Anisotropic silicon dioxide aerogel with birefringent effect and preparation method thereof

An anisotropic, silicon dioxide technology, applied in chemical instruments and methods, inorganic chemistry, silicon compounds, etc., to achieve the effect of simple process and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

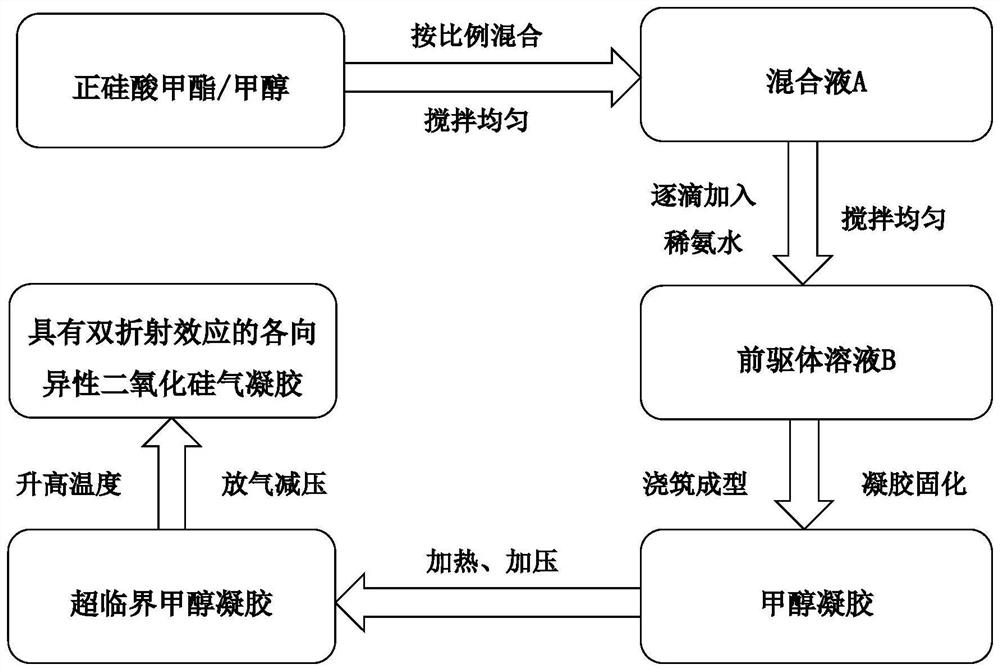

[0038] The invention provides a preparation method of anisotropic silica airgel with birefringence effect, such as figure 1 As shown, it specifically includes the following steps:

[0039] Step 1, mixing methyl orthosilicate and methanol evenly to obtain mixed solution A;

[0040] In step 1, the volume ratio of methyl orthosilicate and methanol is 10:80-100.

[0041] Step 2, add dilute ammonia water dropwise to the mixed solution A obtained in step 1, stir magnetically for 0.5-1h, and mix evenly to obtain precursor sol B;

[0042] In step 2, the concentration of dilute ammonia water is 0.003-0.005M, and the volume ratio of dilute ammonia water and methyl orthosilicate used in step 1 is 2.4:10.

[0043] Step 3, transfer the precursor sol B obtained in step 2 to a stainless steel container, the axis of the quartz tube is parallel to the axis of the stainless steel container, put a stainless steel cover on the cylindrical stainless steel container, and let it stand for 3-4d, an...

Embodiment 1

[0051] The volume ratio of methyl orthosilicate and methanol is 10:80, the concentration of dilute ammonia water is 0.004M, exhaust at a depressurization rate of 5MPa / h, and heat the supercritical drying kettle at a heating rate of 10°C / h to Silica airgel prepared after drying at 280°C.

[0052] First, mix methyl orthosilicate and methanol evenly according to the volume ratio of 10:80 to obtain mixed solution A;

[0053] Secondly, according to the volume ratio of dilute ammonia water and orthosilicate methyl ester of 2.4:10, add dilute ammonia water with a concentration of 0.004M to the mixed solution A dropwise, magnetically stir for 0.5h, and mix uniformly to obtain the precursor sol B;

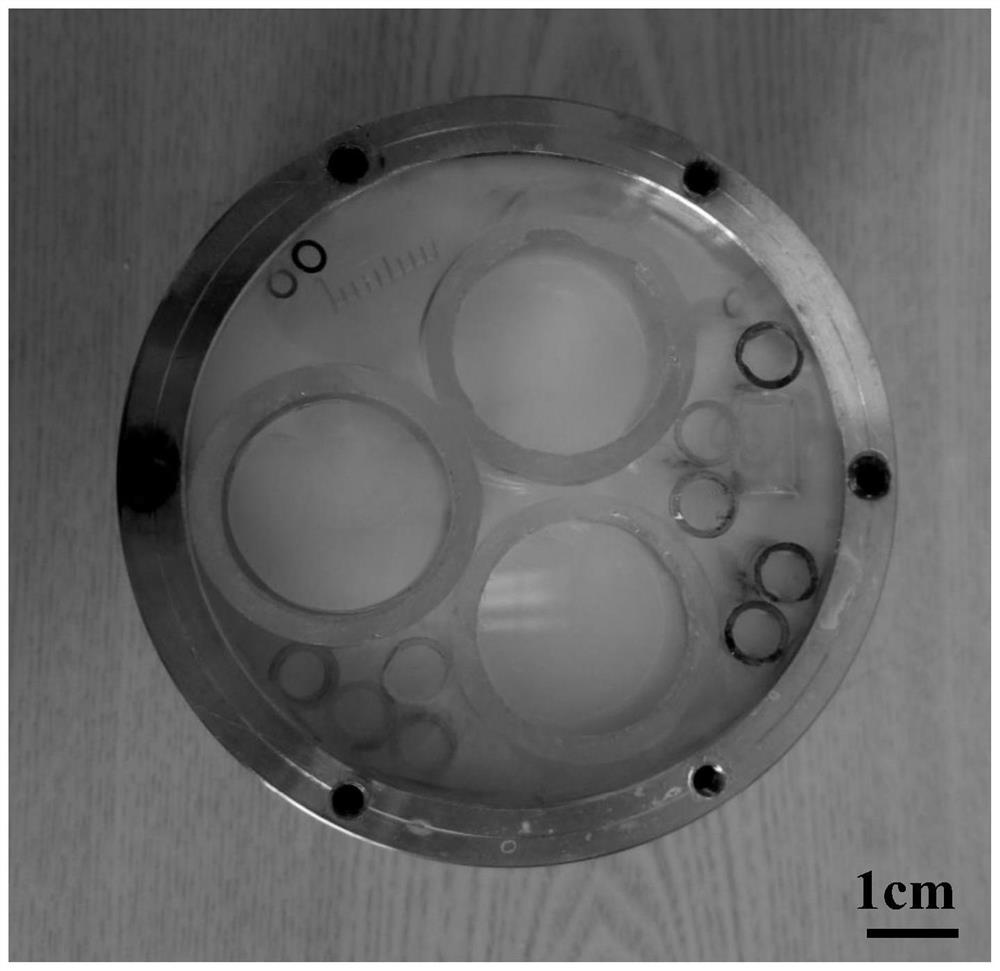

[0054] Third, transfer the precursor sol B to a stainless steel container with a quartz tube placed in advance. The inner diameter of the stainless steel container is 80 mm, the inner height is 50 mm, and the wall thickness is 5 mm. The inner diameter of the quartz tube is 8 mm, and the len...

Embodiment 2

[0058] The volume ratio of methyl orthosilicate and methanol is 10:100, the concentration of dilute ammonia water is 0.004M, exhaust at a depressurization rate of 5MPa / h, and heat the supercritical drying kettle at a heating rate of 10°C / h to Silica airgel prepared after drying at 280°C.

[0059] First, mix methyl orthosilicate and methanol evenly according to the volume ratio of 10:100 to obtain mixed solution A;

[0060] Secondly, according to the volume ratio of dilute ammonia water and orthosilicate methyl ester of 2.4:10, add dilute ammonia water with a concentration of 0.004M to the mixed solution A dropwise, magnetically stir for 0.5h, and mix uniformly to obtain the precursor sol B;

[0061] Third, transfer the precursor sol B to a stainless steel container with a quartz tube placed in advance. The inner diameter of the stainless steel container is 80 mm, the inner height is 50 mm, and the wall thickness is 5 mm. The inner diameter of the quartz tube is 8 mm, and the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap