Movable groove type drying structure

A mobile, drying mechanism technology, applied in drying, drying machine, drying solid materials, etc., can solve the problems of single air outlet, single air outlet and direction, and poor controllability, so as to improve the drying and blowing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

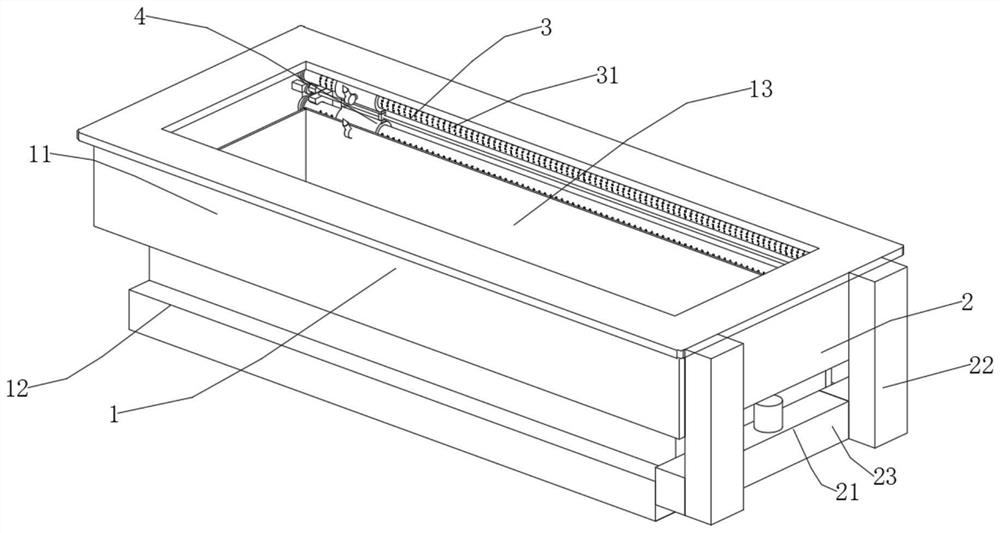

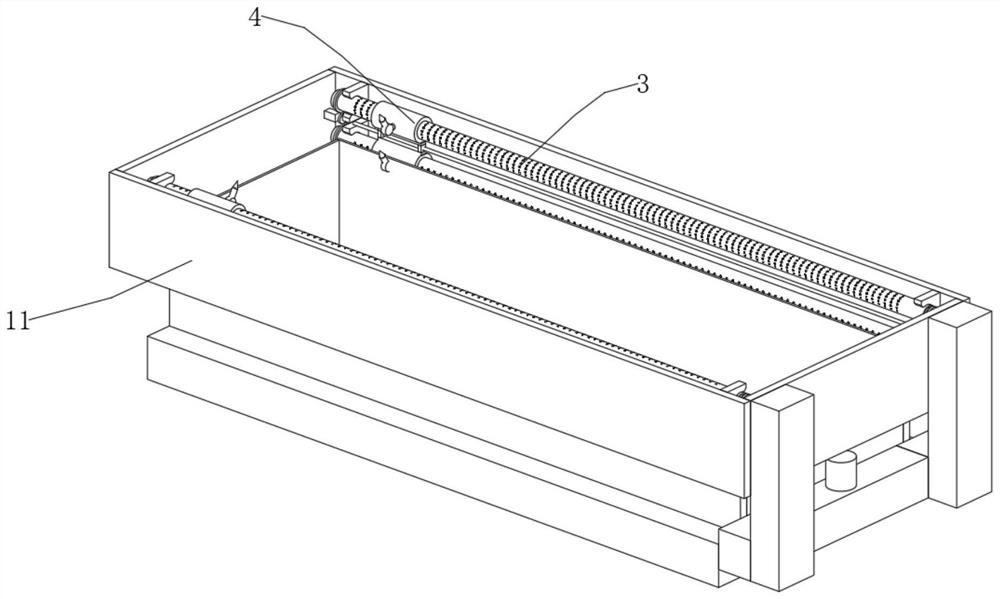

[0040] Such as Figure 1-Figure 7 As shown, a mobile trough drying structure includes a drying mechanism 1 and a circulation mechanism 2. The circulation mechanism 2 is installed outside the drying mechanism 1, and also includes an air duct mechanism 3 for providing drying and blowing and for realizing The mobile drying and blowing mechanism 4 for mobile drying and the opening and closing mechanism 5 for cooperating with the air duct mechanism 3 and the mobile drying and blowing mechanism 4;

[0041] The drying mechanism 1 includes a drying tank 11, a base 12, and a hollow base plate 13. The base 12 is installed at the lower end of the drying tank 11, and the hollow base plate 13 is arranged at the inner bottom of the drying tank 11;

[0042] The circulation mechanism 2 includes an air pump 21, an air intake pipe 22, and a recovery pipe 23. The air pump 21 is installed outside the drying tank 11. An air intake pipe 22 is installed on the upper end of the air pump 21, and a rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com