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

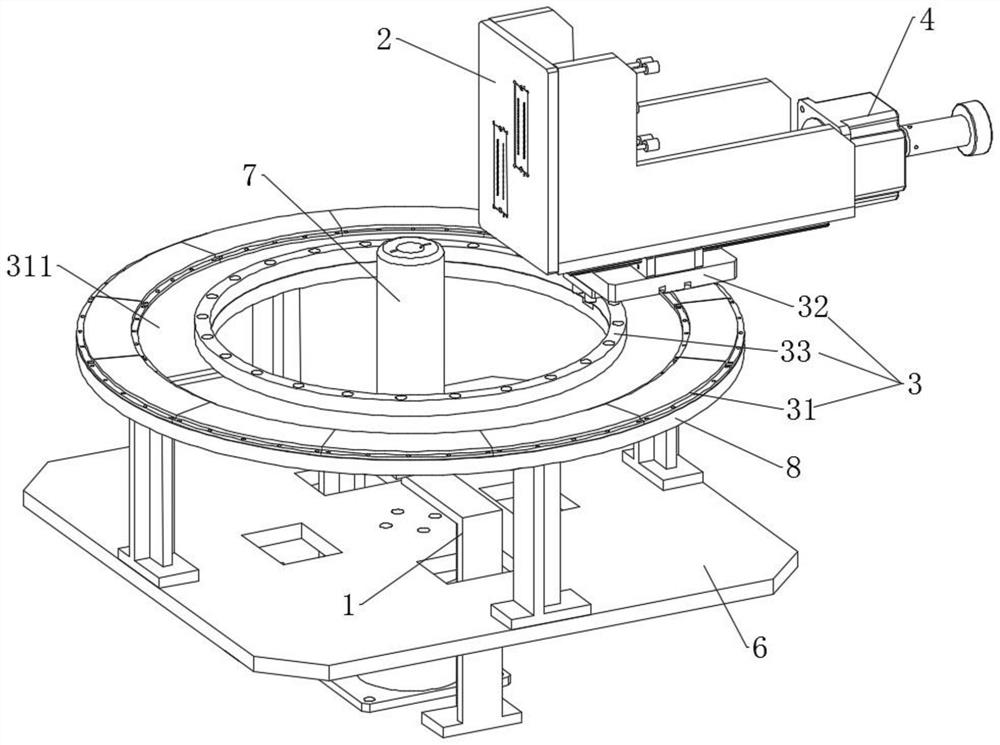

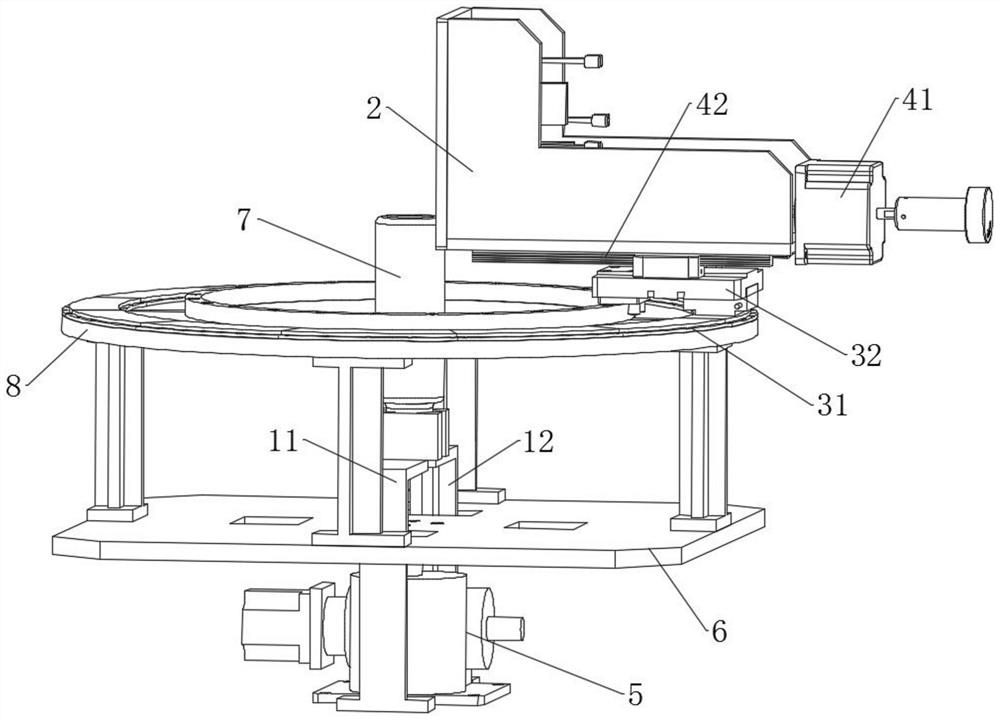

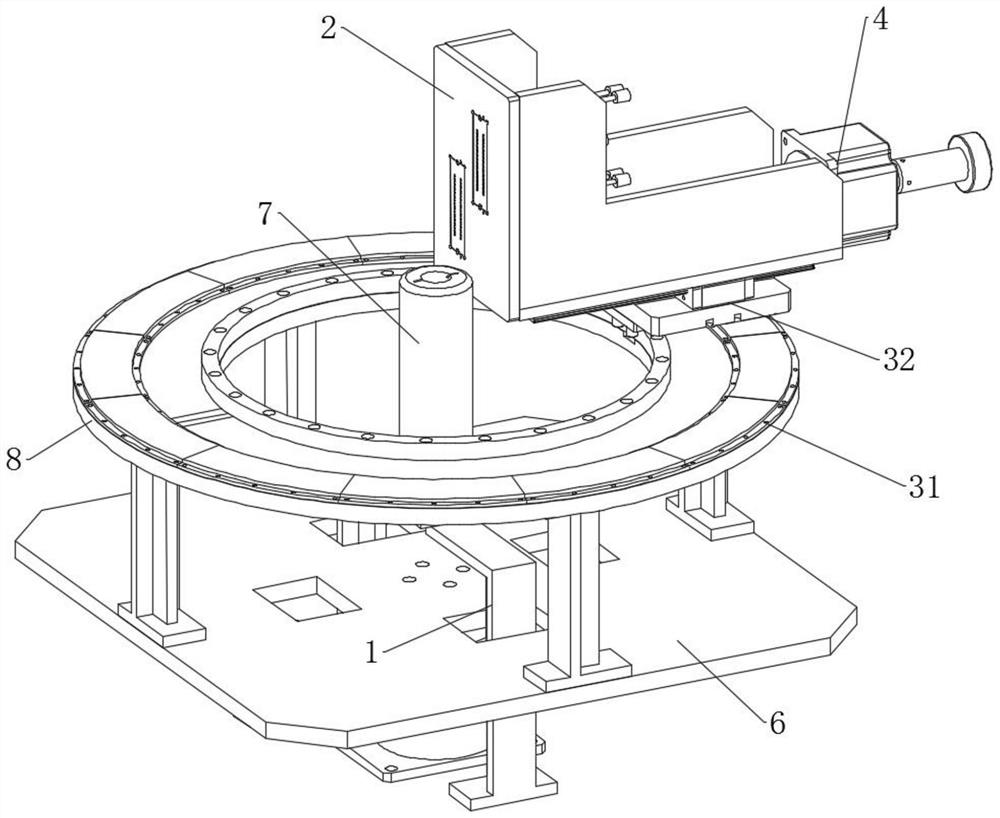

[0045] Embodiment 1 of the present invention provides a printing device for printing along the peripheral side, which is used for printing along the peripheral side of the printing medium. The printing medium can be a cylinder, a cone, a tetrahedron, etc., or a flexible material wrapped around a column Materially, a printing area is formed on the surface of the columnar body, and the printing device is suitable for printing with any proportion of the printing area. combine figure 1 As shown, specifically, the printing device includes:

[0046] Track 8, the printing medium 7 is placed on one side of the track 8, the track 8 can be a circular track 8, or an arc-shaped track 8, specifically, the shape of the track 8 can be determined according to the printing area of the printing medium 7 required to print .

[0047] The printing mechanism 2, the printing mechanism 2 is arranged on the track 8, and is used to spray the liquid in the area to be printed on the to-be-printed med...

Embodiment 2

[0080] Embodiment 2 of the present invention provides a control method for printing along the peripheral side, which is specifically used to control any one of the printing devices in Embodiment 1. Specifically, in combination with Figure 6 , the method includes:

[0081] Obtain the location information of the area to be printed on the printing medium; the area to be printed is on the side of the printing medium 7, which can be on the surrounding side covering the entire printing medium 7, or on a partial area on the side of the printing medium 7. In addition, the printing medium 7 can be a cylinder, a cone or other three-dimensional objects; and the side of the printing medium 7 can be a regular figure or an irregular figure.

[0082] Calculate the movement path of the printing carriage relative to the track according to the position information; pre-store the shape of the track 8 on the system, set a grating on the track 8, read the position of the printing mechanism 2 in t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap