Rapid treatment device capable of refining contaminated soil

A soil pollution and rapid technology, applied in the field of soil pollution control, can solve the problems of inability to refine the soil, slow treatment process, etc., and achieve the effect of speeding up the screening progress, speeding up the restoration process, and speeding up the soil restoration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

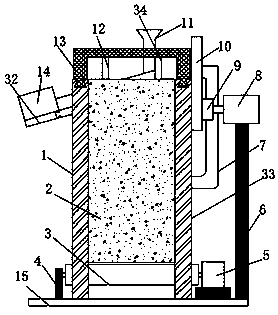

[0031] A rapid control device for fine soil pollution, comprising a left frame 1, a rotating rod 10, a feeding port 11, a moving frame 13, a carrying platform 32 and a right frame 33, the inner side of the left frame 1 and the left side of the dust-proof baffle A2 Fixedly connected, the right side of the dust-proof baffle A2 is fixedly connected with the inner side of the right frame 33, the left frame 1 and the upper middle of the right frame 33 are provided with a dust-proof baffle B34, and the bottom ends of the left frame 1 and the right frame 33 are both Fixedly connected with the upper surface of the base 15, the upper ends of the left frame 1 and the right frame 33 are provided with a wedge-shaped moving groove A28, and the inside of the wedge-shaped moving groove A28 is movably socketed with a wedge-shaped block A29, and the upper end of the wedge-shaped block A29 is connected with the lower ends of the left and right sides of the moving frame 13. fixed connection;

[...

Embodiment 2

[0034] Embodiment 2: the difference based on Embodiment 1 is;

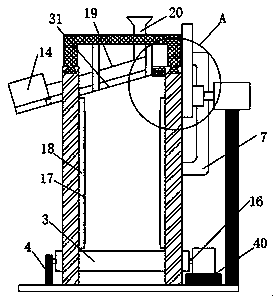

[0035] The inner side of the dust-proof baffle B34 is fixedly connected to the outer side of the liquid medicine storage tank 18, and the outer surface of the liquid medicine storage tank 18 is fixedly installed with an atomizing nozzle 17, and the outer side of the liquid medicine storage tank 18 is connected to the inlet. One end of the drug tube 7 is fixedly connected, the other end of the drug inlet tube 7 is fixedly connected to the middle part of the drug pumping tube 22, the right end of the drug pumping tube 22 is fixedly connected to the upper end of the external pipeline 21, and the drug pumping tube 22 is movably sleeved with a drug pumping rod 24. The right side of the medicine rod 24 is fixedly connected to the left side of the piston 23, and the right side of the medicine rod 24 is fixedly connected to the right side of the moving frame 13;

[0036] When the present invention is in use, the soil is s...

Embodiment 3

[0037] Embodiment 3: the difference based on embodiment 1 and 2 is;

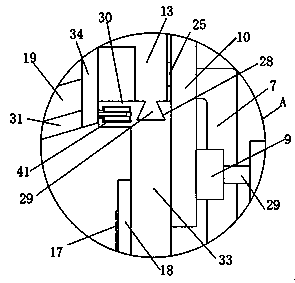

[0038] The left side of the upper end of the right frame 33 is provided with a limiting block 30, the inside of the limiting block 30 is provided with a limiting groove 41, the lower end of the right side of the support column B34 is fixedly connected with the limiting rod 42, and the right end of the limiting rod 42 is fixedly connected with the roller shaft 43, and the roller shaft 43 is up and down. Roller wheels 44 are movably socketed at both ends, and the rollers 44 are movably socketed inside the limiting groove 41;

[0039] During the use of the present invention, the moving frame 13 moves left and right, in order to prevent it from shaking up and down when moving, thereby driving the shaking of the material on it, shaking it out of the grading screen 47, thereby setting a limiting frame at its bottom. The rod 42 rolls in the defined groove 41 through the roller 44 at the bottom of the rod 42, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com