Integrated tuyere for converter

An integrated and tuyere technology, applied in the manufacture of converters, etc., can solve problems such as inability to ensure gas flow, ring-shaped interval flattening, and obstruction of converter operation, so as to improve operating efficiency, suppress the reduction of gas flow, and simplify the structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

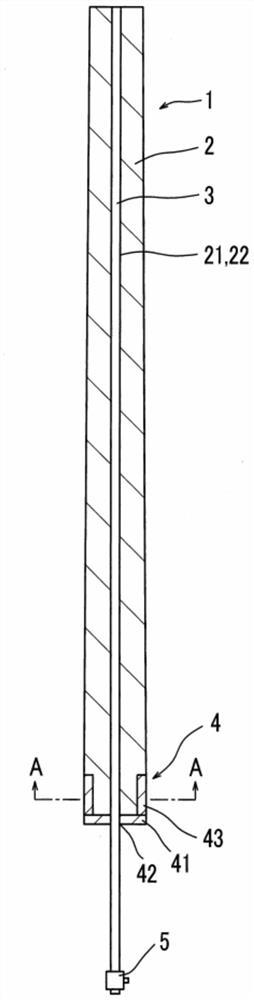

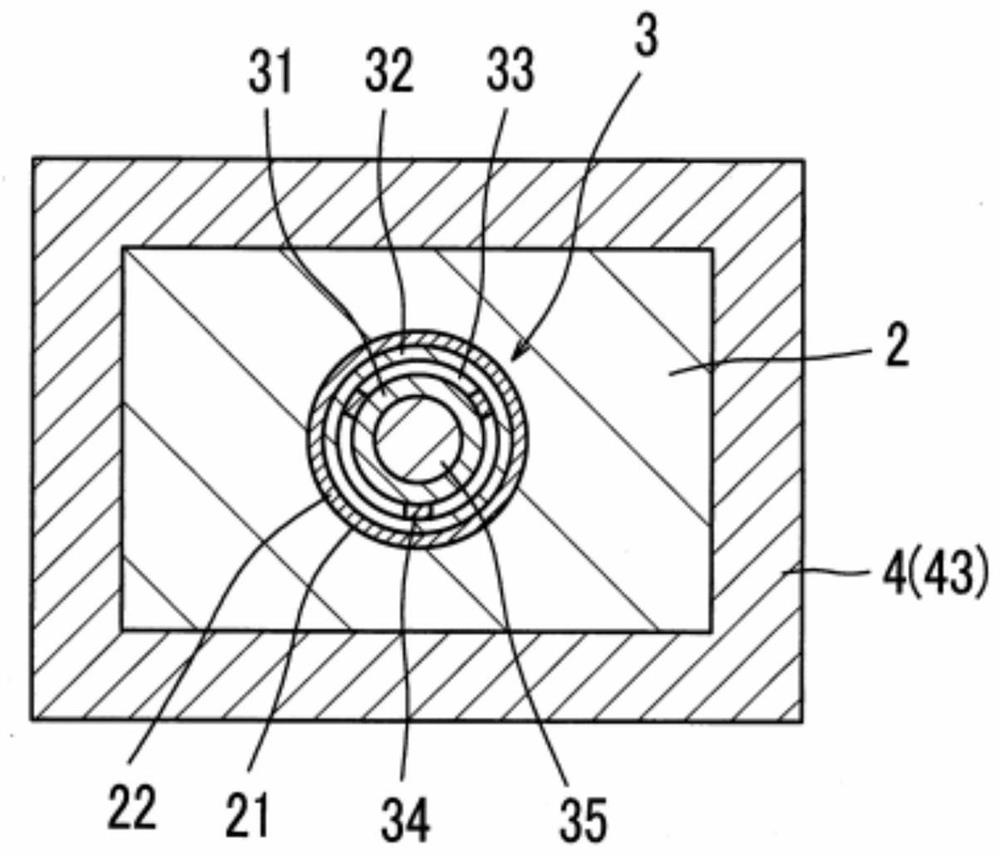

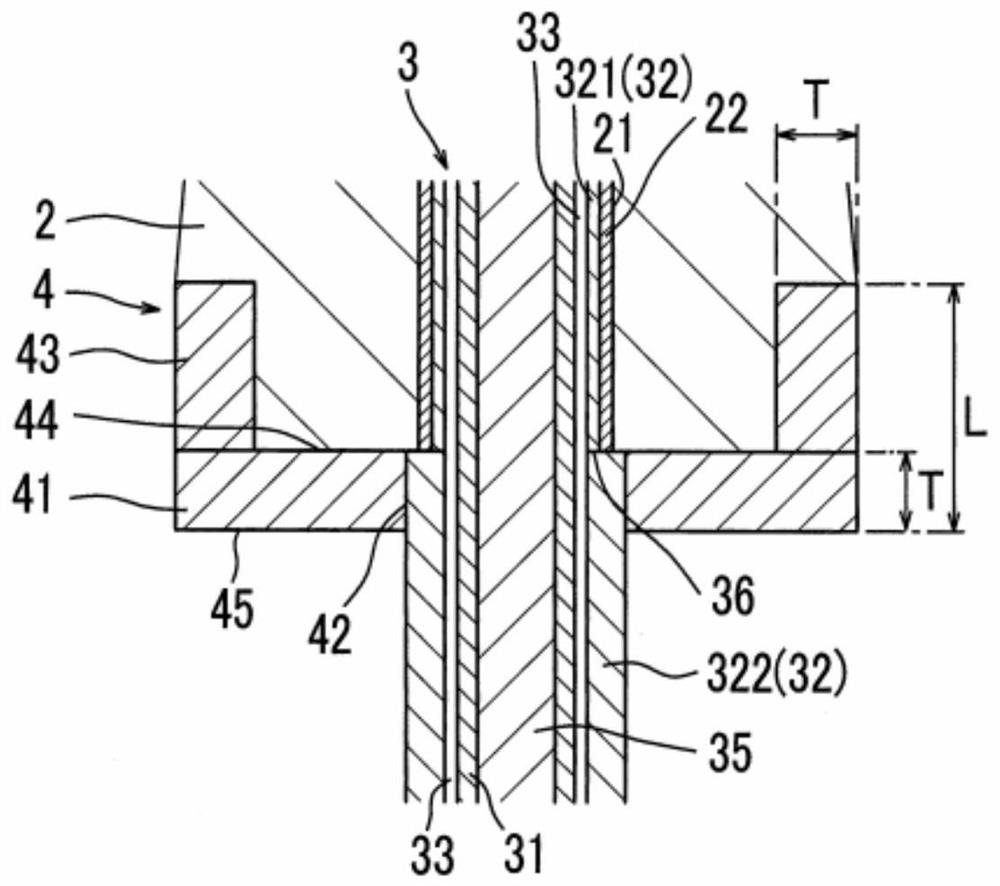

[0062] Table 1 shows that there are Figure 1 to Figure 4 In the illustrated embodiment of the integrated tuyere for the converter, the thickness T of the metal shell 4, the length L of the metal shell 4, and the thickness of the lower outer tube 322 of the double-layer metal tube 3 are different conditions, and the converters are respectively tested. The result of the handling test with the integrated tuyere. In addition, the material of the metal shell 4 is SS400, and the material of the double-layer metal tube 3 is SUS304 for the inner tube 31 and the upper outer tube 321 , and STKM for the lower outer tube 322 .

[0063] In the transportation test, the following operation was repeated 5 times, that is, the double-layer metal piping 3 protruding from the bottom plate 41 of the metal shell 4 of the integrated tuyere for the converter was lifted from the bottom plate 41 of the metal shell 4 by a crane. The position of 1 / 3 of the full length of the protruding part is kept horiz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com