Large-broken-width low-flat tire

A flat tire technology, applied to tire components, tire tread/tread pattern, vehicle parts, etc., can solve problems such as tire wear, uneven tire ground pressure distribution, overhead center of tire shoulders, etc., to increase ground contact The effect of reducing the area, reducing the force, and optimizing the distribution of ground pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

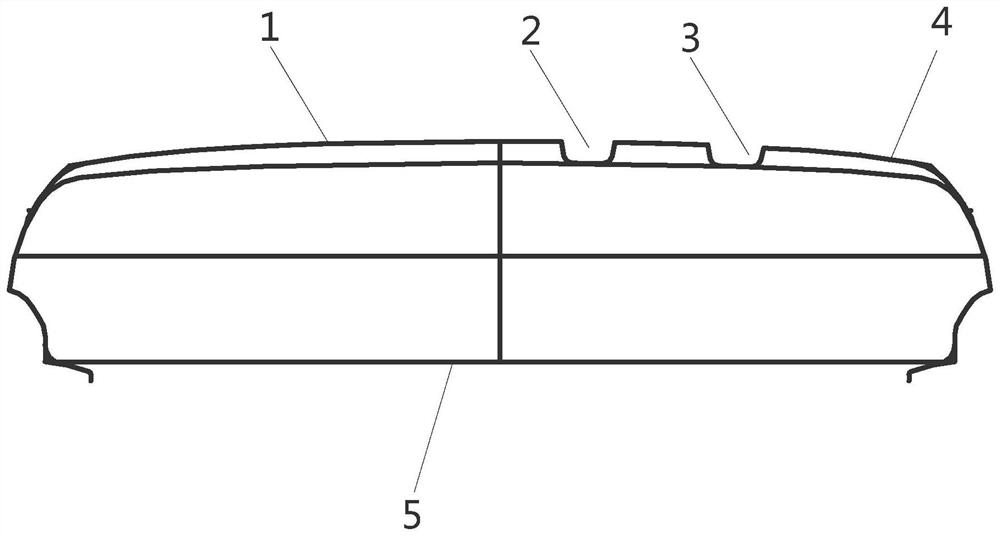

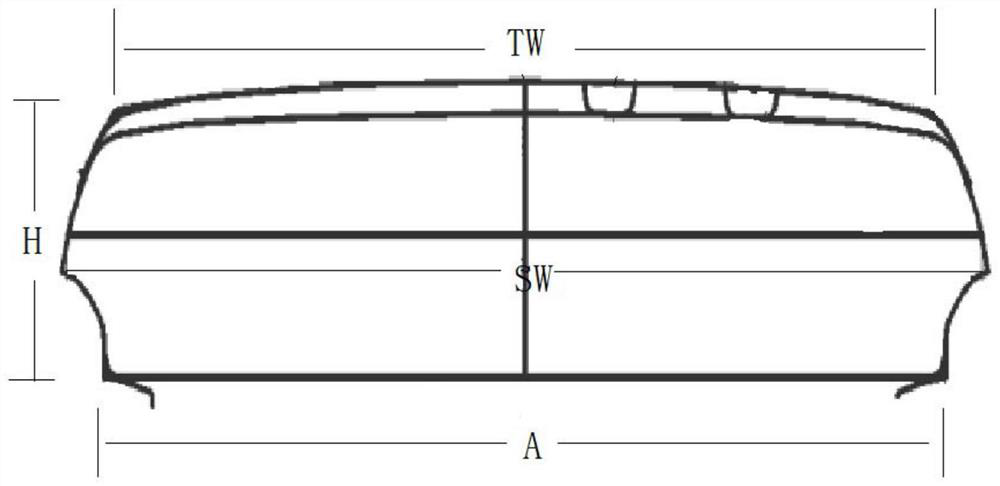

[0023] see Figure 1-Figure 4 , in an embodiment of the present invention, a tire with a large broken width and low profile includes a rim 5 and a crown 1, shoulders 4 are provided on both sides of the crown 1, and the middle part of the side of the crown 1 away from the rim 5 is provided There is a main groove 2, and a secondary groove 3 is provided on the side of the tire crown 1 away from the rim 5, and a running surface is provided on the outside of the tire crown 1;

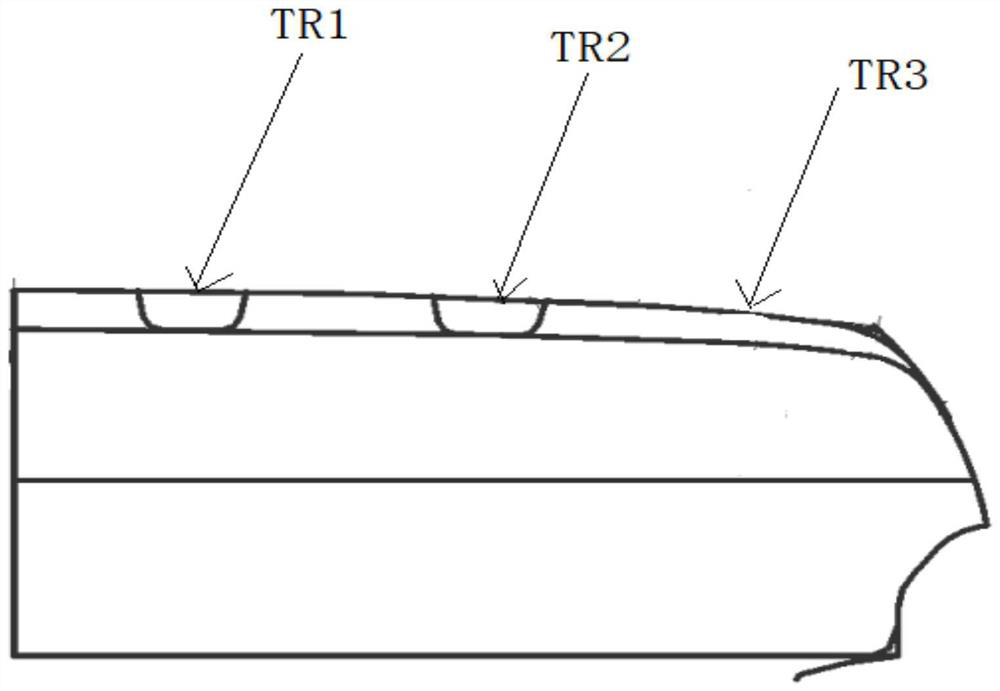

[0024] The first crown arc TR1 is set on one side of the middle part of the outer surface of the crown 1, and the second crown arc TR2 and the shoulder arc TR3 are arranged successively at the middle position of the crown 1 away from the first crown arc TR1. The shoulder arc TR3 is designed as an arc "arch bridge";

[0025] The first crown arc TR1 is the contact part between the tire and the ground, located in the center of the crown 1, and the second crown arc TR2 is the curve connecting the shoulder arc T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com