Automatic fertilizer sampler

An automatic sampler and fertilizer technology, applied in sampling devices, agricultural gas emission reduction, transportation and packaging, etc., can solve the problems of high labor intensity, low work efficiency, missed detection of abnormal products, etc., and achieve simple equipment and fast sampling time Precise, less parts effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

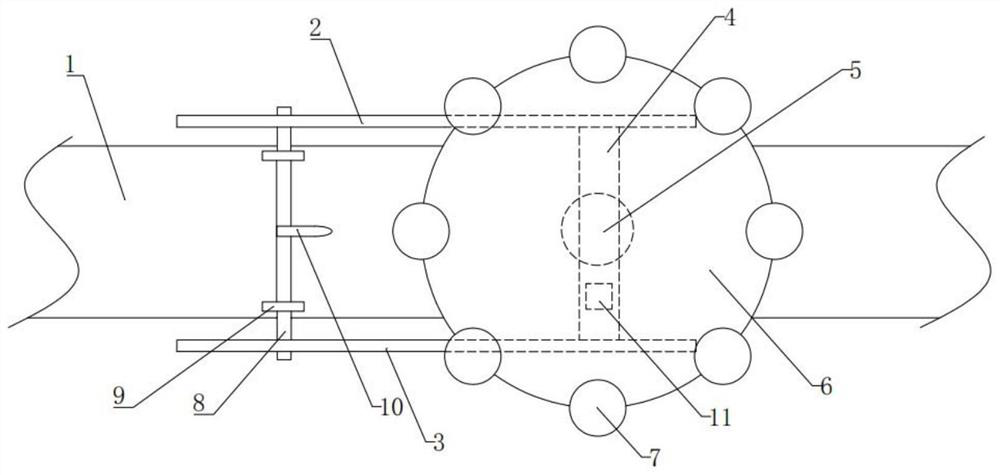

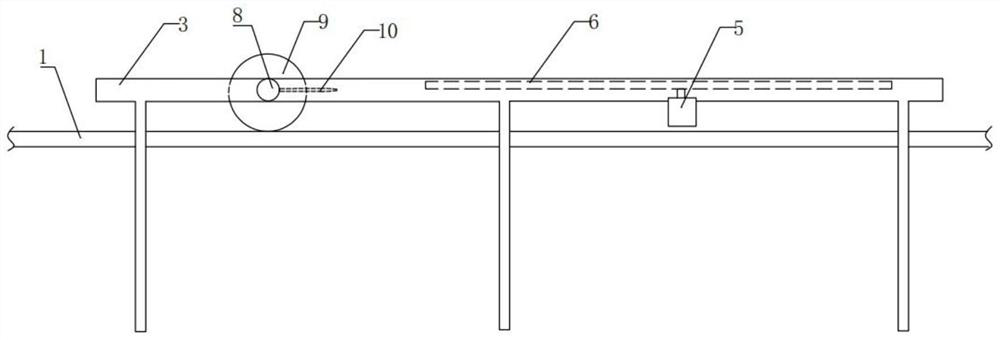

[0026] A fertilizer automatic sampler such as figure 1 and figure 2 shown:

[0027] A support frame is installed above the fertilizer conveyor belt 1 , and the support frame in this embodiment is composed of a first frame 2 , a second frame 3 and a beam 4 . The first bracket 2 and the second bracket 3 are respectively located on both sides of the fertilizer conveyor belt 1, the beam 4 is fixed between the first bracket 2 and the second bracket 3, and a turntable 6 is placed on the first bracket 2 and the second bracket 3, A motor 5 is installed on the bottom of the turntable 6 , and the motor 5 is fixed on the beam 4 . The output shaft of the motor 5 is connected with the turntable 6 to drive the turntable 6 to rotate. A governor 11 is installed on the beam 4 , and the governor 11 is used to adjust the rotational speed of the motor 5 .

[0028] The edge of the turntable 6 is evenly provided with 8 circular grooves of the same size, the included angle formed by the center ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com