A kind of CNC device processing lathe for graphite tower section

A lathe and graphite technology, which is applied in the field of CNC device processing lathes for graphite tower sections, can solve the problems of normal use of processing lathes, inability to collect and process dust particles, and inability to reduce the interference of the manufacturing quality of graphite tower sections of lathes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

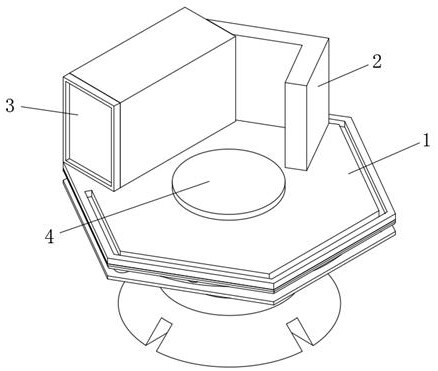

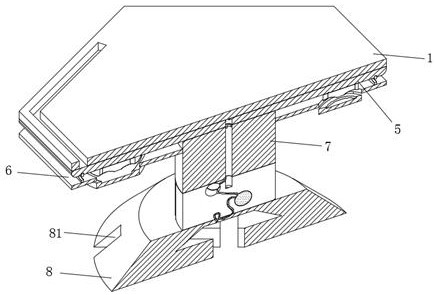

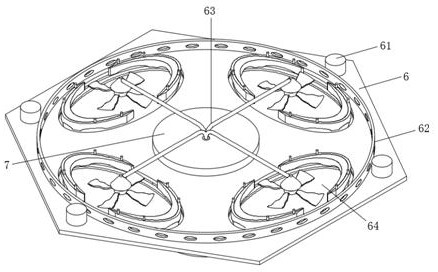

[0030] see Figure 1-7 , The present invention provides a technical solution: a CNC device processing lathe for graphite tower sections, including a lathe top plate 1, the top of the lathe top plate 1 is installed with a processing component 2 for processing the graphite tower section, and the top of the lathe top plate 1 is installed. In order to control the numerical control mechanism 3 of the lathe, the top middle of the top plate 1 of the lathe is installed with a fixed platform 4 for fixing the graphite tower section, the lower end of the lathe top plate 1 is installed with a No. The middle part of the lower end of the number plate 5 is connected to the column foot 7 through the second plate 6. The inner part of the column foot 7 is provided with a guide cavity 71. The lower end of the column foot 7 is connected with a storage body 72 for storing dust and water vapor. The bottom end of the column foot 7 A horseshoe table 8 is installed, and the bottom surface of the horse...

Embodiment 2

[0036] like Figure 1-7 As shown, the present invention provides a technical solution: a CNC device processing lathe for graphite tower sections, comprising a lathe top plate 1, the top of the lathe top plate 1 is installed with a processing component 2 for processing the graphite tower section, and the top of the lathe top plate 1 is installed. A numerical control mechanism 3 for controlling the lathe is installed, a fixed platform 4 for fixing the graphite tower section is installed in the top middle of the top plate 1 of the lathe, a No. , the middle part of the lower end of the first plate 5 is connected with the column foot 7 through the second plate 6, the inner part of the column foot 7 is provided with a guide cavity 71, and the lower end of the column foot 7 is connected with a storage body 72 for storing dust and water vapor. The bottom end is provided with a horseshoe table 8, and the bottom surface of the horseshoe table 8 is provided with a cross cavity groove 81 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com