High-voltage cable assembly for new energy automobile

A new energy vehicle and cable assembly technology, applied in vehicle parts, cable joints, electrical components, etc., can solve problems such as connectors not having locking functions, potential safety hazards, and mis-separation of cables, so as to avoid safety accidents and ensure Smoothness, the effect of avoiding false separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

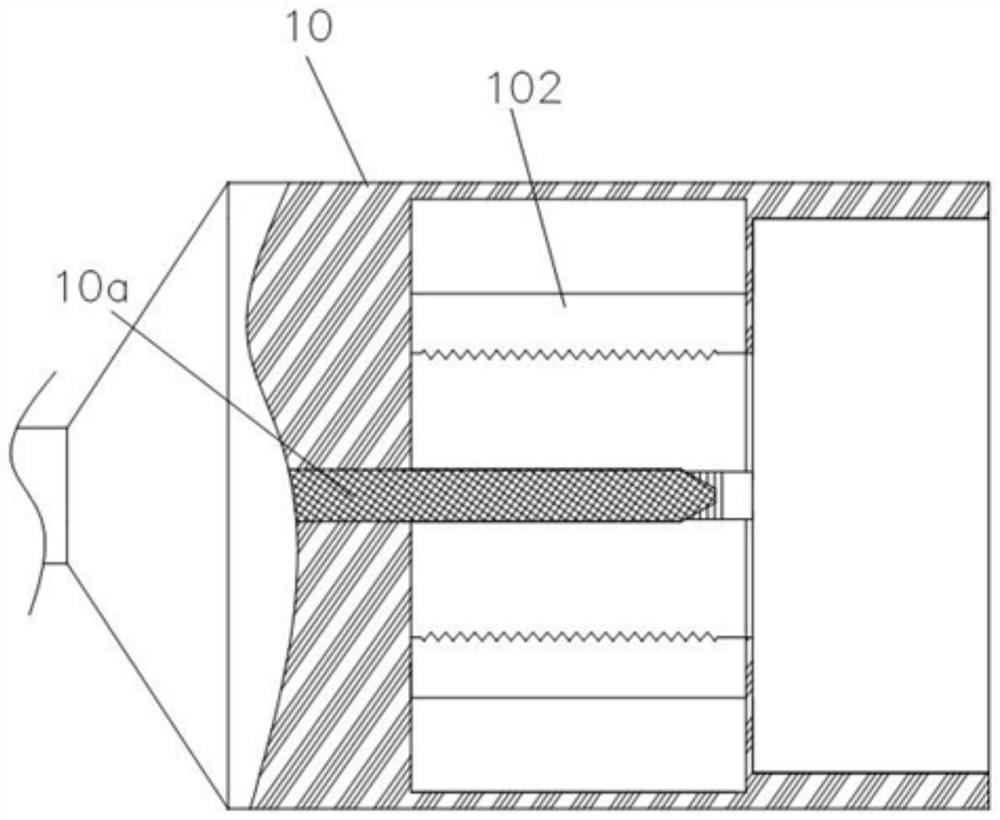

[0034] The present invention provides a high-voltage cable assembly for new energy vehicles. As a specific implementation, refer to Figure 1-Figure 3 , as a specific implementation, it includes a connector 1, the connector 1 includes a first plug 10 and a second plug 11 for plug connection, the first plug 10 includes a plug cavity 101, the second The plug 11 is provided with a plug-in post 110 mated with the plug-in cavity 101, and a first conductive member 111 is arranged in the plug-in post 110, and the plug-in post 110 is configured with at least one first rotating shaft 112, so The rotating shaft 112 is provided with a first gear 113, and the insertion column 110 is provided with an accommodating cavity 1101 around the first conductive member 111, the accommodating cavity 1101 is filled with electromagnetic fluid, and the first rotating shaft 112 extending into the accommodating chamber 1101 is provided with a damping member 114; the inner wall of the socket chamber 101 i...

Embodiment 2

[0037] The present invention provides a high-voltage cable assembly for new energy vehicles. As a specific implementation, refer to Figure 4-Figure 8 , as a specific implementation, the difference between the second embodiment and the first embodiment is that: the specific structure of the connection assembly 102 is: the connection assembly 102 includes a plurality of second rotating shafts that are rotatably arranged in the insertion cavity 101 103. The second gear 104 arranged on the second rotating shaft 103 and the ratchet 105 provided in one-to-one correspondence with the second gear 104, and the outer peripheral surface of the second gear 104 is also equipped with The ratchet surface 1041 that the pawl 105 matches.

[0038] Specifically, the working principle of the connection assembly is: when the first plug 10 and the second plug 11 are plugged in from the separated state, the first gear 113 is meshed with the second gear 104, and since the end of the first shaft is p...

Embodiment 3

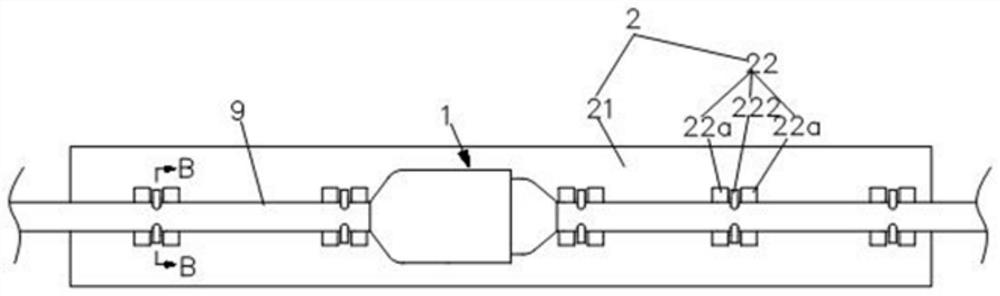

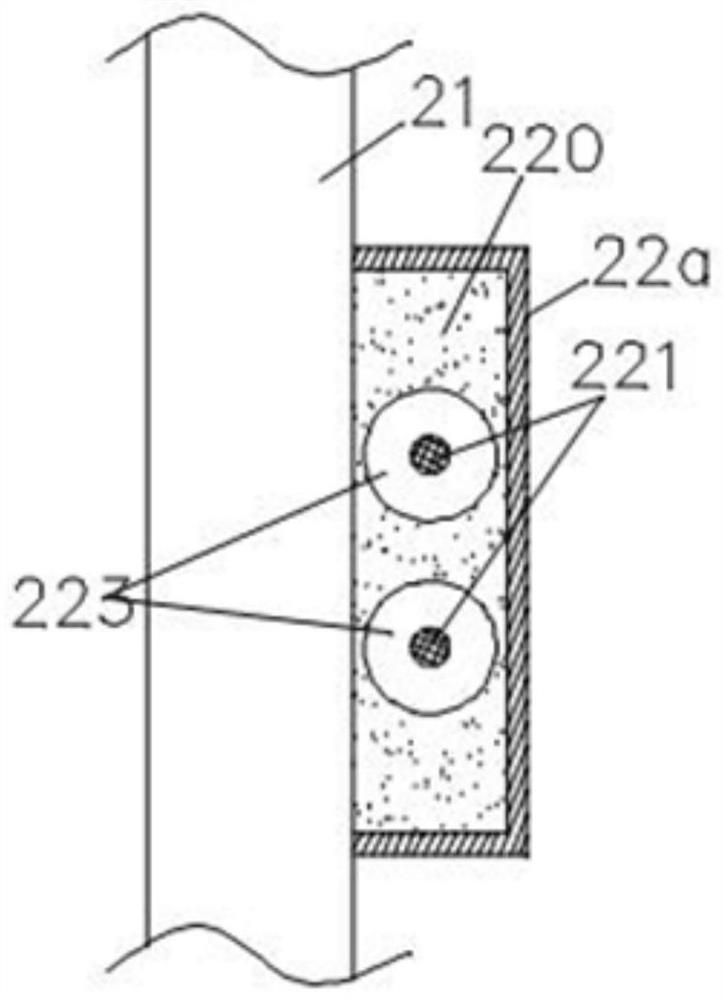

[0051] The present invention provides a high-voltage cable assembly for new energy vehicles. As a specific implementation mode, it differs from Example 2 in that reference Figure 9 , Figure 10 , as a further improvement, the present invention also includes a fixing frame 2, the cable fixing frame includes a fixing plate 21 and a plurality of fixing clips 22 arranged at intervals on the spacer plate, and between two adjacent fixing clips 22 The distance is adapted to the length of the connector, and the length of the connector is the dimension when the first plug and the second plug of the connector are plugged together.

[0052] Specifically, refer to figure 1 , in use, the fixing plate 21 is fixed on the vehicle body, and the cable 9 is fixed by the fixing clip 22, by setting the distance between two adjacent fixing clips to match the length of the connector, wherein the adjacent The distance between the two fixing clips is L1, the length of the connector is L2, then L1=(...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com