Coarse powder stirring equipment and method for neodymium iron boron production

A mixing equipment, NdFeB technology, applied in the direction of mixer accessories, chemical instruments and methods, recycling technology, etc., can solve the problems of inconvenient loading and unloading storage tanks, and achieve the effect of improving the mixing effect, avoiding danger, and accelerating collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

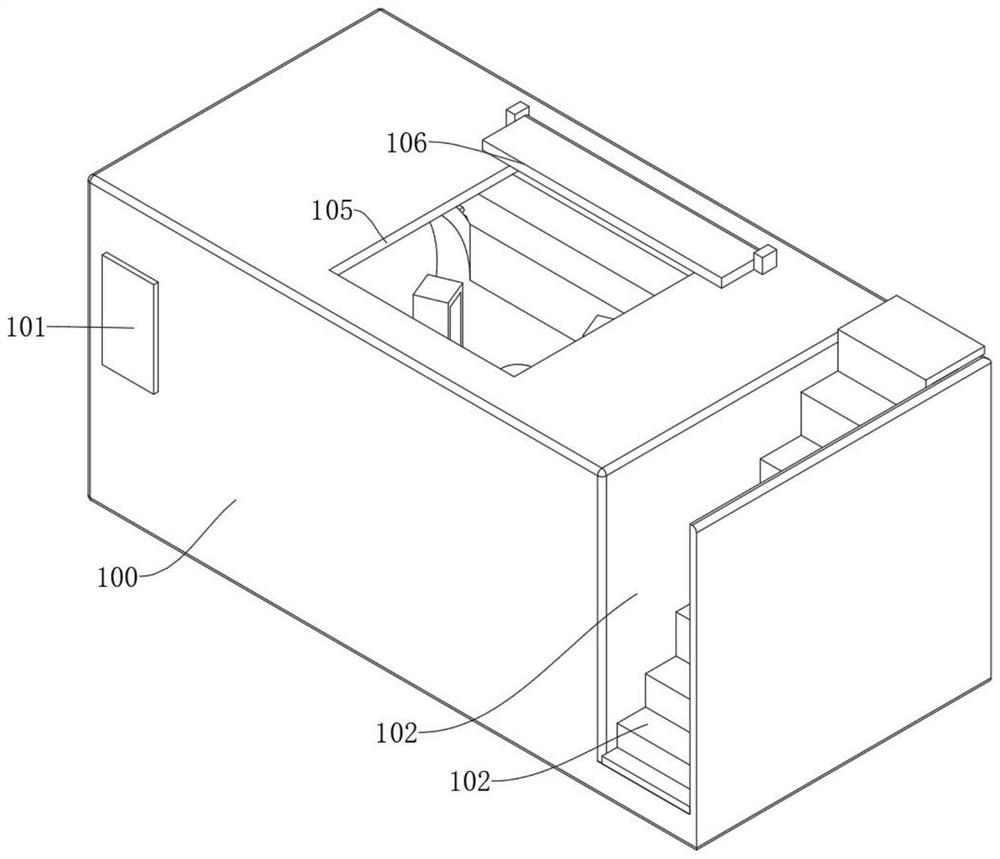

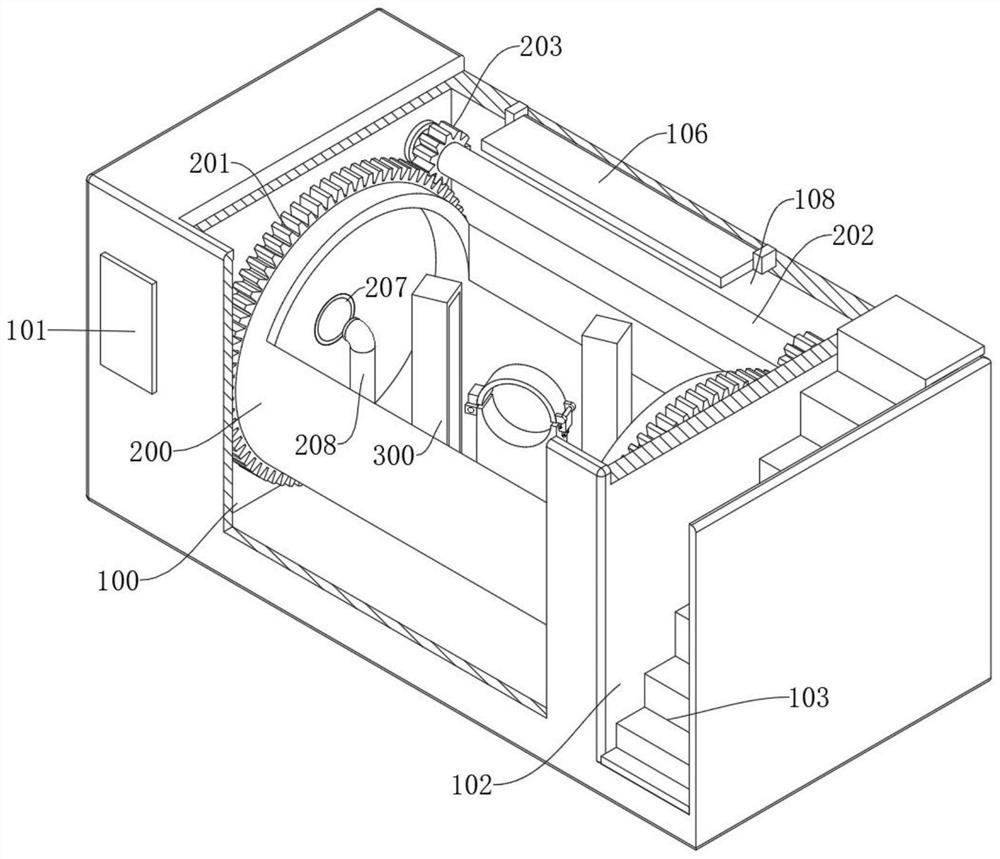

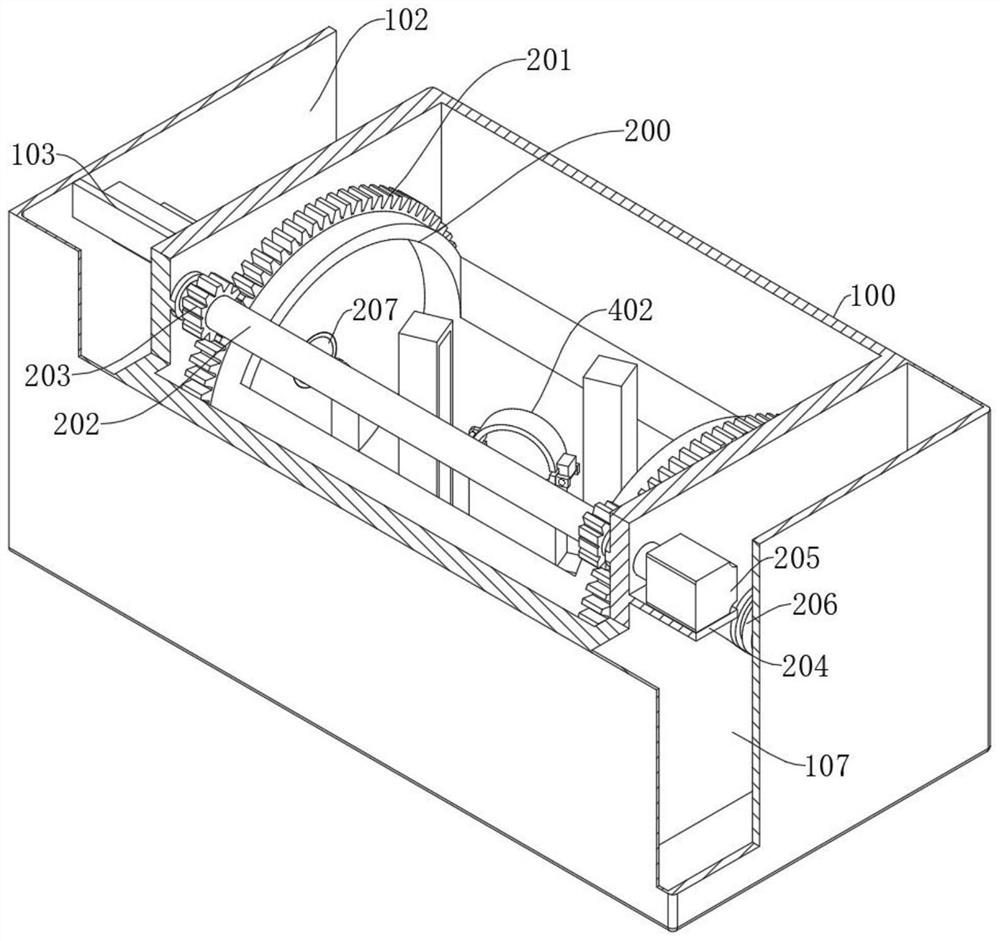

[0036] Example: refer to Figure 1-Figure 6 A coarse powder stirring device for NdFeB production, including an installation box 100, a third installation cavity 108 is opened in the installation box 100, and also includes: a first installation cavity 102 and a second installation cavity 102 respectively disposed on both sides of the third installation cavity 108. Two installation cavities 107; the side wall is provided with a slotted installation cylinder 200, both ends of the installation cylinder 200 are fixedly connected with installation pipes 207, and the two installation pipes 207 are rotatably connected to both sides of the third installation cavity 108 and extend respectively. into the first installation cavity 102 and the second installation cavity 107; the installation post 300 is fixedly connected in the installation cylinder 200, the installation post 300 is provided with a chute 302, and the chute 302 is slidably connected with the second installation plate 400, T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com