Method for processing microscale dust in tail gas of calcium carbide furnace

A technology of calcium carbide furnace exhaust gas and treatment method, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve problems such as easy blockage of pipes and equipment, small particle size dust, and potential safety hazards, and achieves the goal of less equipment, less The effect of less pollution and improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

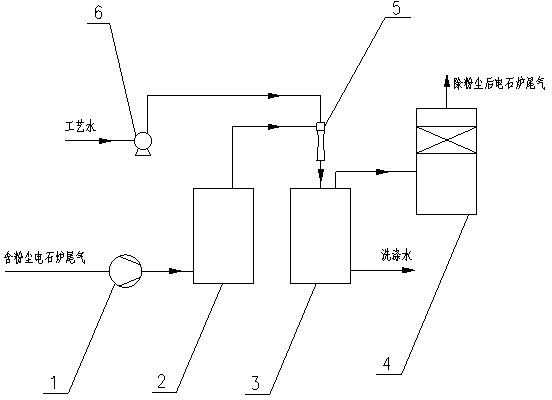

[0018] Refer to attached figure 1 , the present embodiment comprises a compressor 1, a buffer tank 2, a wet dust collector, a gas-liquid separator 3 and a filter 4 connected in sequence, and the above equipment forms a deep dust removal system in the purification process of the calcium carbide furnace tail gas; After the pressure is increased, the dust-containing calcium carbide furnace tail gas passes through the buffer tank and then enters the wet dust collector for dust removal. The process water enters the wet dust collector after passing through the plunger pump 6, and the gas-liquid mixture of the calcium carbide furnace tail gas exiting the wet dust collector is separated by the gas-liquid separator. The dusty water droplets are filtered through the filter to remove the fine dusty droplets that have not been separated, and then the dust-removed calcium carbide furnace tail gas is sent to the deep dust removal system.

[0019] Another embodiment is different in that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com