Rapid cooling device and cooling process for wire and cable production

A rapid cooling, wire and cable technology, used in cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems that affect the production quality of wires and cables, the uneven surface of the insulating layer, and affect the cooling effect of cables, etc., to improve the cooling effect. , Improve the service life, the overall design is ingenious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

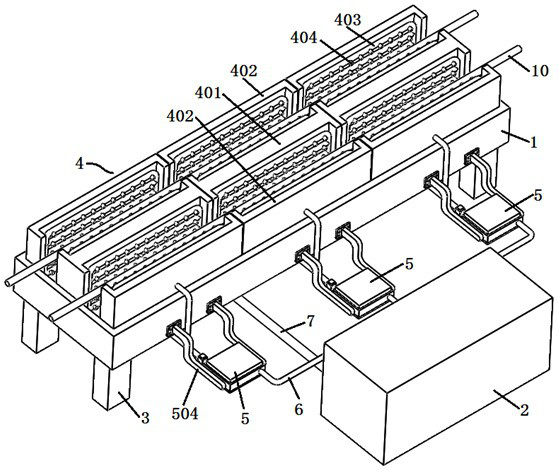

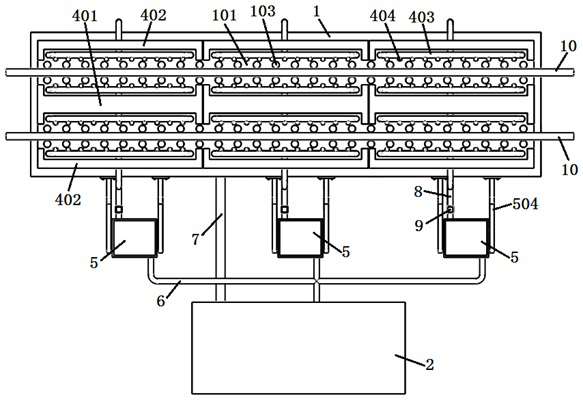

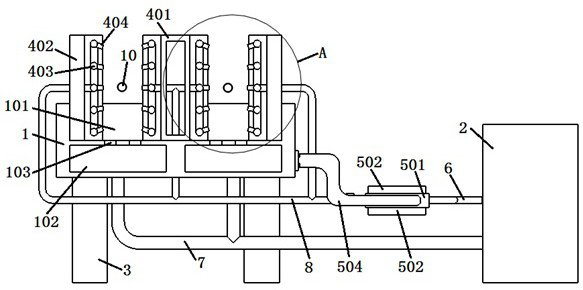

[0026] see Figure 1-8 , a rapid cooling device for wire and cable production in this embodiment includes a support platform 1 and a water tank 2, and a high-pressure pump is correspondingly installed in the water tank 2. A plurality of sets of cooling mechanisms 4 are correspondingly installed on the support platform 1 and distributed at intervals in the transverse direction, and two adjacent groups of cooling mechanisms 4 are closely connected. The cooling mechanism 4 includes two side mounting plates 402 located on both sides and a plurality of middle mounting plates 401 located in the middle, and the side mounting plates 402 and the middle mounting plates 401 are distributed at equal distances in the longitudinal direction. Both sides of the middle mounting plate 401 are correspondingly equipped with fixed water pipes 403, and the inner side of the side mounting plate 402 is also correspondingly equipped with fixed water pipes 403, and each fixed water pipe 403 is correspo...

Embodiment 2

[0032] A rapid cooling process for wire and cable production in this embodiment adopts the rapid cooling device described in Embodiment 1, which specifically includes the following steps: sending cooling water to the fixed water pipes 403 of multiple groups of cooling mechanisms 4 through the water tank 2, and The temperature of the cooling water input to the cooling mechanism 4 is controlled by using two semiconductor cooling fins 502 on the water cooling mechanism 5 corresponding to each group of cooling mechanisms 4, so that the cooling water temperature of multiple groups of cooling mechanisms 4 decreases sequentially from left to right. Then the multi-strand cables 10 are slowly passed horizontally from left to right between the two fixed water pipes 403 facing each other in multiple groups of cooling mechanisms 4, and the cooling water ejected from the high-pressure nozzle 404 on the fixed water pipes 403 is used to cool it. Can.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap