Test unit for improving WAT test precision and test method thereof

A test unit and test accuracy technology, applied in the direction of single semiconductor device test, measurement power, measurement device, etc., can solve problems such as insufficient test accuracy of machine or pin card, and achieve the effect of convenient and concise test process and reduced test cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

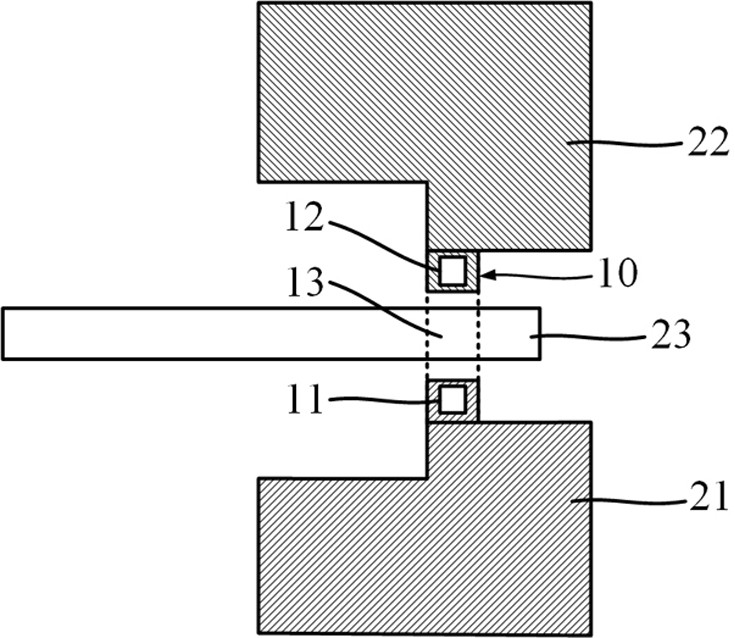

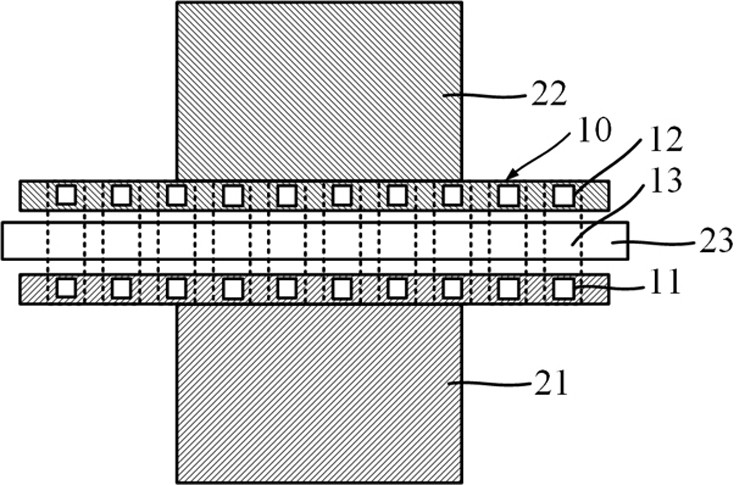

[0034] Such as image 3 As shown, the present embodiment provides a kind of testing unit that improves WAT testing precision, and the testing unit that described improving WAT testing precision comprises:

[0035] The MOS transistor area includes N MOS transistors 10 with the same feature size, N≥2, and the MOS transistor 10 includes a source 11, a drain 12, a gate 13 and a substrate;

[0036] a metal region, located above the MOS transistor region, the metal region includes a source metal region 21, a drain metal region 22, a gate metal region 23 and a substrate metal region;

[0037] interconnecting metal lines, for connecting the source 11 of the MOS transistor 10 to the source metal region 21, the drain 12 to the drain metal region 22, the gate 13 to the The gate metal region 23 is connected, and the substrate is connected to the substrate metal region, so that N MOS transistors 10 are connected in parallel. The test principle of the test unit of described improving WAT ...

Embodiment 2

[0046] The present embodiment provides a kind of test method of the test unit that improves WAT test accuracy, the test method of the test unit that improves WAT test accuracy can use the test unit that improves WAT test accuracy described in embodiment one, described improves WAT test The test method of the test unit of precision comprises the following steps:

[0047] Such as Figure 3 to Figure 4 As shown, step S1 is firstly performed to provide the test unit for improving the test accuracy of WAT.

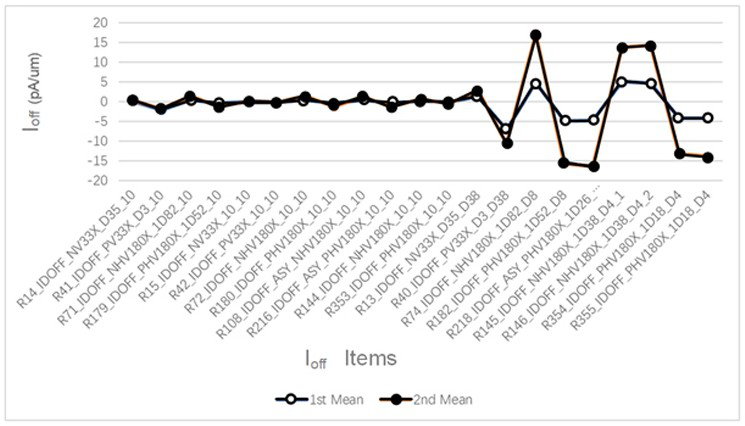

[0048] Such as Figure 3 to Figure 4 Shown, then carry out step S2, the test unit that described improving WAT test accuracy is tested, obtain the leakage current total value I of described test unit all .

[0049] It should be noted here that the test hardware involved in this implementation, such as the test machine and the test needle card, is a hardware device in the prior art, which can directly measure the leakage current total value I of the test unit. all . The num...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com