Battery power characteristic test method and device

A technology for characteristic testing and battery power, applied in the field of battery power characteristic testing methods and devices, can solve problems such as long test cycles, achieve complete test results, improve test accuracy, and shorten test time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0042] Example 1

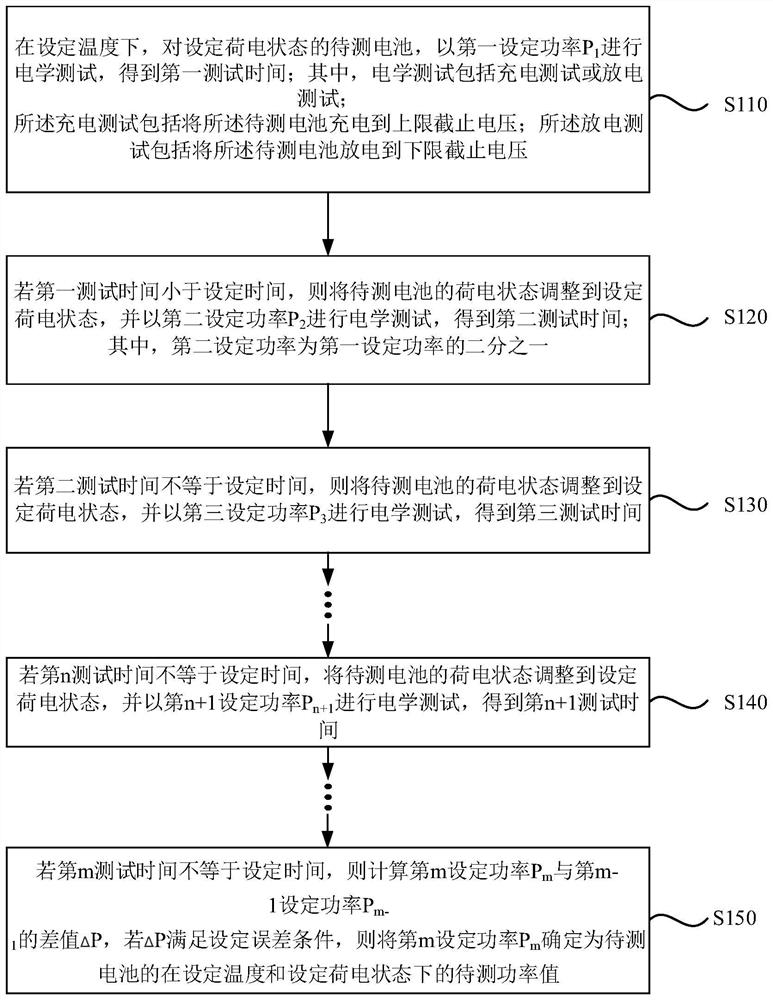

[0043] figure 1 It is a flow chart of a battery power characteristic testing method provided in Embodiment 1 of the present invention. This embodiment can be applied to the battery power characteristic testing situation. The method can be performed by a battery power characteristic testing device, which can be performed by software and / or hardware implementation. refer to figure 1 , the method specifically includes the following steps:

[0044] S110. At the set temperature, for the battery to be tested with the set state of charge, use the first set power P1 Perform an electrical test to obtain a first test time; wherein, the electrical test includes a charge test or a discharge test; the charge test includes charging the battery under test to an upper limit cutoff voltage; the discharge test includes discharging the battery under test to the lower cut-off voltage.

[0045] Specifically, the test equipment is selected according to the parameters of the...

Example Embodiment

[0061] Embodiment 2

[0062] On the basis of the above embodiment, optionally, if the first test time is equal to the set time, the first set power is the power value to be tested of the battery to be tested at the set temperature and the set state of charge; A set power is the maximum power of the test equipment for conducting the electrical test on the battery to be tested. If the first test time is greater than the set time, the battery to be tested is subjected to the next set state of charge electrical test at the set temperature.

[0063] Specifically, when the first test time is equal to the set time, the first set power for the electrical test of the battery under test is the power required for the power characteristic test. When the first test time is greater than the set time, it indicates that the first set power is too small, and the first set power needs to be increased, but at this time the first set power has reached the limit of the maximum power of the chargin...

Example Embodiment

[0074] Embodiment 3

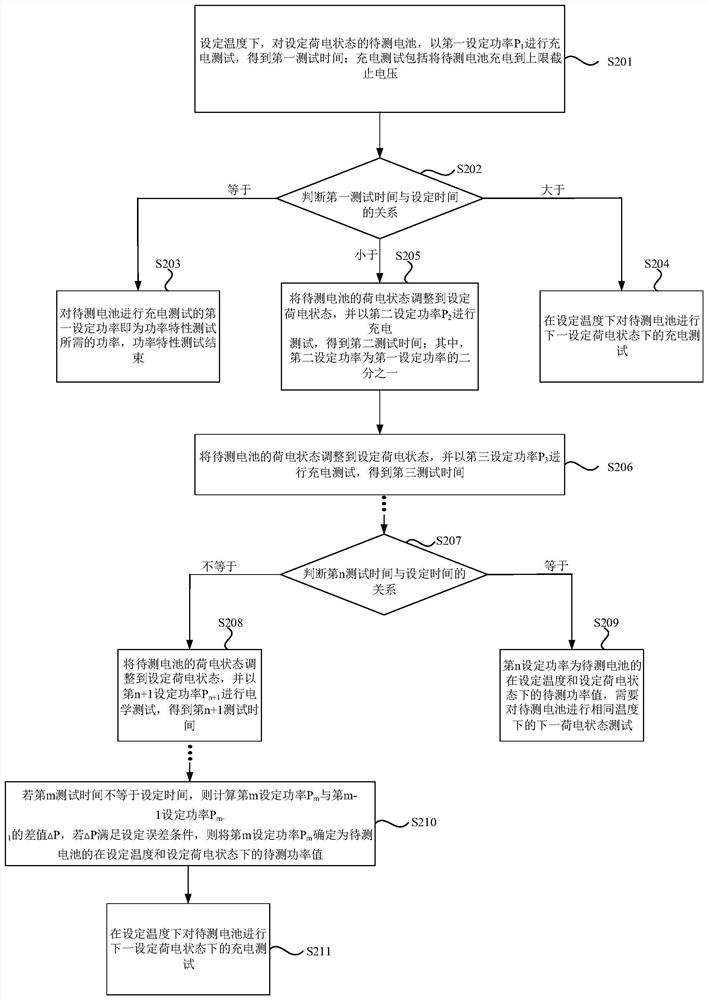

[0075] figure 2 This is a flowchart of a method for testing battery charging power characteristics provided in Embodiment 3 of the present invention. Refer to figure 2 , the following is an example of the power characteristic test of the battery to be tested:

[0076] S201. Under the set temperature, for the battery to be tested with the set state of charge, use the first set power P 1 A charging test is performed to obtain the first test time; the charging test includes charging the battery to be tested to the upper limit cut-off voltage.

[0077] S202. Determine the relationship between the first test time and the set time. If the first test time is equal to the set time, execute S203; if the first test time is greater than the set time, execute S204; if the first test time is less than the set time, execute S205.

[0078]S203 , the first set power for the charging test of the battery to be tested is the power required for the power characteristic...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap