Cross-blowing oxidizing furnace device

An oxidation furnace and side blowing technology, applied in the chemical characteristics of fibers, textiles and papermaking, etc., can solve the problems of pre-oxidation wire shaking up and down, affecting the performance of carbon fiber, unfavorable temperature uniformity, etc. The effect of uniform temperature in the furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

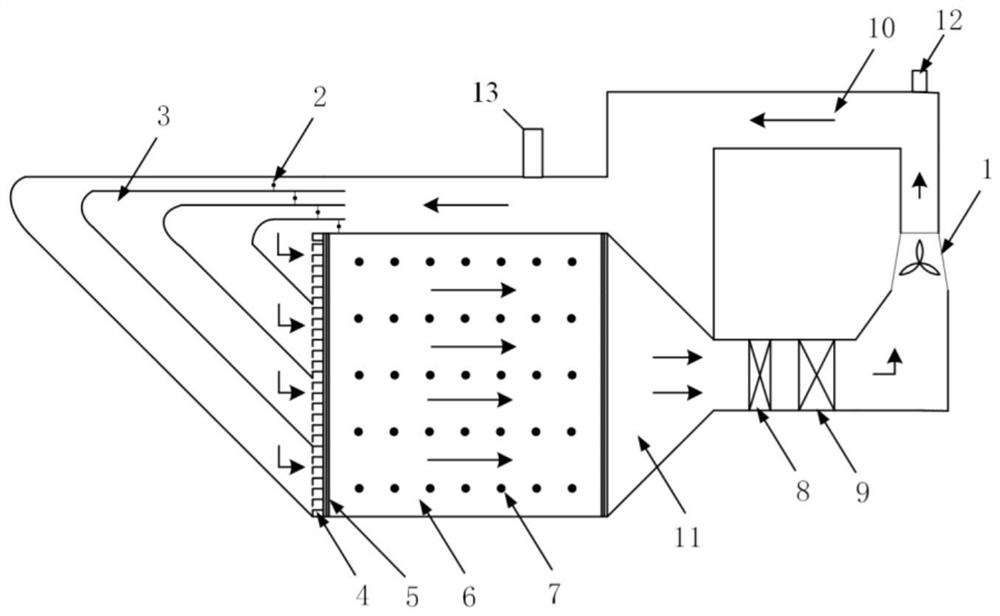

[0033] like figure 1 The side-blown oxidation furnace device shown in the figure includes oxidation furnace wire passage 6, return air duct 11, fan 1, circulating air duct 10 and multi-channel distributor 3, wherein:

[0034] The fiber tow undergoes oxidation reaction in the wire passage 6 of the oxidation furnace, and passes through the length direction of the wire passage 6 of the oxidation furnace, such as figure 1 As shown in , several pre-oxygen wires 7 are evenly arranged in the wire passage 6 of the oxidation furnace. Since the pre-oxidation wires 7 run along the length direction of the wire passage 6 of the oxidation furnace, the wire bundles are vertically Its own gravity will bend to a certain extent. The traditional top-to-bottom blowing method will increase the force of the tow in the vertical direction, so it will increase the jitter in the up and down direction to a certain extent, resulting in the phenomenon of wiping. , in the embodiment of the present inventi...

Embodiment 2

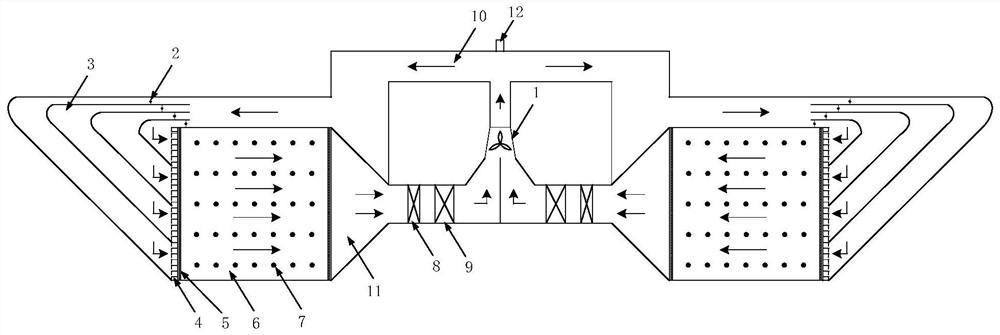

[0048] In the second embodiment of the present invention, as figure 2 As shown in the figure, the side-blown oxidation furnace device is symmetrically arranged, and the device is symmetrically arranged on the line where the initial wind direction of the fan 1 is located, so as to realize the common use of the fan 1 . Through the symmetrical arrangement, a part of the circulating air duct 10 is shared, which saves the usage of the fan 1, and also realizes the simultaneous production of multiple groups of tows under uniform working conditions, which improves the quality and production efficiency of carbon fiber production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com