Preparation method and application of microwave response type asphalt-based waterproof binder

An asphalt-based and binder technology, applied in the direction of asphalt material adhesives, adhesives, non-polymer adhesive additives, etc. The problem of surface pavement falling off, to achieve the effect of reducing maintenance cost, excellent fluidity and permeability, and improving fluidity and permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Preparation method of microwave-responsive asphalt-based waterproof binder, including the following steps: nano SiC and nanoFe 3 O 4 According to the mass ratio of 1:1 fully mixed well, the mixture after mixing is added to the asphalt-based waterproof adhesive material and further mixed to obtain a microwave-responsive asphalt-based waterproof adhesive;

[0020] The asphalt-based waterproof bonding material is SBS modified asphalt, the nano SiC particle size is 40 nm, the purity is 99.90%, nano Fe 3 O 4 Particle size is 20 nm, purity is 99.90%; the nano SiC and nano Fe 3 O 4 The total mass accounts for 3% of the total mass of the microwave-responsive asphalt-based waterproof binder;

[0021] Combine nano SiC and nano Fe 3 O 4After mixing well into the mixture, first add a mixture with a mass ratio of 40% to the SBS modified asphalt, mix it at 150 °C for 60 seconds, then add the remaining mixture, and mix it at 150 °C for 90s.

Embodiment 2

[0023] The difference between the present embodiment and Example 1 is: the nano SiC and nanoFe 3 O 4 The total mass accounts for 5% of the total mass of the microwave-responsive bitumen-based waterproof binder.

Embodiment 3

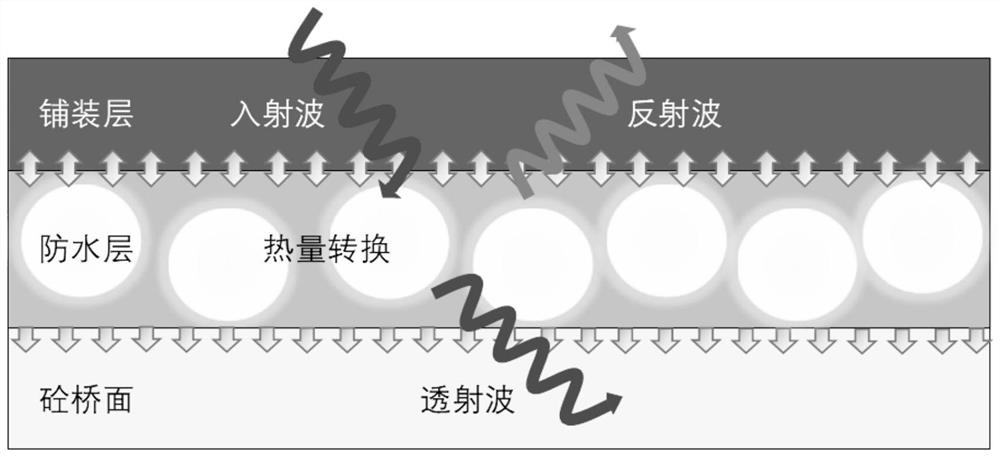

[0025] On the basis of the above embodiment, the present embodiment provides an application of a microwave-responsive asphalt-based waterproof adhesive, comprising the following steps: the prepared microwave-responsive asphalt-based waterproof adhesive is evenly spread on the upper surface of the bridge deck, the microwave-responsive asphalt-based waterproof adhesive after paving constitutes a waterproof adhesive layer, and then the upper surface of the waterproof adhesive layer is constructed, and the microwave maintenance vehicle is used to heat the pavement after the construction of the paving layer, so that the waterproof adhesive layer absorbs the wave to heat up, Thus further fully bonding with the bridge deck and pavement layer;

[0026] Microwave-responsive asphalt-based waterproof binder prepared by automatic spraying equipment, microwave-responsive asphalt-based waterproof binder dosage is 0.8kg / m 2 , sprayed in 3 layers, in which the adjacent upper layer of microwave-re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap