Contour lower section design method and tire

A cross-section design and contour technology, applied in special tires, tire parts, design optimization/simulation, etc., can solve the problem of not fully meeting the performance and safety requirements of run-flat safety tires, and achieve the goal of reducing roundness. The effect of approaching, preventing rollover, and increasing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

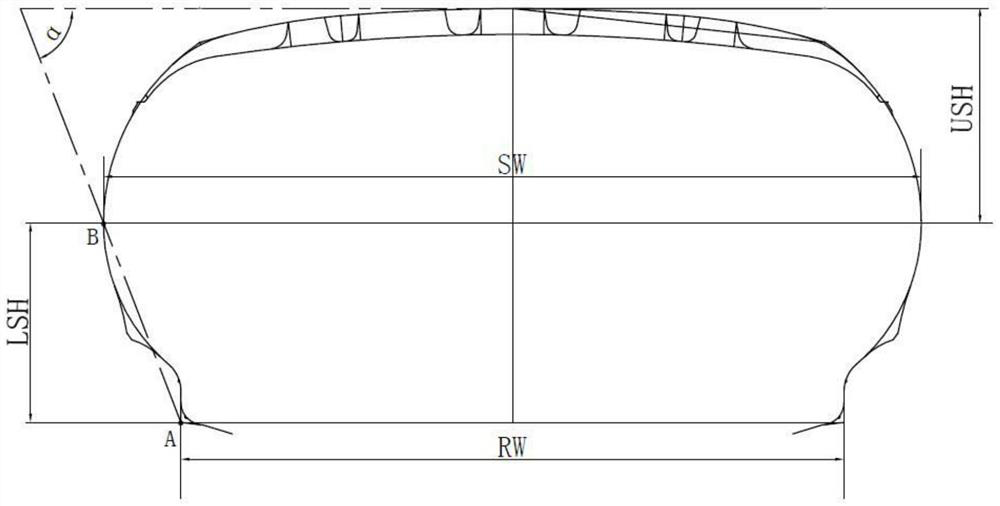

[0040] Step 1, establish an initial tire profile model according to the selected tire model 225 / 55R17;

[0041]Step 2. According to the outer diameter D of the tire, the diameter of the rim and the diameter d, the section height SH=1 / 2(D-d) is obtained, and the lower section height LSH and the upper section height USH of the profile are adjusted to make LSH / USH=1.05;

[0042] Step 3. Adjust the contour width RW to 191mm;

[0043] Step 4. Adjust the profile section width SW to 238mm;

[0044] Step 5. Construct the functional relationship of the contour parameters according to the test data in steps 2 to 4, and verify by the formula tanα=2LSH / (SW-RW), and the calculated value of α is 68.8°.

Embodiment 2

[0046] Step 1, establish an initial tire profile model according to the selected tire model 215 / 65R16;

[0047] Step 2. According to the tire outer diameter D, rim diameter and diameter d, obtain the section height SH=1 / 2(D-d), adjust the profile lower section height LSH and upper section height USH, so that LSH / USH=1.08;

[0048] Step 3. Adjust the contour width RW to 185mm;

[0049] Step 4, adjust the profile section width SW to 226mm;

[0050] Step 5. Construct the functional relationship of the contour parameters according to the test data in steps 2 to 4, and verify by the formula tanα=2LSH / (SW-RW), and the calculated value of α is 74.1°.

Embodiment 2 and comparative example 2

[0061] Table 1 embodiment 2 and comparative example 2 driving force factor and braking force factor test table

[0062] Test items Example 2 Comparative example 2 Driving radial force / N 3445.6 3489.7 Maximum longitudinal force when driving / N 4976.2 4876.4 driving force factor 1.44 1.40 Braking radial force / N 3449.9 3492.6 Maximum longitudinal force during braking / N -4195.3 -4176.3 braking force factor 1.22 1.20

[0063] Through the test comparison of Example 2 and Comparative Example 2, it can be seen that the test result of Example 2 is better than that of Comparative Example 2. It can be seen that the design of the over-large width RW is not good for the traction performance, and it will also increase The pressure on the bead causes the bead to break and cause damage to the rim.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com