Thermoplastic resin composition, method for preparing same, and molded article

A thermoplastic resin and composition technology, applied in the field of thermoplastic resin composition, its preparation and molded products containing it, can solve the problems of poor chemical resistance and achieve the effect of maintaining mechanical properties and excellent chemical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] A method for preparing a polyester resin commonly used in the field to which the present invention pertains may be used to prepare the polyester resin (A) without particular limitation.

[0043] (B) Vinyl cyanide compound-conjugated diene compound-aromatic vinyl compound graft copolymer

[0044] For example, based on the total weight of the thermoplastic resin composition, the content of the vinyl cyanide compound-conjugated diene compound-aromatic vinyl compound graft copolymer (B) may be 20% by weight to 32% by weight, preferably 22% by weight. % by weight to 32% by weight, more preferably 24% by weight to 32% by weight. Within this range, chemical resistance, processability, injection moldability, and injection stability may be excellent while maintaining mechanical properties, thermal stability, and frictional noise resistance.

[0045] For example, the vinyl cyanide compound-conjugated diene compound-aromatic vinyl compound graft copolymer (B) may be 1 wt% to 20...

Embodiment 1 to Embodiment 11 and comparative example 1 to comparative example 6

[0152] According to the contents shown in Table 1 to Table 3 below, the components shown in Table 1 to Table 3 were charged into the extruder (42ψ) to obtain pellets, and the pellets were injected to obtain sample.

experiment example

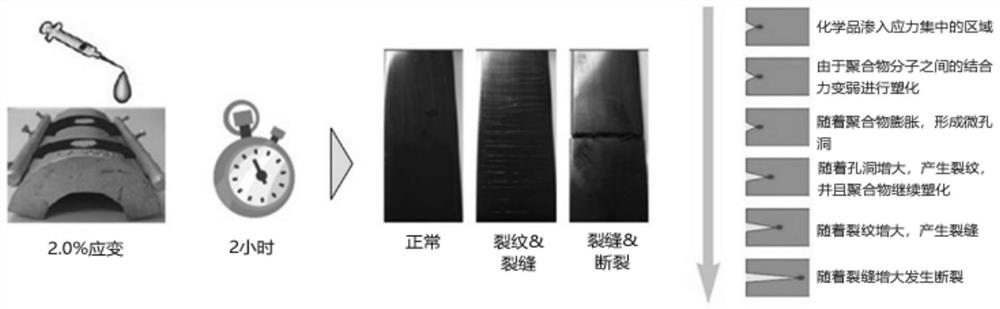

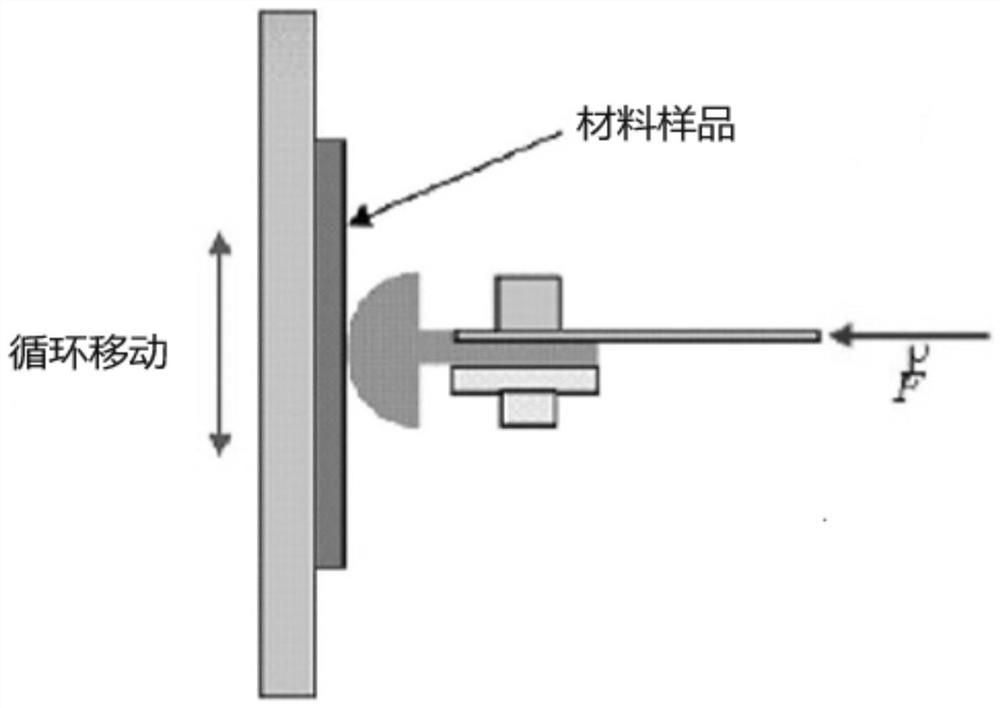

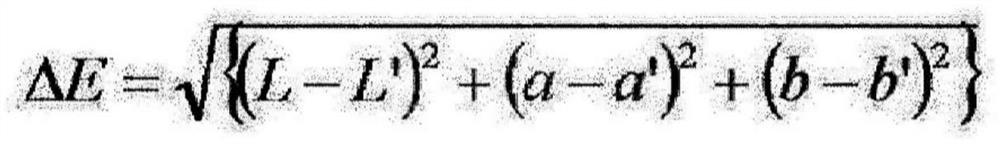

[0154] The properties of the samples prepared in Examples 1 to 11 and Comparative Examples 1 to 6 were measured according to the following methods, and the results are shown in Tables 1 to 3 below.

[0155] Measurement methods

[0156] * Fluidity (melt flow rate): According to ISO 1133, the fluidity is measured at 230° C. for 10 minutes under a load of 10 kg. Here, the unit of fluidity is "g / 10min".

[0157] * Izod impact strength (kJ / m 2 ): According to ISO 180 / 1A, the Izod impact strength is measured at 23°C using notched specimens.

[0158] *Tensile strength (MPa): According to ISO 527, the tensile strength was measured at 50mm / min.

[0159] *Bending strength (MPa) and flexural modulus (MPa): According to ISO 178, using a specimen with a thickness of 1 / 8", under the conditions of a span of 64mm and a test speed of 2mm / min, the bending strength and flexural strength were measured modulus.

[0160] *Heat distortion temperature (°C): According to ISO 75, the heat distor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap