Well cementing and leaking stoppage method

A plugging method and cementing technology, which are used in earth-moving drilling, wellbore/well components, sealing/isolation, etc. The effect of improving quality and reducing complexity of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Reference will now be made in detail to the exemplary embodiments, examples of which are illustrated in the accompanying drawings. The implementations described in the following exemplary embodiments do not represent all implementations consistent with this application. Rather, they are merely examples of approaches consistent with aspects of the application as recited in the appended claims.

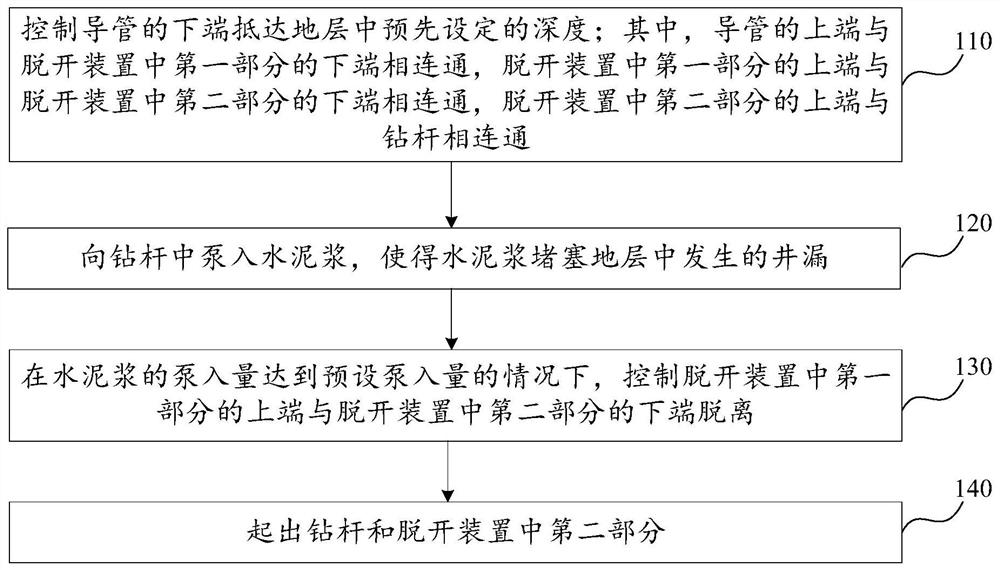

[0050] Please refer to figure 1 , which shows a flowchart of a cementing and plugging method provided by an embodiment of the present application. The method may include the following steps (steps 110-140):

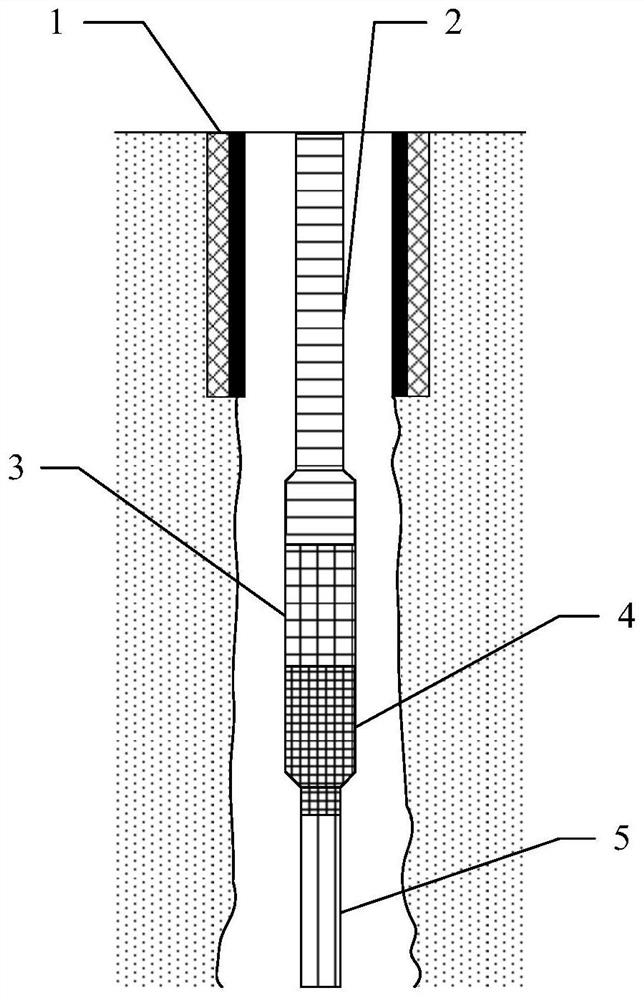

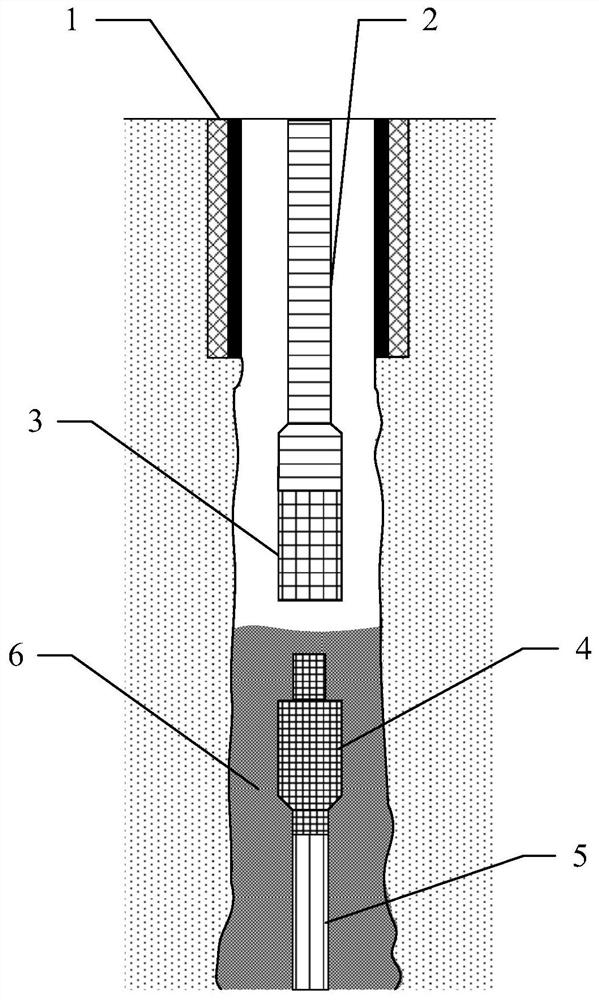

[0051] Step 110, control the lower end of the conduit to reach a preset depth in the formation; wherein, the upper end of the conduit communicates with the lower end of the first part of the release device, and the upper end of the first part of the release device communicates with the second part of the release device. The lower end is connected, and the upper end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com