Glue injection production device for rubber boots

A production device and glue injection technology, which is applied to other household appliances, household appliances, household components, etc., can solve the problems of low glue control efficiency and cumbersome steps, and achieve the effect of improving efficiency and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Specific embodiments of the present invention will be described in detail below. It should be understood that the specific embodiments described herein are only used to illustrate and explain the present invention, but not to limit the present invention.

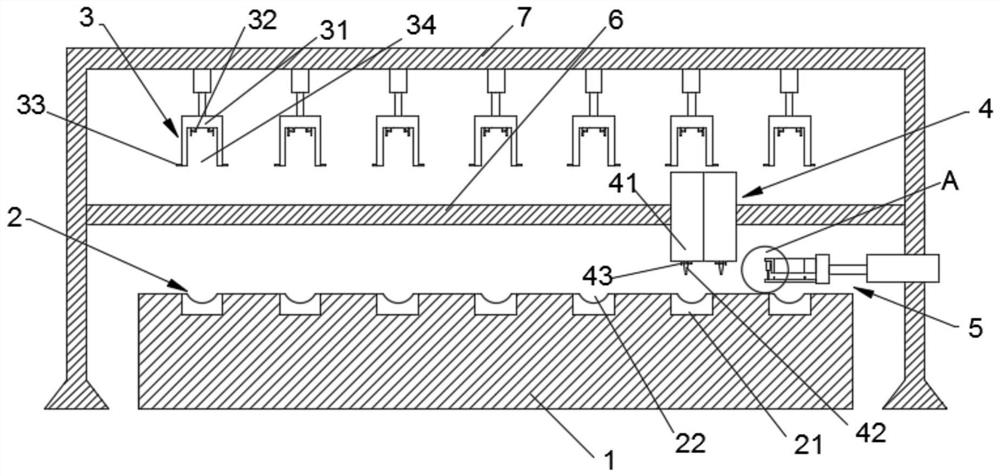

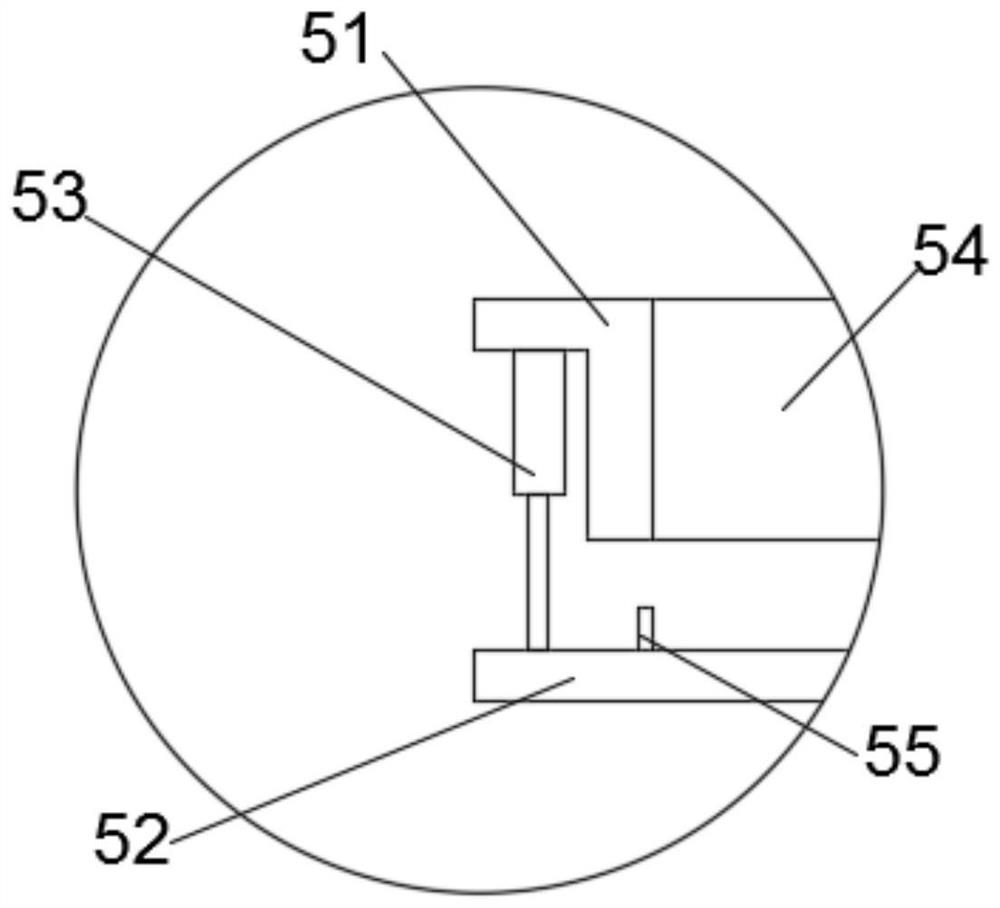

[0033] like Figure 1-Figure 3 As shown, the present invention provides a glue injection production device for rubber boots, the glue injection production device for rubber boots includes a workbench 1, and a plurality of A set of sole modules 2, a plurality of shoe upper clamping portions 3 provided corresponding to each set of the sole modules 2, a glue injection assembly 4 located above the sole module 2 and capable of moving along the extension direction of the workbench 1 , and the cutting structure 5 arranged movably along the extending direction; wherein,

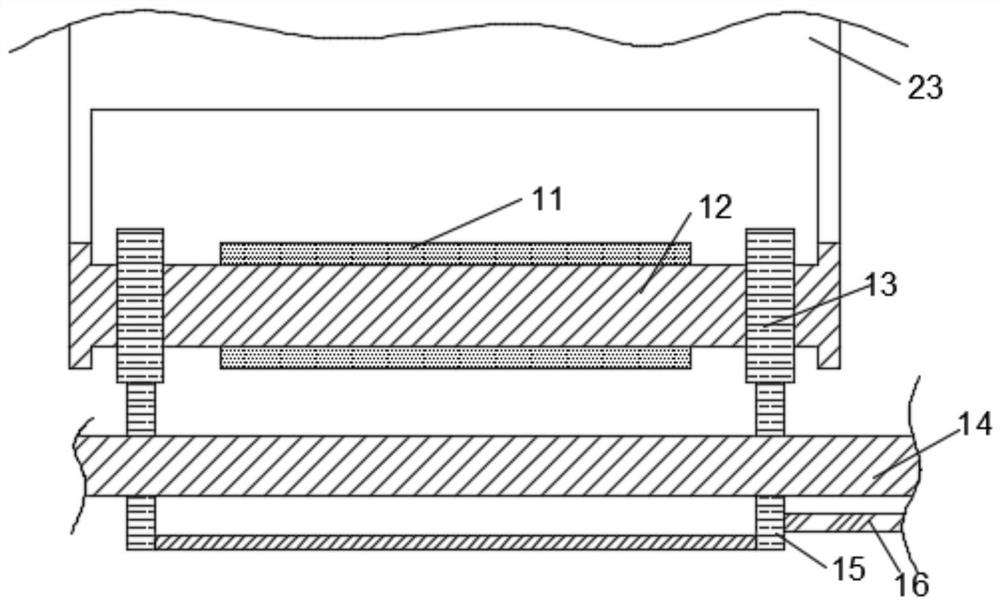

[0034] Each set of the shoe sole modules 2 at least includes an upper mold 23 and a lower mold 21 that are cooperatively formed as a sole mold cavity;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com