Intelligent installation method for large oil and gas module pipeline parts

An installation method and parts technology are applied in the field of intelligent assembly of large oil and gas module pipeline parts, which can solve the problems of low pipeline installation efficiency and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in detail:

[0020] Below are specific embodiments of the present invention, and technical scheme of the present invention is further described:

[0021] Step 1. Import the main pipeline model of the large-scale oil and gas module into the CATIA software, determine the installation position of the pipeline components in the main pipeline model according to the design and installation plan of the pipeline components, and follow the sequence from the beginning end to the end end in the main pipeline model Number the pipeline components, for example: the numbering rules described can be 1, 2, 3, ....

[0022] Step 2: Establish a pipeline parts model library in CATIA software, and store the pipeline parts in the pipeline parts model library in sequence according to the serial number.

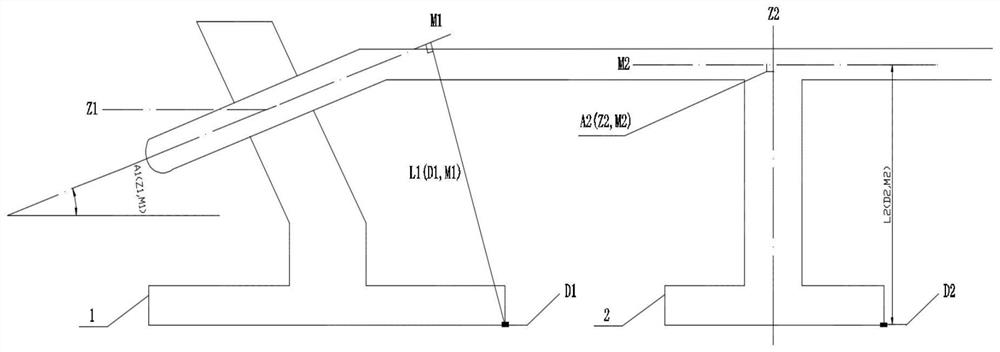

[0023] Step 3: Construct the installation features between the pipeline main body mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com