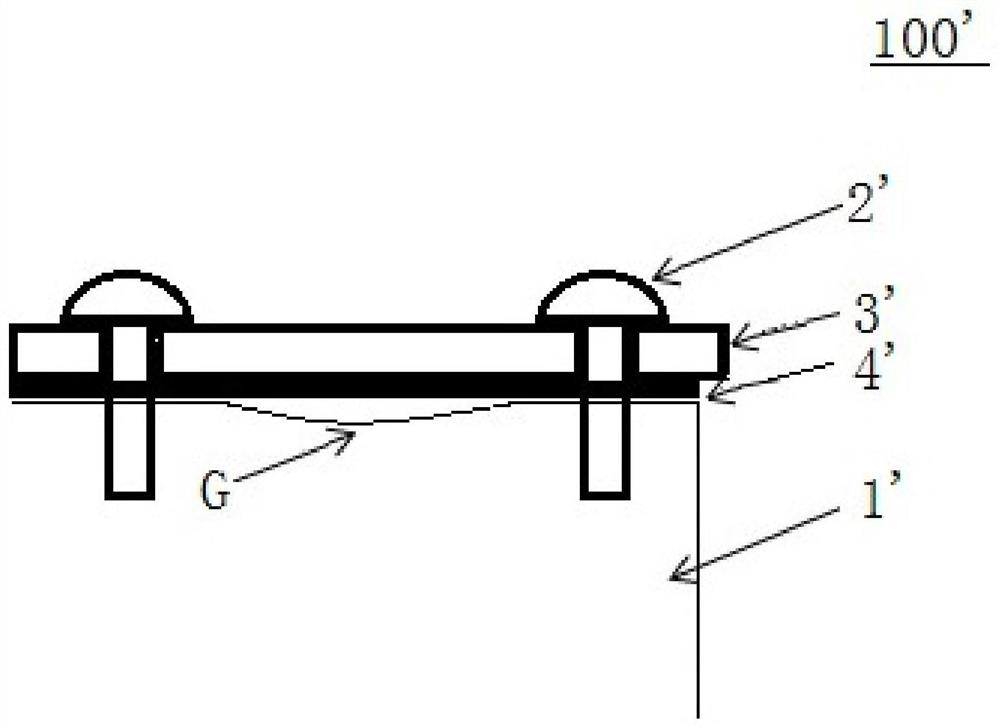

Sealing structure

A technology of sealing structure and sealing parts, which is applied in the direction of engine sealing, mechanical equipment, engine components, etc. It can solve the problems of high resilience of fluorinated resin, reduced sealing effect, and particle drop, so as to improve sealing performance and prolong service life Life, effect of preventing backlash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

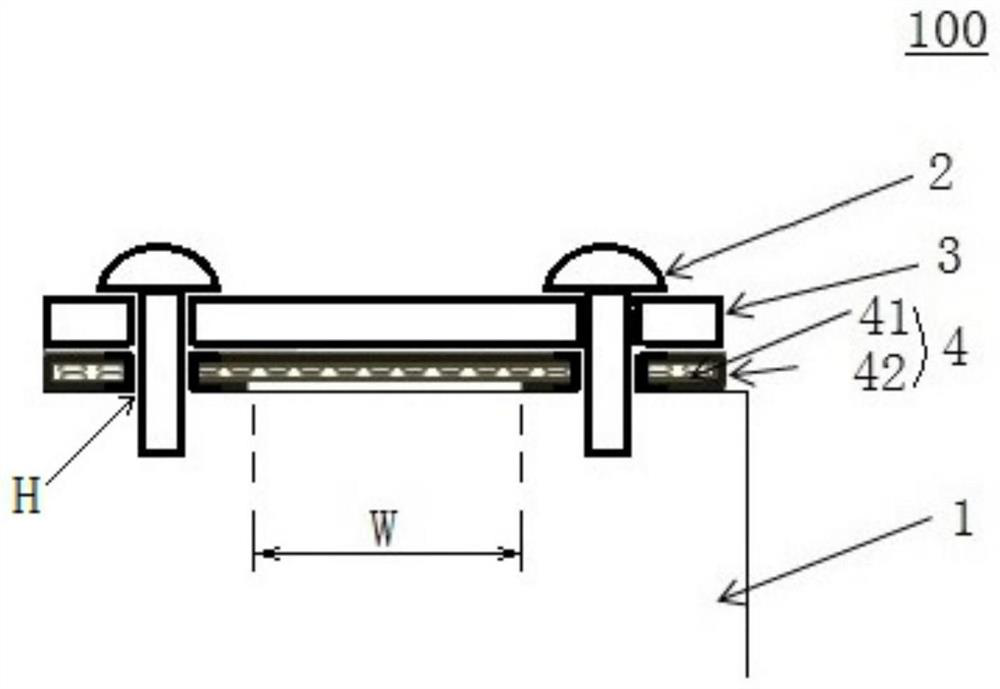

[0042] Reference will now be made in detail to various embodiments of the present invention, examples of which are illustrated in the accompanying drawings and described below. While the invention will be described in conjunction with exemplary embodiments, it will be appreciated that present description is not intended to limit the invention to those exemplary embodiments. On the contrary, the invention is intended to cover not only the exemplary embodiments but also various alternatives, modifications, equivalents and alternatives, modifications, equivalents and various alternatives, modifications, equivalents and other implementations. For ease of explanation and precise definition in the appended claims, the terms "upper", "lower", "inner" and "outer" are used to refer to the positions of features of the exemplary embodiments as shown in the drawings. characteristics are described.

[0043] Such as figure 2 As shown, the sealing structure 100 of this embodiment include...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap