Chip base ceramic local metallization device and process

A chip base and metallization technology, which is applied to the ceramic local metallization device and process field of the chip base, can solve the problems of scalding staff, affecting heating efficiency, slow heat, etc., and achieves rapid melting and good heating effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

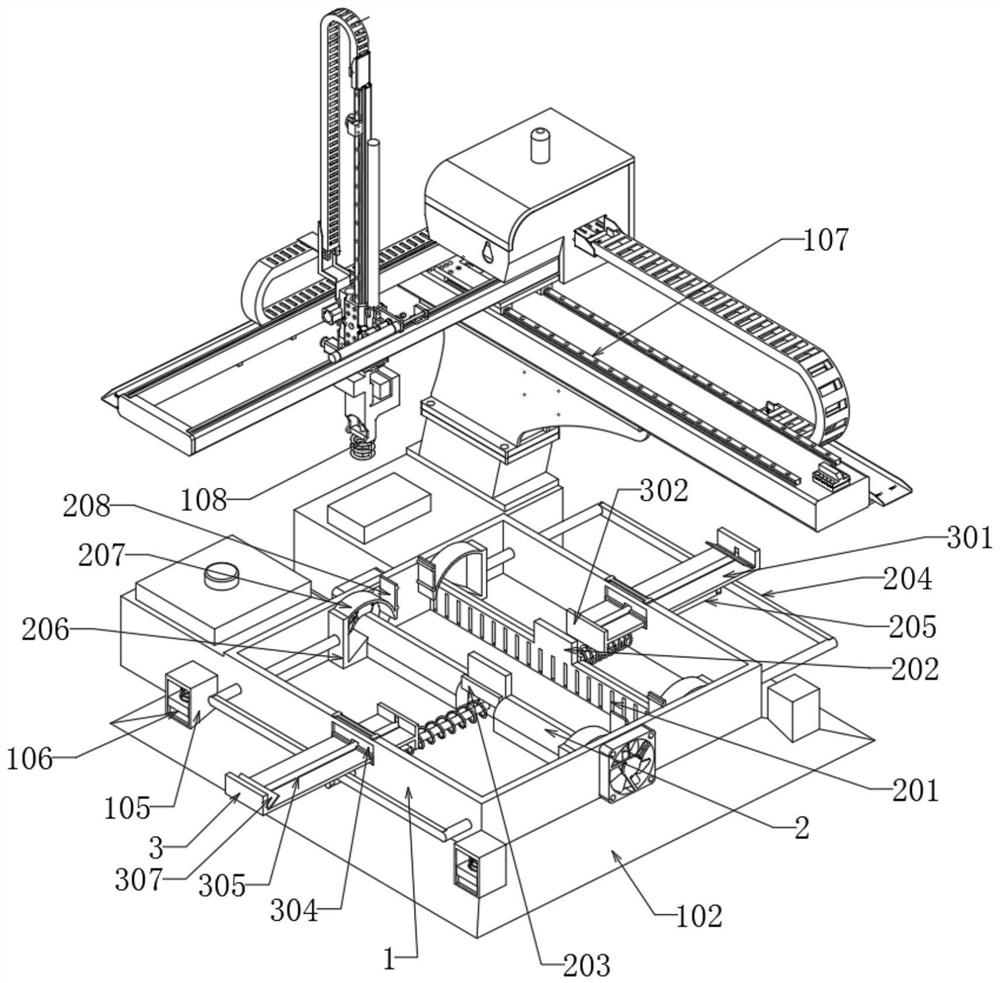

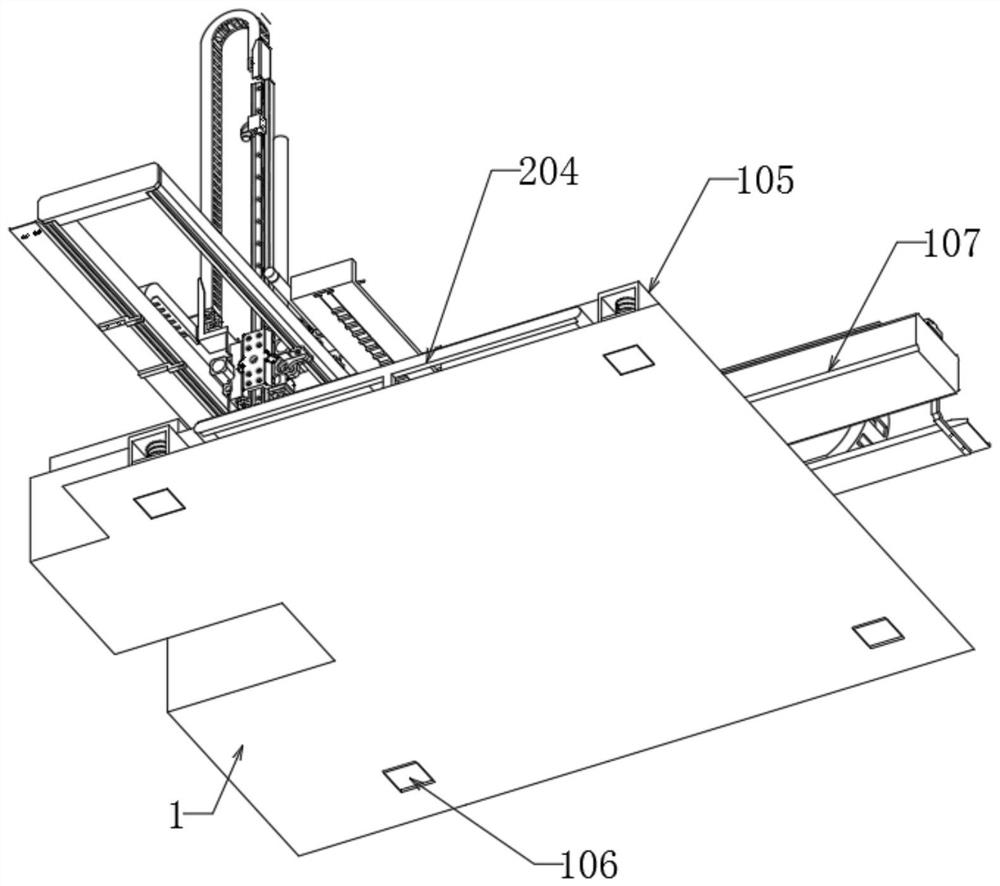

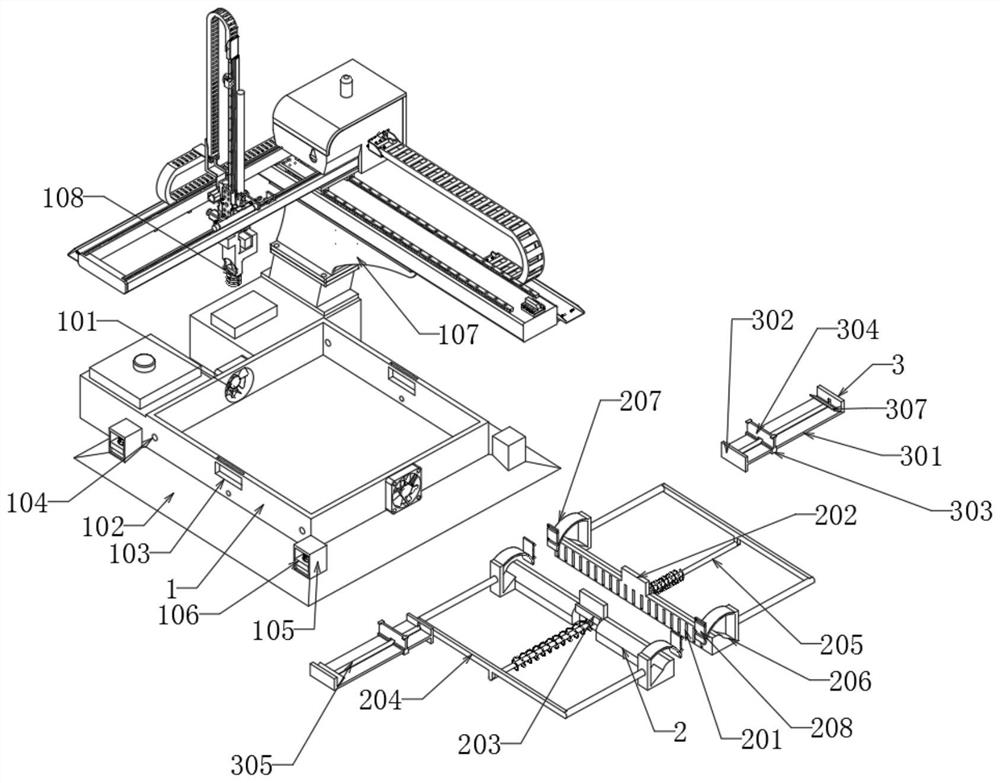

[0038] Example: Please refer to Figure 1 to Figure 8 :

[0039] The present invention proposes a chip base ceramic local metallization device and process, comprising: a main body 1; the main body 1 is a rectangular structure, the inside of the main body 1 is a rectangular structure, and a heating plate is installed at the inner bottom of the main body 1 for heating the base And the metallized material is heated, the side of the main body 1 is provided with a heating controller, and the top of the heating controller is provided with a heating control knob, which is convenient to control the temperature adjustment. A mounting block 105 is provided at the corner position respectively, and the inside of the mounting block 105 is equipped with a moving block 106 through a spring. The moving block 106 is an L-shaped structure, which can continuously receive spring power to move downwards inside the mounting block 105, and the moving block 106 There is a rubber plate at the bottom,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com