Solar cell and photovoltaic module

A technology for solar cells and cells, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of easy occurrence of cracks, difficulty in controlling the warpage of the double glass edge of the module backplane, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

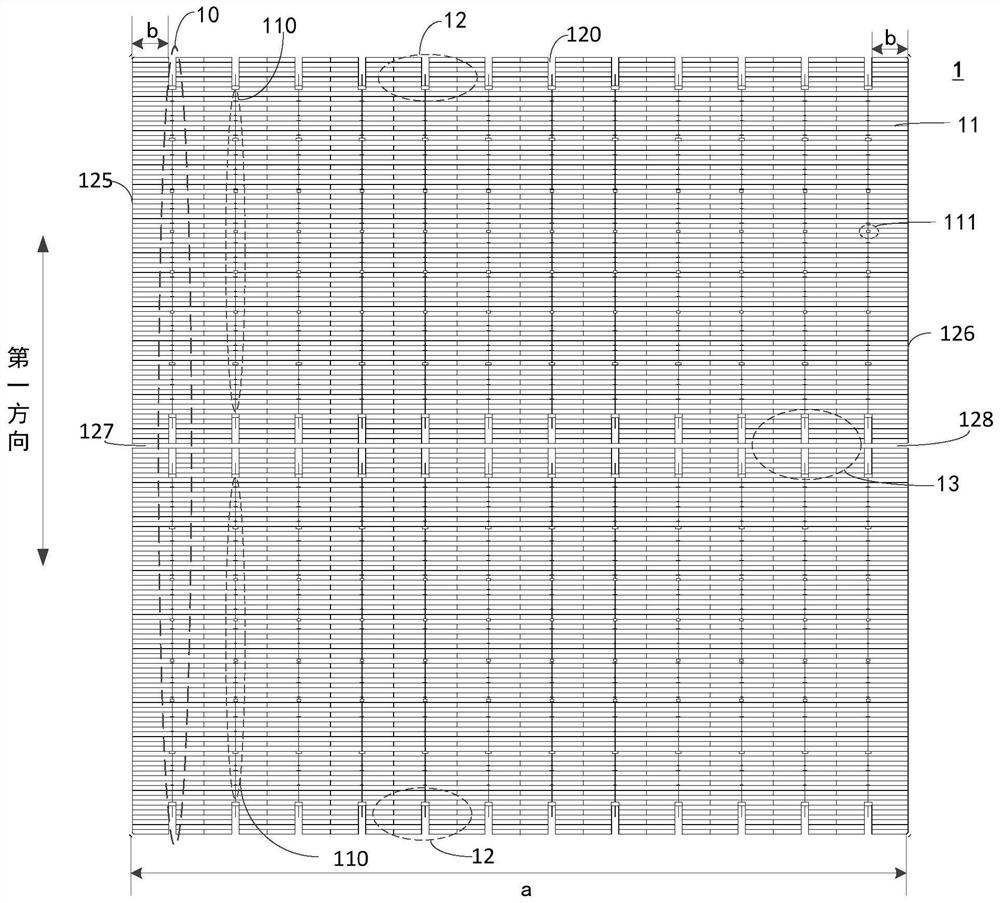

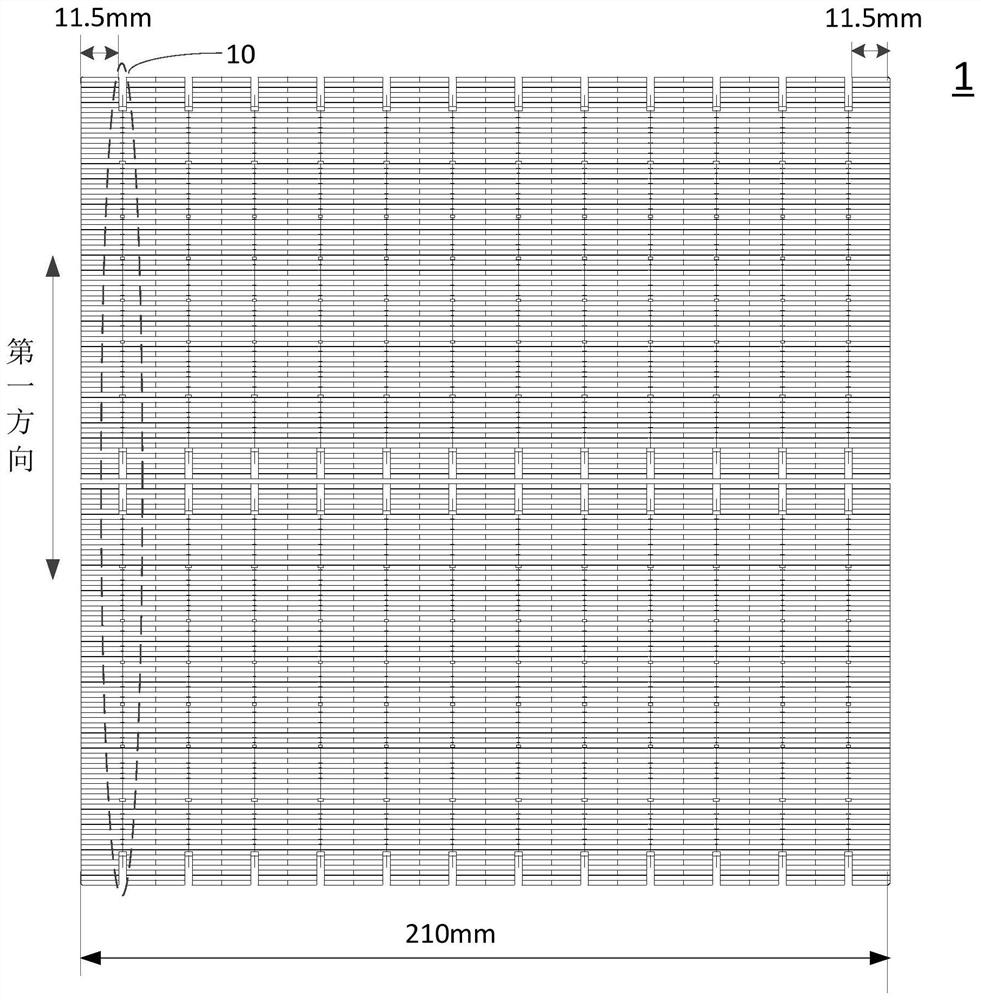

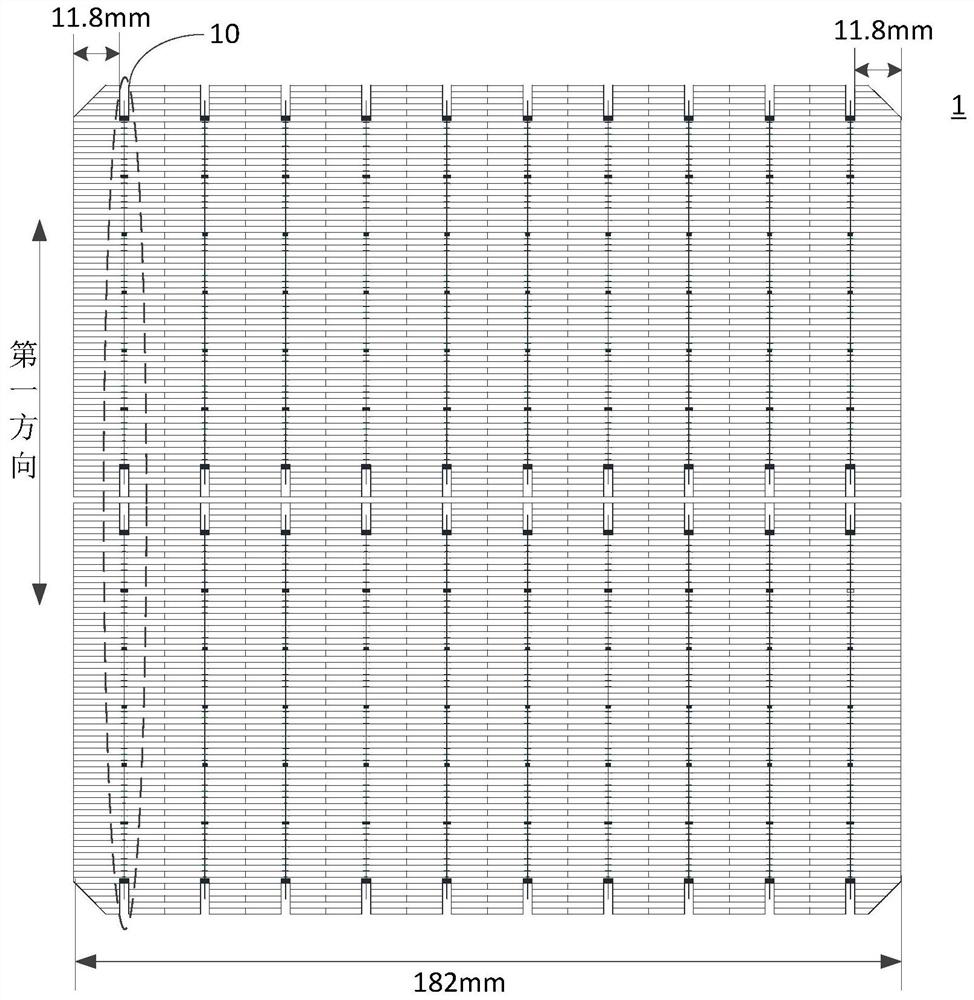

[0033] Embodiments of the present invention are described in detail below, and the embodiments described with reference to the drawings are exemplary, and embodiments of the present invention are described in detail below.

[0034] In the embodiment, the photovoltaic module is composed of a solar cell array, a front sheet, a back sheet, etc. During the production and preparation of the photovoltaic module, it will be reworked due to some abnormality or defect in the module, for example, the busbar of the outermost layer of the cell When the line is too close to the edge, the edge warpage of the backplane such as double-glass glass is unavoidable. During lamination, the edge of the double-glass glass is warped and the edge of the cell is relatively stressed. Therefore, the problem of lamination splitting is prone to occur.

[0035] In order to solve the above-mentioned problems, the solar battery sheet of the embodiment of the present invention improves the main grid line 10 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com