Visual calibration method for manipulator flowing along production line

A calibration method and manipulator technology, applied in the field of visual calibration, can solve problems such as difficulty in improving manipulator tempo, achieve the effect of shortening work tempo and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

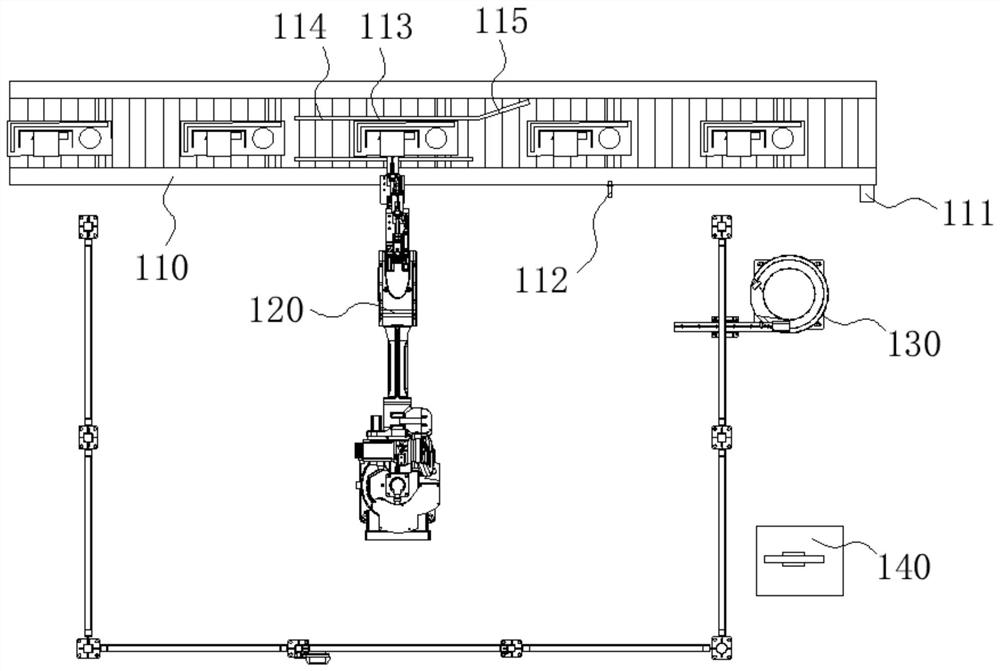

[0031] like figure 1 As shown, this embodiment provides a visual guidance device for manipulators to follow the flow of the production line, which includes an assembly line 110 and a manipulator 120. The manipulator 120 is used to follow the flow of the assembly line 110, thereby realizing the tracking of the products to be processed so as to realize the production of the products to be processed. Dynamic processing (including assembly and disassembly); one side of the manipulator 120 is provided with a feeding mechanism 130 and an electric control cabinet 140, and the electric control cabinet 140 is used to control the manipulator 120 to track and assemble the products to be processed flowing on the assembly line 110 or disassembled.

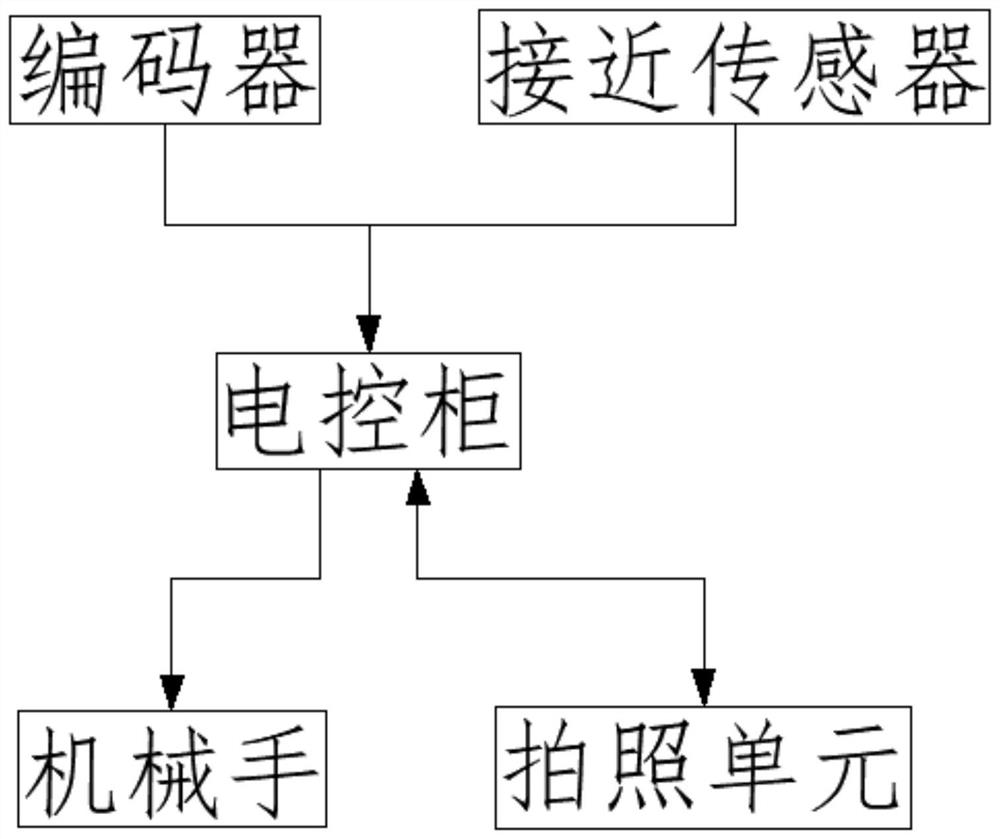

[0032] combine figure 2 As shown, based on the above-mentioned visual guidance device for manipulators to follow the flow of the production line, this embodiment also provides a visual calibration method for the manipulators to follow the flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com